Stainless Steel Tubes for Hydraulic Instrumentation

VIEW MORE+- What is the Difference between Hastelloy C-276 and C-2000?

- Introduce Titanium Alloy Coiled Tubing

- What is Coiled Tubing?

- Inconel vs Incoloy Nickel Alloy Tube

- Introduce St 37.4 Black Phosphate Hydraulic Seamless Tube

- Inconel vs Hastelloy: Corrosion Resistance & High-Temp Applications

- Monel 400 vs. Stainless Steel: A Guide to Selecting Materials for Corrosive Environments

- Inconel 600 vs 601 vs 625: Nickel-based alloy pipe performance comparison and selection guide

- Difference between Monel 400 and Monel K-500 Tubes

- Classification of Nickel and Nickel Alloy

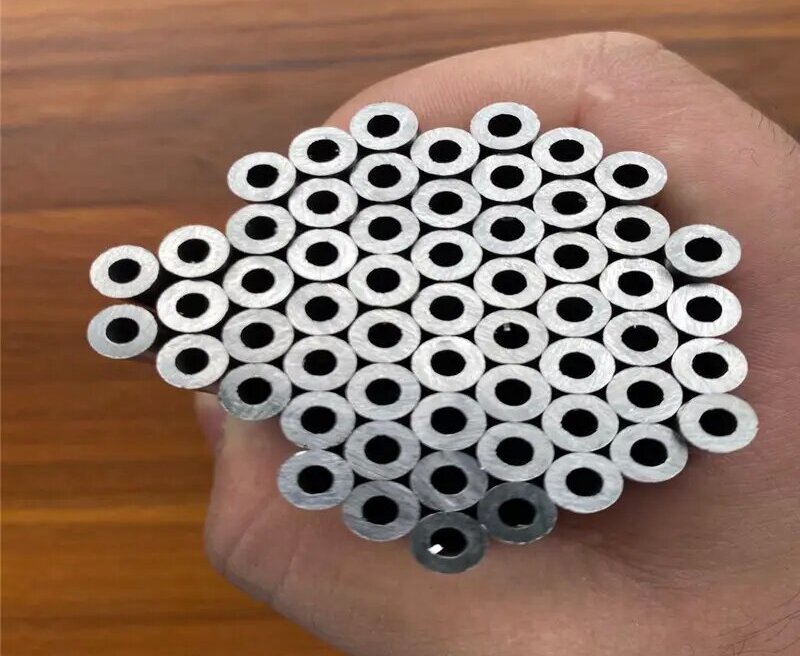

Electropolished Stainless Steel Tube|EP Tube

What is electropolished stainless steel tube? Electropolishing is an electrochemical finishing process that removes a thin layer of material from the stainless tube.The process leaves a shiny, smooth, ultra-clean surface finish.

What is electropolished stainless steel tube?

Electropolished stainless steel tube is a type of stainless steel tubing that has undergone an electropolishing process to enhance its surface finish and cleanliness. This process involves immersing the tube in an electrolyte bath and applying a current, which removes a thin layer of material from the surface, resulting in a smooth, shiny, and ultra-clean surface. Electropolished stainless steel tubes are highly valued in industries requiring stringent sanitary conditions and corrosion resistance, such as pharmaceuticals, food and beverage processing, and semiconductor manufacturing, due to their improved microfinish, reduced surface roughness, and enhanced passivation layer.

Electropolished Stainless Steel Tube Specifications:

1. Specifications: The electropolished tube adheres meticulously to the stringent standards of ASTM A213 and ASTM A269, guaranteeing structural integrity and unwavering performance.

2. Clean Room Standards: Compliant with ISO14644-1 Class 5 clean room standards, these tubes uphold an environment of utmost cleanliness, which is pivotal for sensitive applications.

3. Size: The tubes dimensions, offer versatility to cater to various application requirements.

|

NPS |

OD (mm) |

WT (mm) |

|

1/4" |

6.35 |

0.89 |

|

3/8" |

9.53 |

1 |

|

3/8" |

9.53 |

0.89 |

|

1/2" |

12.7 |

1.65 |

|

3/4" |

19.05 |

1.65 |

|

3/4" |

19.05 |

2.11 |

|

1" |

25.4 |

1.65 |

|

1" |

25.4 |

2.11 |

|

1 1/4" |

31.75 |

1 |

|

1 1/4" |

31.75 |

1.65 |

|

1 1/2" |

38.1 |

1.65 |

|

2" |

50.8 |

1.65 |

|

10A |

17.3 |

1.2 |

|

15A |

21.7 |

1.65 |

|

20A |

27.2 |

1.65 |

|

25A |

34 |

1.65 |

|

32A |

42.7 |

1.65 |

|

40A |

48.6 |

1.65 |

4. Surface Characteristics: Controlled roughness and hardness parameters on the tubes surface strike an optimal balance between functionality and aesthetics.

