HPL Tubes|Seamless Phosphated HPL Tube

VIEW MORE+

PRODUCTS

NEWS

- What is the Difference between Hastelloy C-276 and C-2000?

- Introduce Titanium Alloy Coiled Tubing

- What is Coiled Tubing?

- Inconel vs Incoloy Nickel Alloy Tube

- Introduce St 37.4 Black Phosphate Hydraulic Seamless Tube

- Inconel vs Hastelloy: Corrosion Resistance & High-Temp Applications

- Monel 400 vs. Stainless Steel: A Guide to Selecting Materials for Corrosive Environments

- Inconel 600 vs 601 vs 625: Nickel-based alloy pipe performance comparison and selection guide

- Difference between Monel 400 and Monel K-500 Tubes

- Classification of Nickel and Nickel Alloy

HPL Tubes|Seamless Phosphated HPL Tube

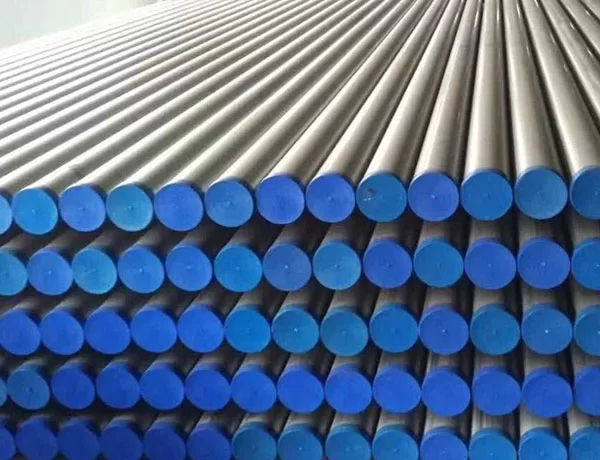

HPL tubes are seamless cold-drawn precision steel tubes predominantly used as pressure lines in hydraulically or pneumatically operated equipment.

Description

What are HPL Tubes?

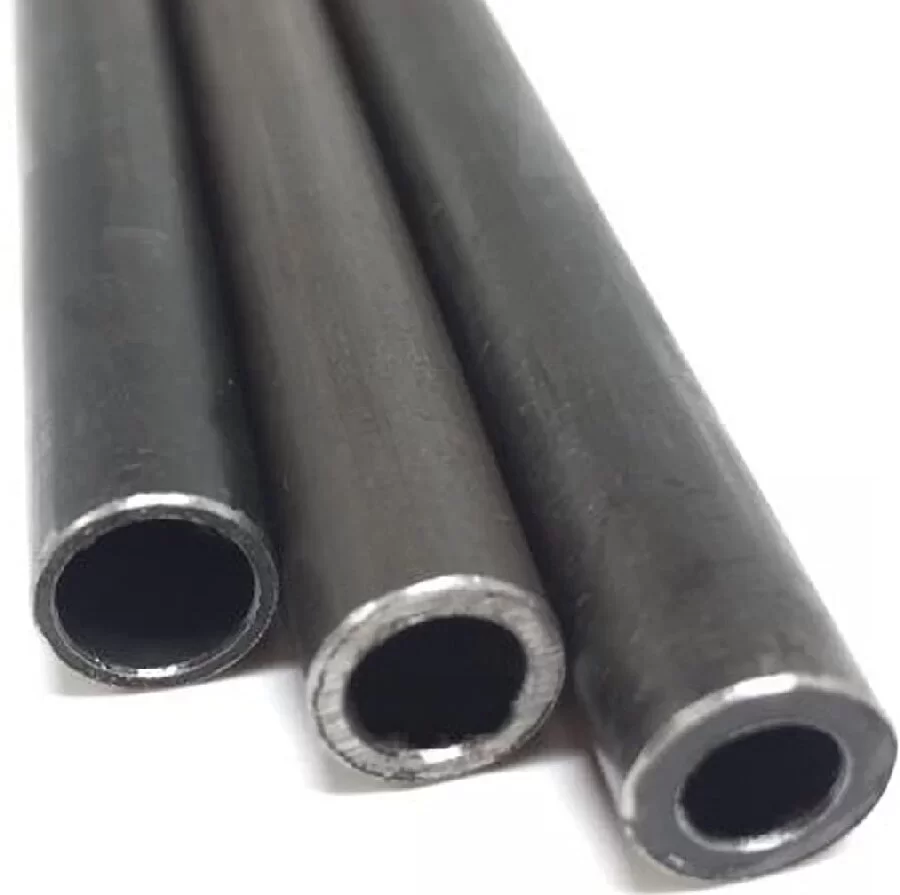

HPL Tubes are seamless, cold-drawn precision steel tubes primarily utilized as pressure lines in hydraulic or pneumatic systems. They can be connected using both detachable and non-detachable fittings. These tubes must withstand velocity and pressure changes, leading to pressure surges superimposed on the static internal pressure during operation.

