High Pressure Tubing|High-pressure Hard Tubing

VIEW MORE+- What is the Difference between Hastelloy C-276 and C-2000?

- Introduce Titanium Alloy Coiled Tubing

- What is Coiled Tubing?

- Inconel vs Incoloy Nickel Alloy Tube

- Introduce St 37.4 Black Phosphate Hydraulic Seamless Tube

- Inconel vs Hastelloy: Corrosion Resistance & High-Temp Applications

- Monel 400 vs. Stainless Steel: A Guide to Selecting Materials for Corrosive Environments

- Inconel 600 vs 601 vs 625: Nickel-based alloy pipe performance comparison and selection guide

- Difference between Monel 400 and Monel K-500 Tubes

- Classification of Nickel and Nickel Alloy

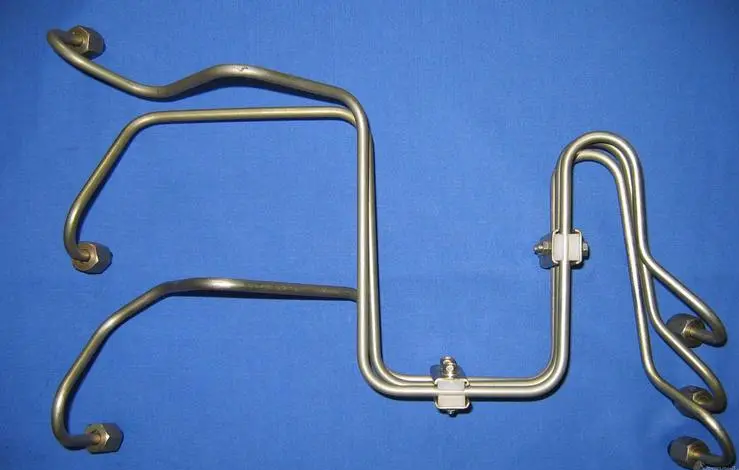

Hydraulic Hard Tubing Assembly|Hydraulic Hard Tube

Hydraulic hard tubing assembly refers to the process of creating rigid steel tubing systems designed to transport hydraulic fluid within machinery and equipment. These assemblies are crucial in hydraulic systems.

What is hydraulic hard tubing assembly?

Hydraulic hard tubing assembly refers to the process of creating rigid steel tubing systems designed to transport hydraulic fluid within machinery and equipment. These assemblies are crucial in hydraulic systems, where high-pressure fluid is used to generate, control, and transmit power. A hydraulic hard tubing assembly include rigid metal tubes, fittings, and other components used to transport hydraulic fluids within a hydraulic system. Hydraulic systems are commonly used in various industrial and automotive applications for transmitting power through the controlled use of pressurized fluids, typically oil.

The main components of a hydraulic hard tubing assembly:

1. Hard Tubing: Hydraulic hard tubing is typically made of steel or stainless steel and comes in various sizes and thicknesses. The hardness of the tubing allows it to withstand high pressures and resist deformation, ensuring reliable fluid transmission.

2. Fittings: Fittings are used to connect and secure the hard tubes together, as well as to attach the tubing to other hydraulic system components like pumps, valves, and actuators. Common types of fittings include flare fittings, compression fittings, and O-ring face seal fittings.

3. Flanges and Flange Adapters: Flanges are used to join sections of hard tubing together, providing a strong and leak-proof connection. Flange adapters help connect flanged components to other parts of the hydraulic system.

4. Clamps and Clips: These are used to secure the tubing in place, preventing movement and vibration, which could lead to damage or leaks.

5. Seals and O-rings: These components ensure that the connections between tubes and fittings are leak-proof, preventing hydraulic fluid from escaping.

6. Nuts and Bolts: These are used to fasten flanges, flange adapters, and other components securely.

7. Hydraulic Fluid: The hydraulic fluid, usually oil-based, is circulated through the tubing assembly under pressure to transmit power within the hydraulic system.

Hydraulic hard tubes typically use the following materials:

1. Carbon Steel Tubes: This is the most common material with good mechanical properties and durability, suitable for most hydraulic systems. Seamless steel tubes or precision cold-drawn steel tubes are usually used.

2. Stainless Steel Tubes: Used in environments requiring high corrosion resistance, such as marine, chemical, food, and pharmaceutical industries. Stainless steel tubes have excellent corrosion resistance and high strength.

3. Copper and Brass Tubes: Mainly used in small hydraulic systems, especially where good thermal conductivity and corrosion resistance are needed. These tubes have good machinability and oxidation resistance.

4. Alloy Steel Tubes: Used for special applications requiring high strength and high temperature resistance. Common alloy steel tubes include chrome-molybdenum steel tubes, which have higher strength and heat resistance.

5. Aluminum Tubes: Used in applications requiring high lightweight properties, such as aerospace and automotive industries. Aluminum tubes are lightweight and have good corrosion resistance.

Hydraulic hard tubing assembly

-

-

Hydraulic Hard Tubing Assembly|Hydraulic Hard Tube

VIEW MORE+ -

Cut-to-Length Steel Tubing

VIEW MORE+

请输入搜索关键字

确定