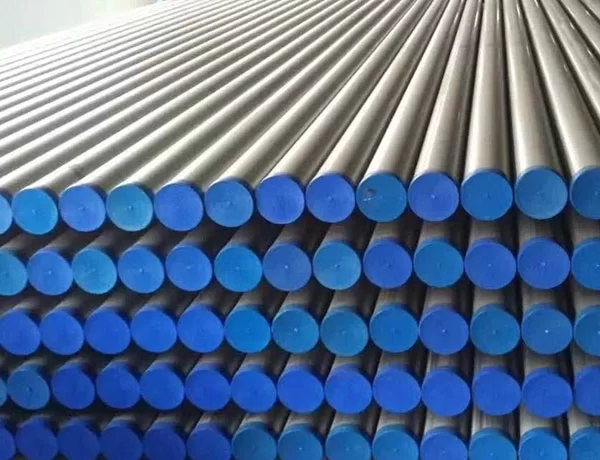

HPL Tubes|Seamless Phosphated HPL Tube

VIEW MORE+- What is the Difference between Hastelloy C-276 and C-2000?

- Introduce Titanium Alloy Coiled Tubing

- What is Coiled Tubing?

- Inconel vs Incoloy Nickel Alloy Tube

- Introduce St 37.4 Black Phosphate Hydraulic Seamless Tube

- Inconel vs Hastelloy: Corrosion Resistance & High-Temp Applications

- Monel 400 vs. Stainless Steel: A Guide to Selecting Materials for Corrosive Environments

- Inconel 600 vs 601 vs 625: Nickel-based alloy pipe performance comparison and selection guide

- Difference between Monel 400 and Monel K-500 Tubes

- Classification of Nickel and Nickel Alloy

DIN 2391 Hydraulic Steel Tube

DIN 2391 is a standard for seamless precision steel tubes used in hydraulic and pneumatic systems, which ensures that the seamless precision steel tubes meet certain criteria requirement.

What is DIN 2391 hydraulic steel tube?

DIN 2391 is a standard for seamless precision steel tubes used in hydraulic and pneumatic systems, which ensures that the seamless precision steel tubes meet certain criteria requirement.

DIN 2391 Hydraulic Steel Tube Definition:

DIN 2391 specifies the technical delivery conditions for seamless precision steel tubes suitable for hydraulic and pneumatic systems. These tubes are characterized by their precision dimensions and excellent surface quality.

DIN 2391 Hydraulic Steel Tube Material Grade:

The material used in DIN 2391 hydraulic steel tubes is typically low carbon steel or mild steel, such as St35, St45, or St52. These grades provide good mechanical properties and weldability while maintaining high precision.

DIN 2391 Hydraulic Steel Tube Chemical Composition and Mechanical Property:

The chemical composition of the material depends on the specific grade used. However, in general, the steel used in DIN 2391 hydraulic steel tubes has low carbon content, typically around 0.17% to 0.25%. It may also contain small amounts of other elements such as manganese, phosphorus, sulfur, and silicon.

The mechanical properties of DIN 2391 hydraulic steel tubes are determined by the material grade. The tubes typically exhibit good tensile strength, yield strength, and elongation properties. The exact mechanical properties vary depending on the specific grade and heat treatment.

|

Material Grade |

Chemical Composition |

Mechanical Properties |

|

St35 |

C: 0.17-0.22% |

Tensile Strength: ≥ 340 MPa |

|

Mn: 0.35% max |

Yield Strength: ≥ 235 MPa |

|

|

P: 0.025% max |

Elongation: ≥ 25% |

|

|

S: 0.025% max |

|

|

|

St45 |

C: 0.21-0.25% |

Tensile Strength: ≥ 410 MPa |

|

Mn: 0.40-0.80% |

Yield Strength: ≥ 255 MPa |

|

|

P: 0.025% max |

Elongation: ≥ 21% |

|

|

S: 0.025% max |

|

|

|

St52 |

C: 0.22% max |

Tensile Strength: ≥ 500 MPa |

|

Mn: 1.60% max |

Yield Strength: ≥ 355 MPa |

|

|

P: 0.025% max |

Elongation: ≥ 21% |

|

|

S: 0.025% max |

|

DIN 2391 Hydraulic Steel Tube Delivery Condition:

DIN 2391 hydraulic steel tubes are usually supplied in the cold drawn or cold rolled condition. This ensures the precise dimensions and excellent surface quality required for hydraulic and pneumatic applications. The tubes may undergo subsequent heat treatment processes if necessary.

