Inconel vs Incoloy Nickel Alloy Tube

Nickel-based alloys are a type of high-performance alloy that has nickel as its main component as well as additional elements like chromium, iron, molybdenum, and aluminum. They are commonly utilized in high-temperature, high-pressure, and corrosive conditions. These alloys are widely used in the aerospace, chemical, marine engineering, and energy industries due to their outstanding corrosion resistance, oxidation resistance, and high-temperature strength.

Inconel and Incoloy are two typical nickel-based alloys, each having their own set of properties and applications.

Comparison of Inconel Alloy and Incoloy Alloy

1. Chemical Composition

The material matrix differs between Inconel alloy and Incoloy alloy:

- Inconel alloy: a nickel-chromium alloy; high Ni+Cr+Mo

- Incoloy alloy: an iron-nickel alloy; mostly nickel and iron-based, with much higher iron content.

Core Element Content Comparison

|

Core Element Content |

Inconel |

Incoloy |

|

Nickel (Ni) |

58%-72% |

30%-46% |

|

Iron (Fe) |

≤15% |

22%-45% |

|

Chromium (Cr) |

14%-23% |

19%-23% |

|

Molybdenum (Mo) |

8%-10% |

2%-3.5% |

2. Mechanical Properties

|

Performance indicators |

Inconel |

Incoloy |

|

Tensile Strength (at Room Temp.) |

900-1300 MPa |

600-800 MPa |

|

Yield Strength (at High Temp.) |

Excelent |

Medium |

|

Hardness |

200-350 HB |

150-220 HB |

3. Main Perfomances

High temperature performance

Inconel:

- Extremely high temperature oxidation resistance

- Extremely strong creep deformation resistance

Incoloy:

- Good economic performance in medium and high temperature environments

- Medium creep deformation resistance, iron base is easy to soften at high temperatures

Corrosion resistance

Inconel:

- Excellent resistance to pitting/crevice corrosion

- Strong resistance to oxidizing acids

Incoloy:

- Strong resistance to reducing acids

- General corrosion resistance

Processing and welding performance

Inconel:

- Easy to work harden, difficult to cold work

- Solution annealing is required after welding to remove stress

Incoloy:

- Iron base has better ductility and good cutting performance

- No need for post-weld treatment

4. Applications

Applicable temperature

- Inconel: >1000℃

- Incoloy: 600-900℃

Applicable media

- Inconel: high Cl⁻ solution; concentrated nitric acid, chromic acid (reducing acid)

- Incoloy: sulfide corrosion medium, phosphoric acid (oxidizing acid)

Applicable industries

- Inconel: aerospace, nuclear energy, marine engineering

- Incoloy: oil and gas, chemical manufacturing, electricity and energy

5. Cost

Incoloy alloy is more dominant:

- Incoloy alloy contains extra iron components to replace some of the nickel elements, making it more cost-effective.

6. Service life

Inconel alloy is more predominant:

- Inconel alloy has a greater nickel alloy concentration and is more corrosion resistant in harsh conditions.

Why is Incoloy alloy less suitable for extremely high temperatures than Inconel alloy?

1. Low high temperature strength

Metal materials mechanical properties under extreme conditions differ from those at normal temperature, resulting in plastic deformation and fracture aging concerns. As the service temperature and stress levels rise, the creep issue will become more apparent. As a result, creep performance is a significant indicator for evaluating metals service life in high temperature environments. Incoloy alloy has a larger iron concentration than Inconel alloy, which reduces its creep strength and endurance strength in high temperature environments.

Increasing the amount of iron in an alloy reduces its creep strength, because:

- Its weak solid solution strengthening action, resulting in decreased matrix strength at higher temperatures.

- At high temperatures, alloys with a high iron content are more likely to generate coarse grain boundaries, increasing the likelihood of grain boundary sliding and aggravating creep deformation.

- When the iron concentration is high, it will enhance the precipitation of particular brittle phases in the alloy, making the material more brittle at high temperatures, causing creep failure.

2. Limited high temperature oxidation resistance and corrosion resistance

Iron oxidizes at a quicker rate than Nickel. Incoloy alloy is susceptible to oxidation in extremely high temperature settings, and its oxidation resistance is inferior to that of Inconel alloy.

Incoloy operates well in high temperature conditions (600-900℃).

