HPL Tubes|Seamless Phosphated HPL Tube

VIEW MORE+

PRODUCTS

NEWS

- What is the Difference between Hastelloy C-276 and C-2000?

- Introduce Titanium Alloy Coiled Tubing

- What is Coiled Tubing?

- Inconel vs Incoloy Nickel Alloy Tube

- Introduce St 37.4 Black Phosphate Hydraulic Seamless Tube

- Inconel vs Hastelloy: Corrosion Resistance & High-Temp Applications

- Monel 400 vs. Stainless Steel: A Guide to Selecting Materials for Corrosive Environments

- Inconel 600 vs 601 vs 625: Nickel-based alloy pipe performance comparison and selection guide

- Difference between Monel 400 and Monel K-500 Tubes

- Classification of Nickel and Nickel Alloy

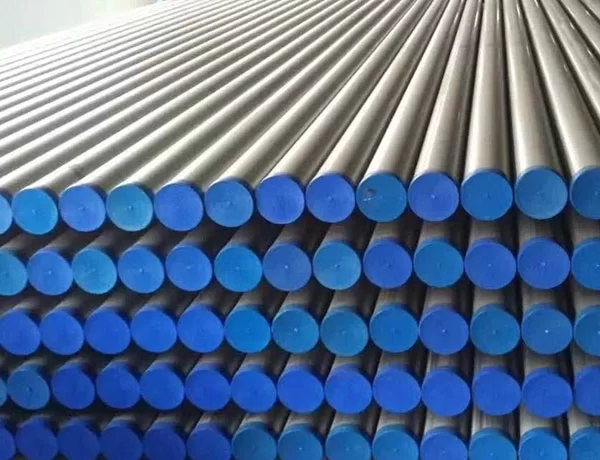

Cold Drawn Hydraulic Tubes|Cold Drawn Galvanized Hydraulic Steel Tube

Cold drawn hydraulic tubes play a crucial role in hydraulic systems across various industries and automotive applications, offering superior dimensional accuracy, surface finish, and mechanical performance.

Description

Cold drawn hydraulic tubes play a crucial role in hydraulic systems across various industries and automotive applications, offering superior dimensional accuracy, surface finish, and mechanical performance.

1. Cold Drawn Hydraulic Tubes Manufacturing Process:

- Material Selection: Typically crafted from materials such as carbon steel, stainless steel, or alloy steel, depending on specific application requirements.

- Initial Tube Preparation: Begin with a tube that has a diameter and wall thickness larger than the final desired specifications.

- Heating: The tube may undergo preheating to improve its plasticity, facilitating the cold drawing process.

- Cold Drawing Process: The tube is pulled through a specially designed die in multiple passes. With each pass, the diameter and wall thickness decrease, while the length increases. This process occurs at room temperature, earning it the name "cold drawing."

2. Cold Drawn Hydraulic Tubes Characteristics and Advantages:

- Dimensional Precision: Cold drawing achieves strict dimensional control, ensuring precise requirements for the diameter, wall thickness, and length of hydraulic tubes.

- Surface Finish: Cold-drawn tubes exhibit a smooth surface, often polished, reducing friction resistance and enhancing the efficiency of hydraulic systems.

- Mechanical Properties: Cold-drawn tubes typically possess superior mechanical properties compared to tubes produced through hot rolling or other methods, including higher strength and hardness.

- Reduced Defects: The cold drawing process minimizes defects both on the internal and external surfaces of the tube, such as internal seams, surface flaws, and uneven wall thickness, thereby enhancing reliability.

3. Cold Drawn Hydraulic Tubes Application Areas:

- Cold drawn hydraulic tubes find widespread use in hydraulic systems, including hydraulic machinery, cylinders, pumps, and more.

- In automotive engineering, these tubes are employed in manufacturing braking systems, transmission systems, and other hydraulic control components.

- Due to their exceptional dimensional accuracy and surface finish, cold drawn hydraulic tubes are also utilized in industrial applications requiring high-precision tubing.

4. Cold Drawn Hydraulic Tubes Advantages and Applicability:

- The cold drawing process produces tubes with high precision and consistency, making them suitable for applications with strict dimensional requirements.

- Thanks to their smooth surface and improved mechanical properties, cold drawn hydraulic tubes excel in high-pressure hydraulic systems.

Cold Drawn Hydraulic Tubes

Products

-

-

Automotive Steel Tube|Automotive tubing

VIEW MORE+ -

Cold Drawn Hydraulic Tubes|Cold Drawn Galvanized Hydraulic Steel Tube

VIEW MORE+

请输入搜索关键字

确定