High Pressure Tubing|High-pressure Hard Tubing

VIEW MORE+- What is the Difference between Hastelloy C-276 and C-2000?

- Introduce Titanium Alloy Coiled Tubing

- What is Coiled Tubing?

- Inconel vs Incoloy Nickel Alloy Tube

- Introduce St 37.4 Black Phosphate Hydraulic Seamless Tube

- Inconel vs Hastelloy: Corrosion Resistance & High-Temp Applications

- Monel 400 vs. Stainless Steel: A Guide to Selecting Materials for Corrosive Environments

- Inconel 600 vs 601 vs 625: Nickel-based alloy pipe performance comparison and selection guide

- Difference between Monel 400 and Monel K-500 Tubes

- Classification of Nickel and Nickel Alloy

Cut-to-Length Steel Tubing

Cut-to-length steel tubing refers to steel tubes that are cut to specific lengths according to customer requirements. This process involves taking longer steel tubes and cutting them into shorter pieces to meet the desired specifications.

What is cut-to-length steel tubing?

Cut-to-length steel tubing refers to steel tubes that are cut to specific lengths according to customer requirements. This process involves taking longer steel tubes and cutting them into shorter pieces to meet the desired specifications. These tubes are precisely cut from longer lengths of tubing stock to meet the exact dimensions needed for various applications.

How and Whats the Process to Cut Steel Tubing to Length

1. Measurement and Marking:

The first step involves measuring and marking the desired length on the steel tubing using measuring tapes, rulers, and markers. Precision is crucial to ensure accuracy in the final product.

2. Cutting Methods:

Saw Cutting:

Tubes are cut using band saws, circular saws, or abrasive saws. The type of saw used depends on the material and thickness of the tubing.

Laser Cutting:

A high-powered laser beam is used to cut the tubing. This method provides high precision and a clean cut, ideal for complex shapes and tight tolerances.

Plasma Cutting:

An accelerated jet of hot plasma is used to cut the tubing. Its suitable for thicker materials and provides a good balance between speed and precision.

Water Jet Cutting:

High-pressure water mixed with an abrasive substance cuts the tubing. This method is excellent for cutting without generating heat, preserving the materials properties.

3. Deburring and Finishing:

After cutting, the edges of the tubing may have burrs or sharp edges. Deburring tools, grinders, or sanders are used to smooth the edges and ensure a clean finish.

4. Inspection and Quality Control:

The cut pieces are inspected for accuracy in length, quality of cut, and any defects. This step ensures that the cut-to-length tubes meet the specified requirements.

Why cut-the tube to-length?

1. Customization:

Cut-to-length tubing allows manufacturers to provide customized lengths as per the specific needs of the customers, ensuring a perfect fit for their applications.

2. Efficiency:

Reduces the need for further processing at the customers end, saving time and labor costs.

3. Waste Reduction:

Minimizes material waste by cutting the tubing to the exact required lengths, promoting cost-effectiveness and environmental sustainability.

4. Inventory Management:

Simplifies inventory management by reducing the need to store various lengths of tubing, as only the required lengths are produced and stocked.

Applications of Cut-to-Length Steel Tubing

1. Construction:

Used in structural frameworks, scaffolding, and support beams where precise lengths are critical for structural integrity.

2. Automotive:

Applied in manufacturing exhaust systems, drive shafts, and structural components where exact dimensions are essential.

3. HVAC Systems:

Used in heating, ventilation, and air conditioning systems, including ductwork and piping, requiring precise lengths for proper installation.

4. Furniture:

Employed in the production of frames and supports for furniture, where custom lengths ensure a perfect fit and structural stability.

5. Industrial Equipment:

Utilized in the fabrication of machinery, conveyors, and other industrial equipment where specific lengths are necessary for assembly and function.

Cut-to-length Steel Tubing

-

-

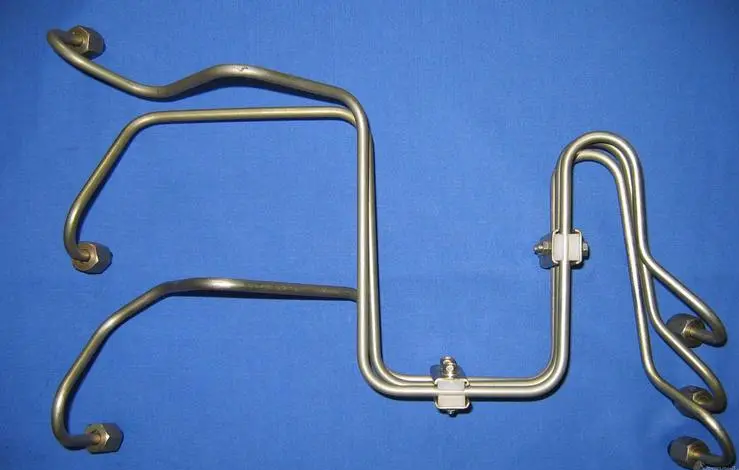

Hydraulic Hard Tubing Assembly|Hydraulic Hard Tube

VIEW MORE+ -

Cut-to-Length Steel Tubing

VIEW MORE+

请输入搜索关键字

确定