High Pressure Tubing|High-pressure Hard Tubing

VIEW MORE+- What is the Difference between Hastelloy C-276 and C-2000?

- Introduce Titanium Alloy Coiled Tubing

- What is Coiled Tubing?

- Inconel vs Incoloy Nickel Alloy Tube

- Introduce St 37.4 Black Phosphate Hydraulic Seamless Tube

- Inconel vs Hastelloy: Corrosion Resistance & High-Temp Applications

- Monel 400 vs. Stainless Steel: A Guide to Selecting Materials for Corrosive Environments

- Inconel 600 vs 601 vs 625: Nickel-based alloy pipe performance comparison and selection guide

- Difference between Monel 400 and Monel K-500 Tubes

- Classification of Nickel and Nickel Alloy

High Pressure Tubing|High-pressure Hard Tubing

High-pressure hard tubing is commonly used in various industrial, automotive, hydraulic, and fluid handling applications where the pressure requirements exceed what flexible tubing or hoses can handle.

What is high-pressure hard tubing?

High-pressure hard tubing is for high-pressure applications, using like steel, stainless steel that can withstand high pressure. These materials are used to create rigid or semi-rigid tubing or piping systems designed for the safe transport of fluids or gases under high pressure. High-pressure hard tubing typically refers to rigid or semi-rigid tubing materials designed to withstand and contain fluids or gases at elevated pressure levels. This tubing is commonly used in various industrial, automotive, hydraulic, and fluid handling applications where the pressure requirements exceed what flexible tubing or hoses can handle. Offering durability, corrosion resistance, and the ability to handle wide temperature ranges, they ensure safe and efficient fluid transfer in demanding environments. Specialized fittings and connectors are often necessary to ensure secure sealing and integration within the system, distinguishing them from flexible tubing alternatives.

1. High-pressure hard tubing materials:

High-pressure hard tubing can be made from a variety of materials, depending on the specific application and the compatibility requirements of the fluid or gas being transported. Common materials include stainless steel, carbon steel, aluminum, copper.

1.1. Stainless Steel:

- 304 Stainless Steel: This is a common grade known for its general corrosion resistance and versatility.

- 316 Stainless Steel: It offers enhanced corrosion resistance, making it suitable for more aggressive environments, including those with chloride exposure.

- Duplex Stainless Steels: These alloys (e.g., 2205) provide excellent strength and resistance to pitting and crevice corrosion.

1.2. Carbon Steel:

- SAE 1010-1020: These are low carbon steels used in applications where moderate strength and cost-effectiveness are important.

- SAE 4130: A higher-strength alloy steel used in high-pressure applications like hydraulic systems.

1.3. Copper:

- Copper-Nickel Alloys (e.g., 90/10 and 70/30): These alloys offer good corrosion resistance and are often used in marine and offshore applications.

1.4. Aluminum:

- Aluminum 6061-T6: This alloy combines good strength with lightweight properties, making it suitable for certain high-pressure applications.

1.5. Alloy Materials:

- For specialized high-pressure requirements, various alloy materials, such as Inconel, Monel, and Hastelloy, may be used depending on the specific needs of the application.

When selecting a material grade, its important to consult relevant industry standards, manufacturer specifications, and engineering guidelines to ensure that the chosen material can safely withstand the intended operating conditions. Additionally, factors like welding compatibility, ease of fabrication, and cost should also be considered during material selection for high-pressure hard tubing.

2. High-pressure hard tubing Rigidity:

Unlike flexible tubing or hoses, hard tubing is rigid or semi-rigid, maintaining its shape even under high-pressure conditions. This rigidity ensures that the tubing wont collapse or expand, which can be crucial for certain applications.

3. High-pressure hard tubing Pressure Ratings:

High-pressure hard tubing is designed and manufactured to withstand specific pressure ratings. These ratings are typically indicated by the manufacturer and should be chosen based on the maximum pressure the system will experience.

4.High-pressure hard tubing Fittings and Connections:

Proper fittings and connections are essential when working with high-pressure tubing. Ensuring a secure and leak-free connection is critical for safety and efficiency. Compression fittings, ferrules, flare fittings, and welded connections are common methods for joining hard tubing.

5. High-pressure hard tubing Application Areas:

High-pressure hard tubing is used in a wide range of industries and applications, such as hydraulic systems, pneumatic systems, high-pressure gas lines, oil and gas exploration and production, automotive brake lines, and instrumentation systems.

6. High-pressure hard tubing Safety Considerations:

Safety is paramount when working with high-pressure systems. Proper installation, maintenance, and regular inspection of the tubing and fittings are crucial to prevent leaks, bursts, and other potential hazards.