⭐Our Capacity

Available Nickel Alloy Grade:

- Inconel: Inconel 600, Inconel 601, Inconel 625

- Incoloy: Incoloy 800, Incoloy 800H & 800HT, Incoloy 825

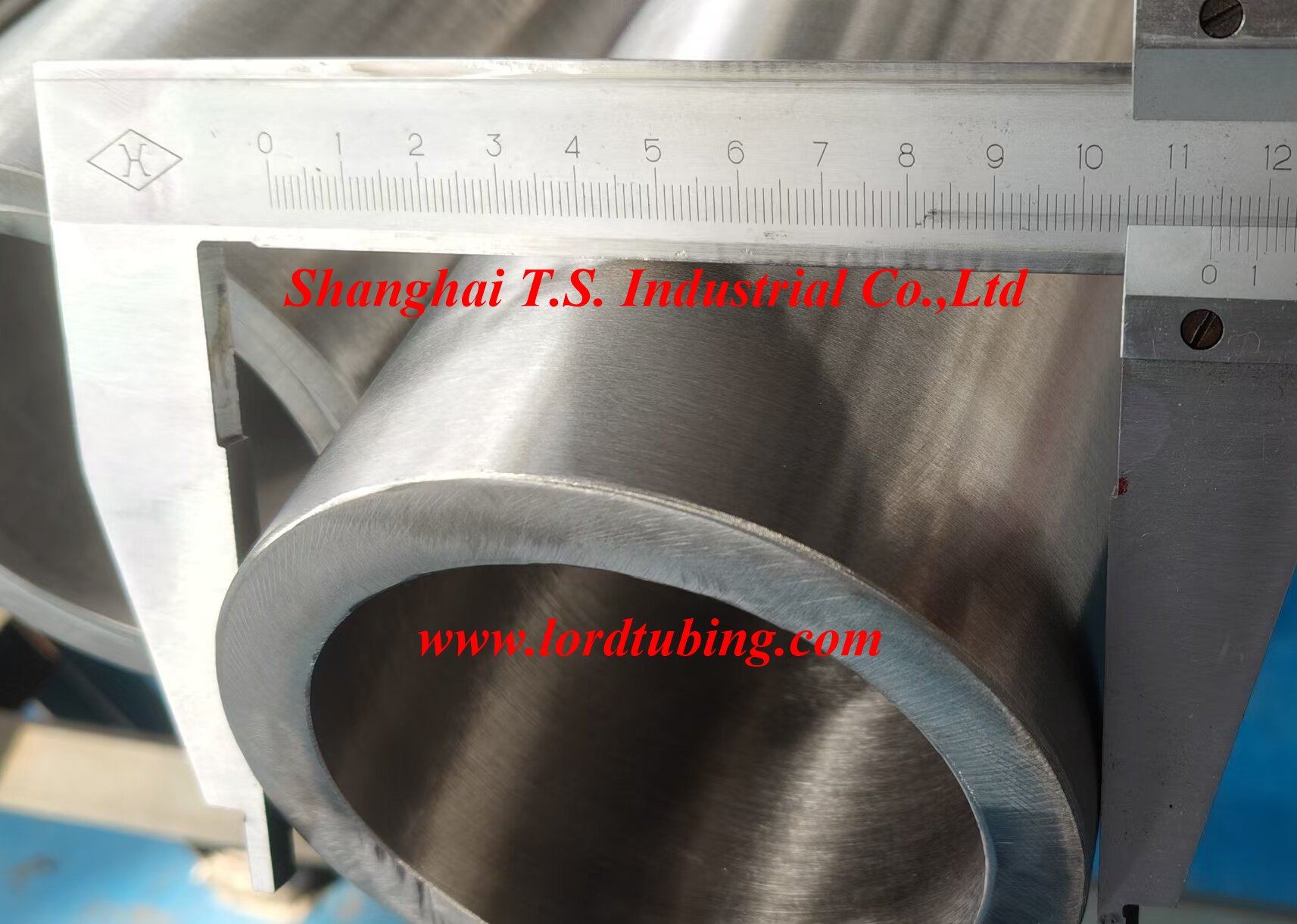

Available Size of Our Nickel Alloy Tube

- OD: 4.5mm-219.1mm

- WT: 1mm-20mm

- Length: ≤12metres

Inconel vs Incoloy Nickel Alloy Tube

请输入搜索关键字

确定