HPL Tubes|Seamless Phosphated HPL Tube

VIEW MORE+- What is the Difference between Hastelloy C-276 and C-2000?

- Introduce Titanium Alloy Coiled Tubing

- What is Coiled Tubing?

- Inconel vs Incoloy Nickel Alloy Tube

- Introduce St 37.4 Black Phosphate Hydraulic Seamless Tube

- Inconel vs Hastelloy: Corrosion Resistance & High-Temp Applications

- Monel 400 vs. Stainless Steel: A Guide to Selecting Materials for Corrosive Environments

- Inconel 600 vs 601 vs 625: Nickel-based alloy pipe performance comparison and selection guide

- Difference between Monel 400 and Monel K-500 Tubes

- Classification of Nickel and Nickel Alloy

EN 10305-4 Hydraulic Steel Tube

EN 10305-4 is a European standard that specifies the technical delivery conditions for seamless cold-drawn hydraulic steel tubes. These tubes are primarily used in hydraulic and pneumatic systems.

What is EN 10305-4 hydraulic steel tube?

EN 10305-4 is a European standard that specifies the technical delivery conditions for seamless cold drawn precision steel tubes used in hydraulic and pneumatic power systems. These tubes are typically employed in applications where high precision and smooth surface finish are crucial for optimal performance, such as in hydraulic cylinders, automotive industry, and precision engineering. EN 10305-4 ensures the tubes meet specific dimensional tolerances, mechanical properties, and surface characteristics required for their intended use, contributing to the reliability and efficiency of hydraulic systems.

EN 10305-4 Hydraulic Steel Tube Material Grade:

The material grade for hydraulic steel tubes as per EN 10305-4 can vary, but commonly used grades include E235, E355, and E410. These grades denote the minimum yield strength and chemical composition of the steel.

EN 10305-4 Hydraulic Steel Tube Chemical Composition:

The chemical composition of hydraulic steel tubes depends on the specific material grade. However, typical composition ranges for common grades are as follows:

- E235: Carbon (C) ≤ 0.17%, Manganese (Mn) ≤ 1.20%, Phosphorus (P) ≤ 0.025%, Sulfur (S) ≤ 0.025%

|

Element |

Chemical Composition (% max) |

|

Carbon (C) |

≤ 0.17 |

|

Manganese (Mn) |

≤ 1.20 |

|

Phosphorus (P) |

≤ 0.025 |

|

Sulfur (S) |

≤ 0.025 |

- E355: Carbon (C) ≤ 0.22%, Manganese (Mn) ≤ 1.60%, Phosphorus (P) ≤ 0.025%, Sulfur (S) ≤ 0.025%

|

Element |

Chemical Composition (% max) |

|

Carbon (C) |

≤ 0.22 |

|

Manganese (Mn) |

≤ 1.60 |

|

Phosphorus (P) |

≤ 0.025 |

|

Sulfur (S) |

≤ 0.025 |

- E410: Carbon (C) ≤ 0.20%, Manganese (Mn) ≤ 1.60%, Phosphorus (P) ≤ 0.025%, Sulfur (S) ≤ 0.025%

|

Element |

Chemical Composition (% max) |

|

Carbon (C) |

≤ 0.20 |

|

Manganese (Mn) |

≤ 1.60 |

|

Phosphorus (P) |

≤ 0.025 |

|

Sulfur (S) |

≤ 0.025 |

EN 10305-4 Hydraulic Steel Tube Mechanical Properties:

The mechanical properties of hydraulic steel tubes are defined by their material grade. Typical mechanical properties for commonly used grades include:

- E235: Minimum Yield Strength ≥ 235 MPa, Minimum Tensile Strength ≥ 360 MPa, Elongation ≥ 25%

|

Property |

Value |

|

Minimum Yield Strength |

≥ 235 MPa |

|

Minimum Tensile Strength |

≥ 360 MPa |

|

Elongation |

≥ 25% |

- E355: Minimum Yield Strength ≥ 355 MPa, Minimum Tensile Strength ≥ 490 MPa, Elongation ≥ 22%

|

Property |

Value |

|

Minimum Yield Strength |

≥ 355 MPa |

|

Minimum Tensile Strength |

≥ 490 MPa |

|

Elongation |

≥ 22% |

- E410: Minimum Yield Strength ≥ 410 MPa, Minimum Tensile Strength ≥ 550 MPa, Elongation ≥ 22%

|

Property |

Value |

|

Minimum Yield Strength |

≥ 410 MPa |

|

Minimum Tensile Strength |

≥ 550 MPa |

|

Elongation |

≥ 22% |

EN 10305-4 Hydraulic Steel Tube Delivery Condition:

Hydraulic steel tubes are delivered in a normalized or normalized rolled condition. This means that they are heat-treated to obtain a desired microstructure and mechanical properties.

|

Designation |

Symbol |

Description |

|

Cold finished (hard) |

BK(+C) |

|

|

Cold finished (Soft) |

BKW |

|

|

Cold finished and stress-relieved |

BKS(+SR) |

|

|

Annealed |

GBK(+A) |

The last Cold forming process is followed by annealing in a controlled atmosphere. |

|

Normalized |

NBK(+N) |

The last cold forming process is followed by annealing above the upper transformation point in a controlled atmosphere. |

EN 10305-4 Hydraulic Steel Tube Permissible Variations in Dimensions:

EN 10305-4 specifies the permissible variations in dimensions for hydraulic steel tubes, including tolerances on outer diameter, wall thickness, and length. These tolerances ensure the tubes meet the required specifications for their intended applications.

