HPL Tubes|Seamless Phosphated HPL Tube

VIEW MORE+

PRODUCTS

NEWS

- What is the Difference between Hastelloy C-276 and C-2000?

- Introduce Titanium Alloy Coiled Tubing

- What is Coiled Tubing?

- Inconel vs Incoloy Nickel Alloy Tube

- Introduce St 37.4 Black Phosphate Hydraulic Seamless Tube

- Inconel vs Hastelloy: Corrosion Resistance & High-Temp Applications

- Monel 400 vs. Stainless Steel: A Guide to Selecting Materials for Corrosive Environments

- Inconel 600 vs 601 vs 625: Nickel-based alloy pipe performance comparison and selection guide

- Difference between Monel 400 and Monel K-500 Tubes

- Classification of Nickel and Nickel Alloy

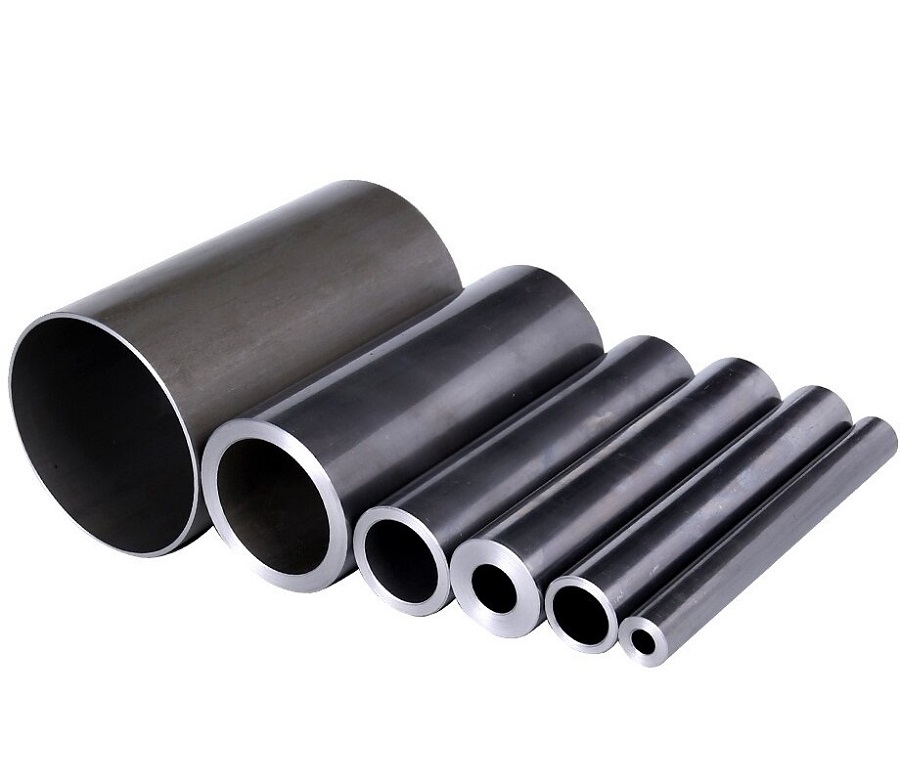

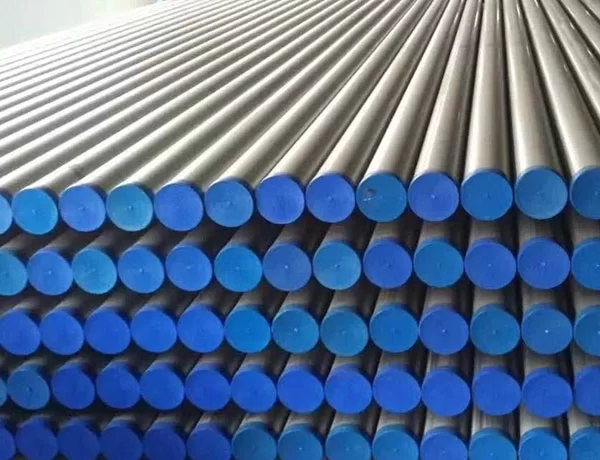

Automotive Steel Tube|Automotive tubing

Automotive steel tubing is one of the essential materials in the automotive manufacturing industry. It is widely used in various types of passenger cars, commercial vehicles, and other automotive systems.