5. Manufacturing Process: The journey of creating these tubes encompasses cold rolling, cold drawing, annealing, and the pivotal electropolishing process. Each step contributes to the exceptional attributes of the final product.

6. Material Grade: Crafted from the resilient stainless steel grades 304/304L; 316/316L; 1.4301/1.4307; 1.4404/1.4435, these tubes exhibit corrosion resistance, durability, and adaptability to diverse environments.

Electropolished Stainless Steel Tube Packaging:

The packaging of these tubes reflects a commitment to precision and protection:

- Each tube undergoes a thorough N2 gas purging process to eliminate any residual contaminants.

- Both ends are securely capped to ensure zero ingress of potential pollutants.

- The tubes are meticulously sealed within dual-layered clean bags, preserving their immaculate condition.

- The final safeguard involves housing the tubes in a robust wooden case, guaranteeing their safe transit and storage, loading... [600x300].

Electropolished Stainless Steel Tube Clean Room Standards:

Even within the confines of clean room environments, the electropolished tube stands as a beacon of excellence:

- The tubes presence within ISO14644-1 Class 5 clean room standards underscores its role in maintaining the highest levels of sterility and cleanliness.

- Versatility Across Applications:

Electropolished Stainless Steel Tube Roughness & Hardness

|

Production Standard |

Internal Roughness |

External Roughness |

Hardness Max |

|

HRB |

|||

|

ASTM A269 |

Ra≤0.25μm |

Ra≤0.5μm |

90 |

Electropolished Stainless Steel Tube Process

The electropolishing process for stainless steel tubes involves immersing cleaned tubes in an electrolyte bath while applying a direct current, causing metal ions to dissolve from the surface, resulting in a smoother finish. Parameters such as current density and duration are controlled to achieve the desired surface quality, followed by thorough rinsing and possibly a passivation treatment for enhanced corrosion resistance. Inspection ensures the tubes meet quality standards before being packaged for use in industries requiring high cleanliness and corrosion resistance, such as pharmaceuticals and food processing.

The electropolished stainless tube applications:

- Semiconductor and Display Technologies: These tubes facilitate the precision demanded by semiconductor and display manufacturing processes.

- Food, Pharmaceutical, and Bioproduction Equipment: In industries driven by purity, electropolished tubes provide a conduit that upholds the integrity of critical materials.

- Ultra-Pure Clean Pipelines: The tubes excel in scenarios that require contamination-free transportation, guaranteeing the purity of fluids and gases.

- Solar Energy Equipment: They play an integral role in the creation of premium solar energy equipment, ensuring longevity and efficiency.

- Shipbuilding Engine Pipelines: In maritime contexts, electropolished tubes offer corrosion resistance and durability for engine pipelines.

- Aerospace Engines: These tubes find their place in aerospace applications, contributing to the reliability and efficiency of engines.

- Hydraulic and Mechanical Systems: Precision surfaces augment the efficiency and lifespan of hydraulic and mechanical systems.

- Clean Gas Transportation: The tubes serve as reliable conduits for the secure and uncontaminated transportation of gases.

- Biotechnology: The impeccably smooth and clean surfaces of these tubes are ideal for biotechnology applications. They minimize contamination risks and facilitate the seamless transfer of fluids in intricate biological processes.

- Semiconductor Manufacturing: Precision and purity are paramount in semiconductor fabrication. Electropolished tubes contribute to creating the pristine environments required for semiconductor manufacturing.

- Pharmaceuticals: In the pharmaceutical realm, where purity and sterility are non-negotiable, electropolished tubes provide a conduit that ensures the untainted transportation of crucial materials.

Electropolished Stainless Steel Tube

-

-

Small-Diameter Heavy-Wall Tube|Heavy-Wall Tubing

VIEW MORE+ -

Super Austenitic 904L tubes|Super Austenitic 904L precision tubes

VIEW MORE+

请输入搜索关键字

确定