|

Outer Diameter |

Allowable tolerance |

special tolerance |

||

|

GB/T3639 |

DIN2391 |

OD |

WT |

|

|

4mm-20mm |

±0.10mm |

±0.08mm |

±0.05mm |

±0.05mm |

|

20mm-30mm |

±0.10mm |

±0.08mm |

±0.08mm |

±0.08mm |

|

31mm-40mm |

±0.15mm |

±0.15mm |

±0.10mm |

±0.08mm |

|

41mm-60mm |

±0.20mm |

±0.20mm |

±0.15mm |

±0.15mm |

|

61mm-80mm |

±0.30mm |

±0.30mm |

±0.20mm |

±0.20mm |

|

81mm-120mm |

±0.45mm |

±0.45mm |

±0.30mm |

±0.30mm |

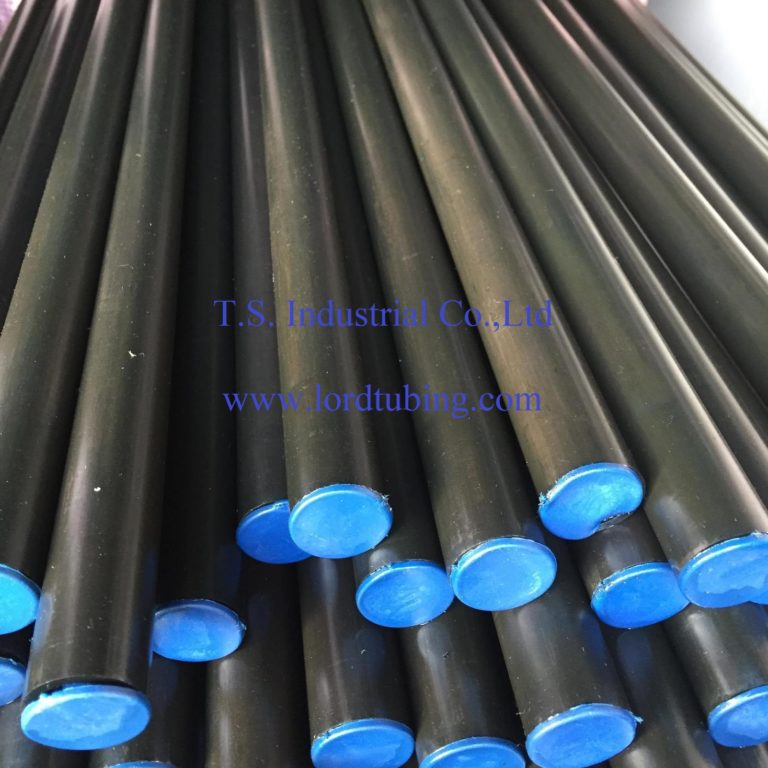

EN 10305-4 Hydraulic Steel Tube Surface Treatment:

The standard does not specify any specific surface treatment for hydraulic steel tubes. However, depending on the application and customer requirements, the tubes may undergo processes such as phosphating, galvanizing, or coating to enhance corrosion resistance.

EN 10305-4 Hydraulic Steel Tube Advantages:

Hydraulic steel tubes manufactured according to EN 10305-4 offer several advantages, including:

- High precision: The cold-drawn process ensures tight dimensional tolerances and smooth surface finish, making them suitable for precise hydraulic applications.

- Good mechanical properties: The specified mechanical properties ensure the tubes can withstand high pressure and provide reliable performance.

- Corrosion resistance: Proper surface treatment or coating can enhance the corrosion resistance of the tubes, making them suitable for challenging environments.

EN 10305-4 Hydraulic Steel Tube Applications:

EN 10305-4 hydraulic steel tubes are highly versatile components that find applications across various industries due to their durability, precision, and reliability in hydraulic transmission systems.

1. Hydraulic Cylinders: These tubes are commonly employed in the manufacturing of hydraulic cylinders used in various machinery and equipment, including construction machinery, agricultural equipment, and industrial machinery.

2. Hydraulic and Pneumatic tubing: EN 10305-4 tubes are suitable for use in hydraulic and pneumatic piping systems, where they facilitate the efficient transmission of fluids or gases under pressure. These systems are found in industries such as manufacturing, automation, and heavy equipment.

3. Power Steering Systems: In the automotive industry, these tubes play a crucial role in power steering systems, enabling smooth and responsive steering functionality in vehicles. They provide the necessary strength and integrity to withstand the pressures and stresses experienced in power steering applications.

4. Fuel Injection Systems: EN 10305-4 tubes are also utilized in fuel injection systems, particularly in diesel engines. They help deliver fuel with precision and consistency, contributing to the efficient performance of the engine while minimizing emissions.

5. Suspension Systems: Suspension systems in vehicles, especially those designed for heavy-duty applications such as trucks and off-road vehicles, benefit from the use of EN 10305-4 tubes. These tubes provide structural support and enable the smooth operation of suspension components, enhancing ride comfort and stability.

The widespread use of EN 10305-4 hydraulic steel tubes across automotive, construction, machinery, and general engineering sectors underscores their importance in facilitating reliable and efficient hydraulic transmission in various applications. Their high-quality construction and adherence to industry standards make them indispensable components in numerous industrial processes and systems.

EN 10305-4 Hydraulic Steel Tube

-

-

Automotive Steel Tube|Automotive tubing

VIEW MORE+ -

Cold Drawn Hydraulic Tubes|Cold Drawn Galvanized Hydraulic Steel Tube

VIEW MORE+

请输入搜索关键字

确定