Description

Automotive Steel Tube Description:

Automotive steel tubing is one of the essential materials in the automotive manufacturing industry. It is widely used in various types of passenger cars, commercial vehicles, and other automotive systems including engine systems, gearbox systems, transmission systems, steering systems, chassis systems, and other critical components. These tubing materials play a crucial role in automotive manufacturing, directly impacting the performance, safety, and lifespan of vehicles. Our automotive steel tube boasts excellent performance and stable quality, earning high recognition and favor from domestic and international OEMs as well as high-end aftermarket parts manufacturers.

Automotive Steel Tube Advantages:

1. Excellent Mechanical Performance: Our tubing undergoes precision cold drawing or cold rolling processes, resulting in outstanding mechanical properties suitable for various subsequent processing methods such as cold bending, extrusion, and expansion.

2. High-Quality Surface Finish: The tubing surfaces are smooth and flat, meeting the requirements for various surface treatments including electrophoresis, painting, powder coating, galvanization, and chrome plating, ensuring high-quality appearance.

3. Precision Dimensional Accuracy: We strictly control the outer diameter and wall thickness of the tubing to ensure dimensional precision meeting industry standards and satisfying various customer requirements.

4. Superior Microstructure: Through precision cold processing or cold rolling, the tubing exhibits a uniform and fine microstructure, guaranteeing product stability and reliability.

Automotive Steel Tube Specifications:

- Automotive Steel Tube Size

Product Specifications: Outer Diameter (O.D) 16-245mm, Wall Thickness (WT) 1-32mm.

- Automotive Steel Tube Standards:

- GB/T 3639: Cold-drawn or cold-rolled precision seamless steel tubes.

- DIN 2391: Cold-drawn precision seamless steel tubes.

- DIN 2393: Welded precision steel tubes with special size accuracy.

- EN 10305-1: Technical delivery conditions for precision steel tubes - Part 1: Seamless cold-drawn tubes.

- EN 10305-2: Technical delivery conditions for precision steel tubes - Part 2: Welded cold-drawn tubes.

- ASTM A519: Seamless carbon and alloy steel mechanical tubing.

- ASTM A513: Electric-resistance-welded carbon and alloy steel mechanical tubing.

- JIS G3445: Carbon steel tubes for machine structural purposes.

- JIS G4051: Carbon steel for machine structural use.

- Automotive Steel Tube Steel Grades:

Including but not limited to 10#, 20#, 35#, 45#, 55#, Q355B, 25Mn, 16MnCr5, 20MnCr5, 30CrMo, 35CrMo, 42CrMo, 20Cr, 40Cr, 20CrNiMo; ST37, ST45, ST52, 34CrMo4, 42CrMo4; E235, E255, E355; 1010, 1020, 1026, 1035, 1045, 1050, 4130, 4140, 8620; STKM 11A, STKM 12B, STKM 13C, STKM 14B; S10C, S20C, S35C, S45C, and others.

Automotive Steel Tube Delivery Conditions:

1. Cold worked/hard (+C) (BK): After cold working, the tubing is hardened. This condition is suitable for applications requiring high strength and hardness.

2. Cold worked/soft (+LC) (BKW): After cold working, the tubing is softened. This condition is suitable for applications requiring certain strength and good machinability.

3. Stress relieved after cold working (+SR) (BKS): Stress relief annealing is performed on the tubing after cold working to eliminate residual stresses. This condition is suitable for applications requiring high strength and low residual stress.

4. Annealed (+A) (GBK): The tubing is heated to an appropriate temperature and then slowly cooled to room temperature to achieve softening and improved machinability. This condition is suitable for applications requiring good machinability and toughness.

5. Normalized (+N) (NBK): The tubing is heated to an appropriate temperature and then slowly cooled to achieve normalization (normalization is a heat treatment process that can increase strength and hardness by increasing grain size). This condition is suitable for applications requiring high strength and hardness.

6. Quenched and tempered (QT): The tubing is heated to an appropriate temperature, held for a period of time, then quenched, and finally tempered (tempering is a heat treatment process that can increase toughness while maintaining certain hardness). This condition is suitable for applications requiring high strength, hardness, and toughness.

Automotive steel tube|Automotive steel tubing

Products

-

-

Automotive Steel Tube|Automotive tubing

VIEW MORE+ -

Cold Drawn Hydraulic Tubes|Cold Drawn Galvanized Hydraulic Steel Tube

VIEW MORE+

请输入搜索关键字

确定