Monel 400 vs. Stainless Steel: A Guide to Selecting Materials for Corrosive Environments

In highly corrosive environments such as chemical and marine engineering, it is crucial to choose the right material. Corrosion not only causes equipment downtime and affects production efficiency, but also significantly increases maintenance costs. According to a report by NACE (National Association of Corrosion Engineering), the global economic losses caused by corrosion account for 3-4% of GDP. Therefore, how to choose cost-effective materials with excellent corrosion resistance has become a core issue that companies need to solve urgently.

|

|

Monel 400 |

Stainless Steel |

|

Density (g/cm3) |

8.8 |

7.9 |

|

Melting Range (°C) |

1300-1350 |

1400-1450 |

|

Thermal Conductivity (W/m·K) |

21.8 |

16.2 |

|

Thermal Expansion (10⁻⁶/°C) |

13.9 |

17.2 |

|

Elastic Modulus (GPa) |

179 |

193 |

|

|

Monel 400 |

Stainless Steel |

|

Sulfuric acid |

Excellent in low concentration (<70%), low temperature sulphuric acid |

Only suitable for low concentration, low temperature sulphuric acid |

|

Hydrochloric acid |

Good in low concentration, low temperature HCl |

Not recommended for use in HCl environments |

|

Hydrofluoric acid |

Excellent in low concentration HF |

Not recommended for use in HF environments |

|

|

Monel 400 |

Stainless Steel |

|

Tensile Strength (MPa) |

550-780 |

515-690 |

|

Yield Strength (MPa) |

240-450 |

205-310 |

|

Elongation (%) |

40-50 |

40-50 |

|

Hardness (HB) |

150-250 |

170-210 |

|

Impact toughness (J) |

100-15 |

80-120 |

|

Fatigue strength (MPa) |

250-350 |

200-300 |

|

Application areas |

Monel 400 |

Stainless steel |

|

Marine engineering |

Seawater pump shaft, subsea valve |

Hull structure, non-seawater contact parts |

|

Oil and gas |

High-sulfur oil well casing, refinery heat exchanger |

Normal pressure storage tanks, gas pipelines |

|

Chemical equipment |

Hydrofluoric acid reactor, acetic acid evaporator |

Ordinary acid and alkali storage tanks, ventilation systems |

|

|

Monel 400 |

Stainless Steel |

|

Corrosive environment |

Highly corrosive environment |

Medium to low corrosive environment |

|

Corrosive media |

Seawater, chloride ion-containing media Strongly acidic media |

Low concentration acid and alkaline medium Environment without chloride ions or oxidizing medium |

|

Application temperature |

High temperature and pressure Low temperature environment |

Room temperature |

|

Budget |

Sufficient budget, focus on full life cycle cost |

Budget is limited but certain corrosion resistance is required |

|

Mechanical performance requirements |

Requires high strength, high toughness and fatigue resistance |

Require certain strength and toughness |

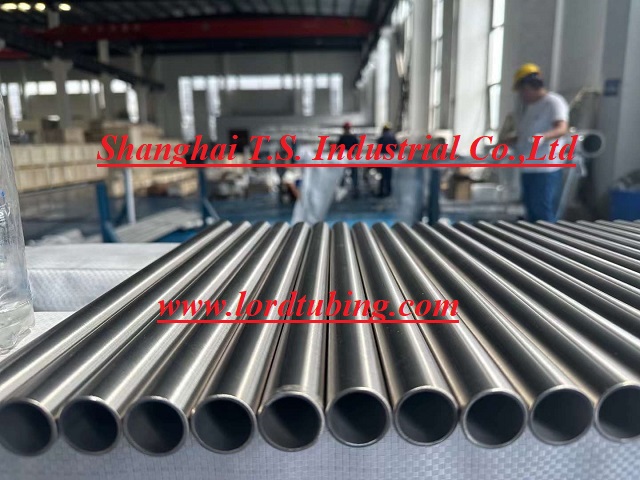

Monel 400 Nickel Alloy Tube

请输入搜索关键字

确定