|

Designation |

Symbol |

Description |

|

Cold finished (hard) |

BK(+C) |

|

|

Cold finished (Soft) |

BKW |

|

|

Cold finished and stress-relieved |

BKS(+SR) |

|

|

Annealed |

GBK(+A) |

The last Cold forming process is followed by annealing in a controlled atmosphere. |

|

Normalized |

NBK(+N) |

The last cold forming process is followed by annealing above the upper transformation point in a controlled atmosphere. |

DIN 2391 Hydraulic Steel Tube Permissible Variations in Dimensions:

DIN 2391 specifies permissible variations in dimensions to ensure the desired precision. These variations include tolerances for outside diameter, wall thickness, length, straightness, and ovality. These strict tolerances guarantee the reliable and efficient functioning of hydraulic systems.

DIN 2391 Hydraulic Steel Tube Surface Treatments:

Surface treatments is to enhance their properties and improve their resistance to corrosion. The specific surface treatment applied to these tubes depends on the intended application and the environmental conditions they will be exposed to. Here are some common surface treatment options for DIN 2391 hydraulic steel tubes:

(1). Phosphating: Phosphating is a surface treatment process that involves the deposition of a phosphate coating on the steel surface. It provides corrosion resistance and improves the adhesion of subsequent coatings, such as paint or powder coating.

(2). Galvanizing: Galvanizing is a process where a layer of zinc is applied to the surface of the steel tube. This zinc coating acts as a barrier against corrosion, protecting the underlying steel. Galvanized hydraulic steel tubes are commonly used in outdoor and corrosive environments.

(3). Electroplating: Electroplating involves the deposition of a layer of metal, such as chrome or nickel, onto the surface of the steel tube. This process provides enhanced corrosion resistance, improved aesthetics, and can also offer increased hardness and wear resistance.

(4). Epoxy Coating: Epoxy coatings are often applied to hydraulic steel tubes to provide a protective barrier against corrosion. Epoxy coatings are chemically resistant, provide good adhesion to the substrate, and offer excellent corrosion protection in various environments.

(5). Powder Coating: Powder coating is a process where a dry powder is electrostatically applied to the surface of the steel tube and then cured under heat. This creates a durable and uniform coating that offers excellent resistance to corrosion, abrasion, and chemicals. Powder coating also provides an attractive finish and can be customized in terms of color and texture.

(6). Passivation: Passivation is a chemical treatment that removes free iron and other contaminants from the surface of the steel tube, improving its corrosion resistance. It typically involves the use of acids or other chemical solutions to clean and neutralize the surface.

The choice of surface treatment depends on factors such as the application requirements, environmental conditions, and the desired aesthetics. It is essential to select the appropriate surface treatment method and consult the relevant standards and specifications to ensure the desired performance and longevity of DIN 2391 hydraulic steel tubes.

DIN 2391 Hydraulic Steel Tube Advantages:

1. Precision: DIN 2391 hydraulic steel tubes are manufactured with high precision, ensuring consistent dimensions and excellent surface finish.

2. Strength and Durability: The material used in these tubes offers good mechanical properties, making them strong and durable.

3. Seamless Construction: Being seamless, these tubes have no welded joints, which eliminates the risk of leakage or weak points.

4. Corrosion Resistance: DIN 2391 hydraulic steel tubes can be coated or treated to enhance their resistance to corrosion, extending their lifespan.

5. Versatility: These tubes are suitable for a wide range of hydraulic and pneumatic applications, including fluid transfer, power steering systems, and hydraulic cylinders.

DIN 2391 Hydraulic Steel Tube Applications:

1. Hydraulic and Pneumatic Systems: These tubes are widely used for hydraulic and pneumatic applications, such as fluid power systems, actuators, and cylinders.

2. Automotive Industry: They are employed in automotive applications like power steering systems, brake systems, and suspension components.

3. Machinery and Equipment: DIN 2391 tubes are used in the construction of machinery and equipment where precise hydraulic control is required.

4. Oil and Gas Industry: They can be utilized in hydraulic systems for oil and gas exploration, production, and transportation.

DIN 2391 Hydraulic Steel Tube

- PREV:EN 10305-4 Hydraulic Steel Tube

- NEXT:NO DATA

-

-

Automotive Steel Tube|Automotive tubing

VIEW MORE+ -

Cold Drawn Hydraulic Tubes|Cold Drawn Galvanized Hydraulic Steel Tube

VIEW MORE+

请输入搜索关键字

确定