HPL Tubes Dimensions

- Outside Diameter: 4 - 120 mm*

- Wall Thickness: 1.0 - 12.5 mm

- Standard Length: 6 m +10/-0 mm (Other dimensions available upon request)

- *Dimensions and deviation limits:

- For OD 4 mm ≤ OD ≤ 80 mm: DIN EN 10305-4

- For OD > 80 mm: DIN EN 10305-1 Table 5

HPL Tubes Deviation Limits

- Adheres to detailed delivery program specifications for outside and inside diameter dimensions and tolerances.

- Straightness in accordance with EN 10305-4.

- Maximum permissible eccentricity for tubes ordered by outside diameter and inside diameter is 7.5%.

- Standard length of 6,000 mm -0/+10 mm, with shorter lengths down to 4,000 mm bundled separately.

HPL Tubes Standard & Materials

- Steel grades: E 235 or E 355 as per EN 10305-4.

- Chemical Composition (maximum values):

- E235: C 0.17%, Si 0.35%, Mn 1.20%, P 0.025%, S 0.015%

- E355: C 0.22%, Si 0.55%, Mn 1.60%, P 0.025%, S 0.015%

- Minimum aluminum content regulated, with allowances for nitrogen-binding elements (Nb, Ti, V).

|

Steel Grade |

C % |

Si % |

Mn % |

P % |

S % |

|

E235 |

≤ 0.17 |

≤ 0.35 |

≤ 1.20 |

≤ 0.025 |

≤ 0.015 |

|

E355 |

≤ 0.22 |

≤ 0.55 |

≤ 1.60 |

≤ 0.025 |

≤ 0.015 |

HPL Tubes Mechanical Properties at Room Temperature

- E235:

- Tensile Strength (Rm): 340 - 480 MPa

- Yield Strength (ReH): 235 MPa

- Elongation (A): 25%

- E355:

- Tensile Strength (Rm): 490 - 630 MPa

- Yield Strength (ReH): 355 MPa

- Elongation (A): 22%

- For OD ≤ 30 mm and wall thickness ≤ 3 mm, ReH minimum values are 10 MPa lower.

|

Steel Grade |

Tensile Strength Rm (MPa) |

Yield Strength ReH (MPa) |

Elongation A % (min) |

|

E235 |

340 - 480 |

235 |

25 |

|

E355 |

490 - 630 |

355 |

22 |

HPL Tubes Workability

- Cold Workability: Suitable for cold working due to final heat treatment. Bending causes a decrease in wall thickness and out-of-roundness. Reduction factors for bends and non-circular cross-sections are given in DIN 2413 Part 2.

- Weldability: Tubes can be welded without preheating using standard welding techniques.

HPL Tubes Surface Conditions & Protection

- Technical Delivery Conditions: Tubes are normalized (+N) in a controlled atmosphere according to EN 10305-4.

- Surface Condition: Smooth inside and outside surfaces with roughness Ra ≤ 4 μm as per EN 10305-4.

- Passivation: Externally galvanized with a zinc coating (12 to 15 μm) plus a passivation layer. Cr(VI)-free coating complies with Directive 2000/53/EG.

- Resistance to Corrosion: White rust resistance ≥ 300 h for OD < 20 mm, ≥ 200 h for OD ≥ 20 mm (ISO 9227). Red rust resistance ≥ 400 hours for all dimensions.

- Temporary Corrosion Protection: Inhibitor-containing mineral oil coating:

- Black tubes: oil-coated internally and externally.

- Galvanized tubes: non-greased or oiled depending on dimensions.

HPL Tubes Tube Ends

- Standard: Smooth un-machined.

- Exception: Pinched off ends for tubes with OD < 8 mm or ID ≤ 4 mm.

- End Seal: Plastic end caps for ID ≤ 4 mm, plastic plugs for ID > 4 mm. Tubes ≤ 42 mm OD and non-standard lengths have open ends protected with blue plastic bags.

HPL Tubes Testing and Inspection

- Testing: Conducted as per DIN EN 10305-4. Additional inspections can be arranged.

- Inspection Certificates: Supplied with a 3.1 inspection certificate as per EN 10204. A 3.2 inspection certificate is available upon request.

HPL Tubes Marking

- Continuous full-length marking including:

- Manufacturers mark

- Tube type

- Dimensions

- Delivery standard

- Steel grade

- Delivery condition

- Batch number

- Additional information

- Country of Origin

- Example: Lordtubing HPL 15 x 11 x 2 EN 10305-4 E235 +N 3484711 Cr6-free MADE IN CHINA

HPL Tubes Packaging

- Tubes ≥ 15 mm OD: Packed in steel-strapped hexagonal bundles.

- Short Lengths & Tubes < 15 mm OD: Supplied in round bundles.

- Custom Packaging: Crates, cardboard tubes, or bundles with foil available by agreement. Crate packing recommended for thin-walled tubes and overseas shipments.

Seamless Phosphated HPL Tube

- PREV::NO DATA

- NEXT:Automotive Steel Tube|Automotive tubing

Products

-

-

Automotive Steel Tube|Automotive tubing

VIEW MORE+ -

Cold Drawn Hydraulic Tubes|Cold Drawn Galvanized Hydraulic Steel Tube

VIEW MORE+

请输入搜索关键字

确定