7. High-pressure hard tubing Corrosion Resistance:

Depending on the environment and the fluids being transported, the tubing material may need to be corrosion-resistant. Stainless steel, for example, is often chosen for its resistance to corrosion.

8. High-pressure hard tubing Customization:

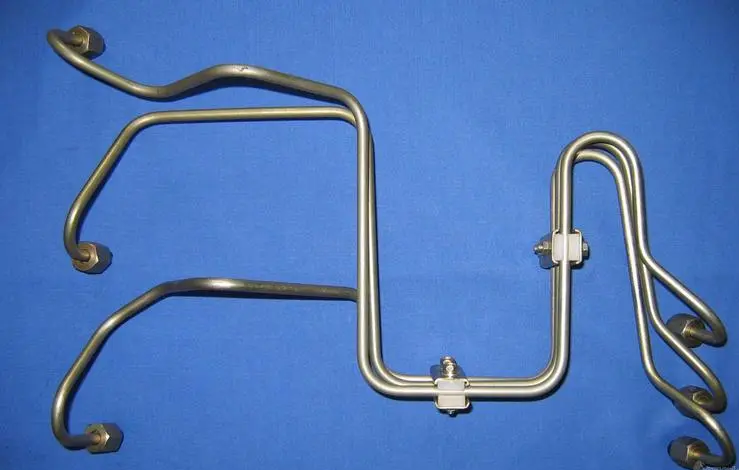

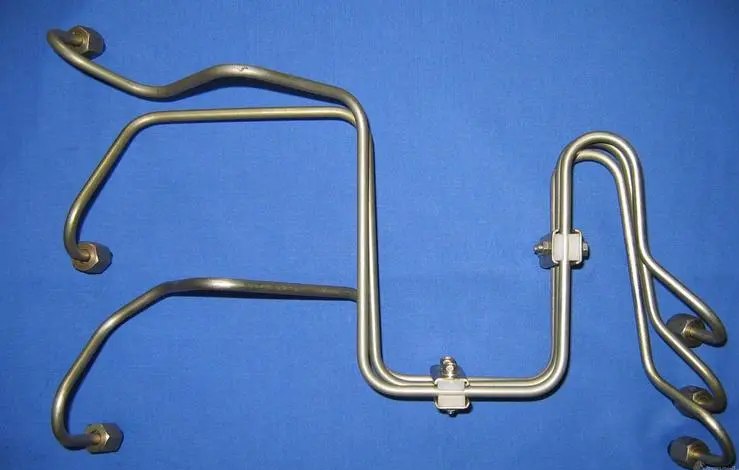

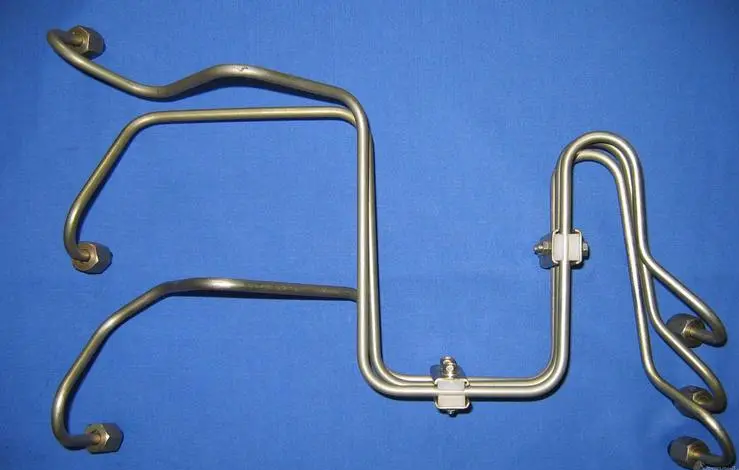

Customization of high-pressure hard tubing involves the ability to tailor the tubing to fit specific applications and configurations by custom-cutting and bending it as needed. This customization not only ensures a precise fit but also minimizes the requirement for complex fittings and reduces potential leak points in the system. By adapting the tubing to the exact requirements of the application, this approach enhances efficiency, reliability, and safety, particularly in environments where precise fluid containment is crucial. Additionally, custom-cut and bent tubing can optimize space utilization and streamline installation processes, further enhancing the overall performance of high-pressure systems.

High-pressure hard tubing|High Pressure Tubing

- PREV::NO DATA

- NEXT:Hydraulic Hard Tubing Assembly|Hydraulic Hard Tube

-

-

Hydraulic Hard Tubing Assembly|Hydraulic Hard Tube

VIEW MORE+ -

Cut-to-Length Steel Tubing

VIEW MORE+

请输入搜索关键字

确定