What is the Difference between Hastelloy C-276 and C-2000?

Hastelloy C is not a specific standardized grade but refers to a family of nickel-based high-corrosion-resistant alloys, primarily designed for highly corrosive environments in industries such as chemical processing, environmental protection, and pharmaceuticals. Common commercially available grades in the Hastelloy C series include Hastelloy C-276, C-2000, and C-22.

- Flue gas desulfurization (FGD) systems

- Chemical reactors and heat exchangers

- Pharmaceutical purified water systems

- Paper industry bleaching towers

- Acidic wastewater treatment systems

- Seawater cooling systems and marine engineering equipment

- Electroplating and hydrometallurgical industries

|

Element |

B622 N10276 |

B622 N06200 |

|

Ni |

Balance |

Balance |

|

Cr |

14.50-16.50 |

22.00-24.00 |

|

Mo |

15.00-17.00 |

15.00-17.00 |

|

Fe |

4.00-7.00 |

≤3.00 |

|

W |

3.00-4.50 |

- |

|

C |

≤0.01 |

≤0.01 |

|

Si |

≤0.08 |

≤0.08 |

|

Co |

≤2.50 |

≤2.00 |

|

Mn |

≤1.00 |

≤0.50 |

|

V |

≤0.35 |

- |

|

P |

≤0.040 |

≤0.025 |

|

S |

≤0.030 |

≤0.010 |

|

Cu |

- |

1.30-1.90 |

|

Al |

- |

≤0.50 |

|

Grade |

Tensile Strength, ksi [MPa] |

Yield Strength, ksi [MPa] |

Elongation in 2 in./4D |

Hardness |

|

B622 N10276 |

≥100 [690] |

≥41 [283] |

≥40 |

90-100 HRB |

|

B622 N06200 |

≥100 [690] |

≥45 [310] |

≥45 |

80-90 HRB |

|

Density |

8.89 g/cm³ |

8.5 g/cm³ |

|

Melting Range |

1325–1370°C |

1328-1358°C |

|

Specific Heat Capacity |

407 J/kg·°C |

428 J/kg·°C |

|

Elasticity Modulus |

208 GPa |

206 GPa |

|

Thermal Conductivity |

10.2 W/(m·K) |

10.8 W/(m·K) |

|

Coefficient of Thermal Expansion |

11.2 μm/m·°C |

12.4 μm/m·°C |

- Exceptional resistance to chloride stress corrosion cracking (SCC)

- Superior resistance to sulfides, oxidizing acids, and reducing acids.

- Outstanding resistance to sulfuric acid, chlorides, and chloride salts

- Sulfuric acid storage and transportation equipment

- Chloride gas treatment systems.

- High-temperature/pressure petroleum refining processes

- Reactors in chloride-rich environments

- Marine engineering equipment.

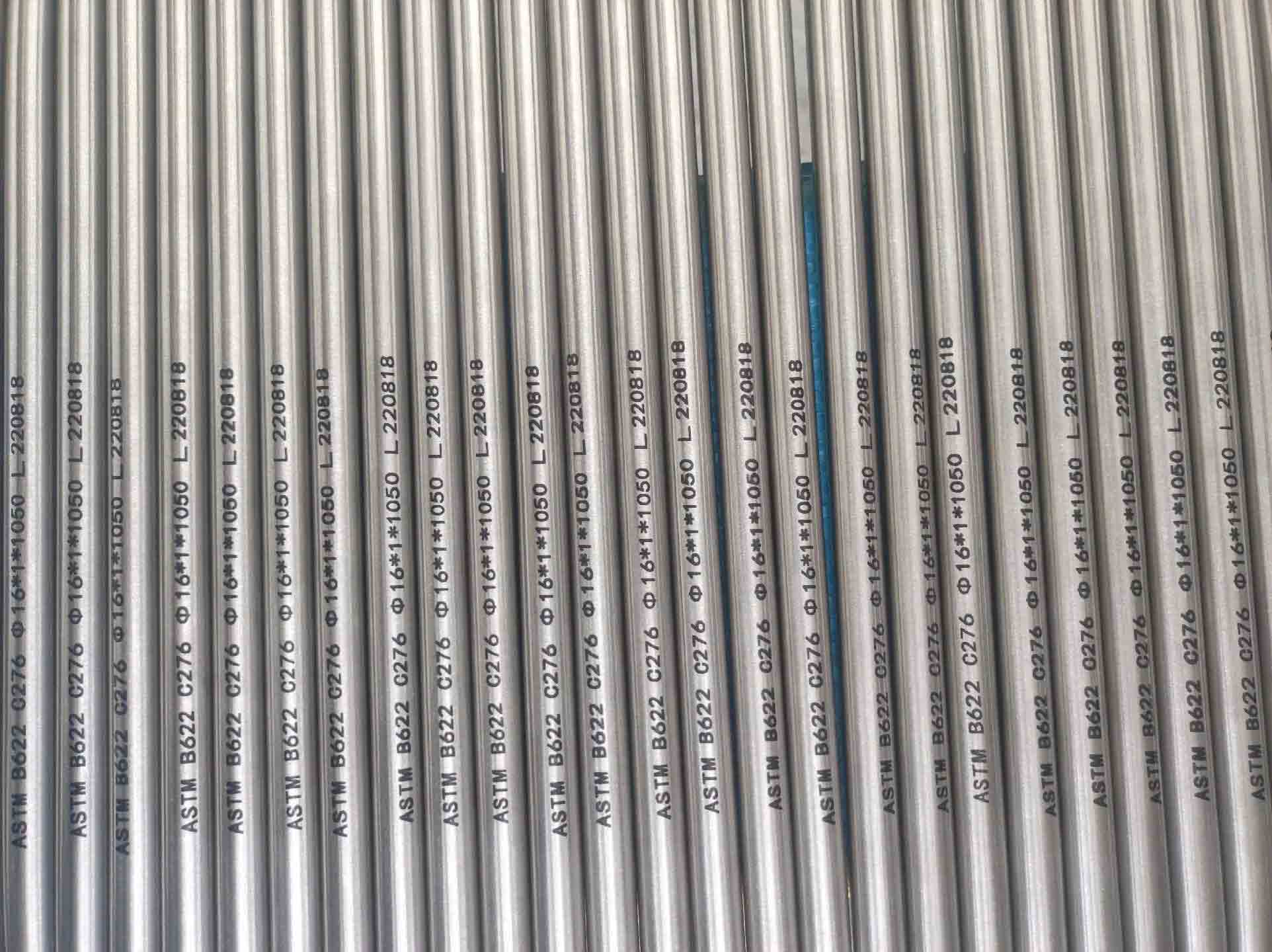

If you are interested in nickel alloy seamless tubes Hastelloy C-276 and C-2000, welcome to contact us.

Hastelloy C-276 vs C-2000 Tube

请输入搜索关键字

确定