High Pressure Tubing|High-pressure Hard Tubing

VIEW MORE+- What is the Difference between Hastelloy C-276 and C-2000?

- Introduce Titanium Alloy Coiled Tubing

- What is Coiled Tubing?

- Inconel vs Incoloy Nickel Alloy Tube

- Introduce St 37.4 Black Phosphate Hydraulic Seamless Tube

- Inconel vs Hastelloy: Corrosion Resistance & High-Temp Applications

- Monel 400 vs. Stainless Steel: A Guide to Selecting Materials for Corrosive Environments

- Inconel 600 vs 601 vs 625: Nickel-based alloy pipe performance comparison and selection guide

- Difference between Monel 400 and Monel K-500 Tubes

- Classification of Nickel and Nickel Alloy

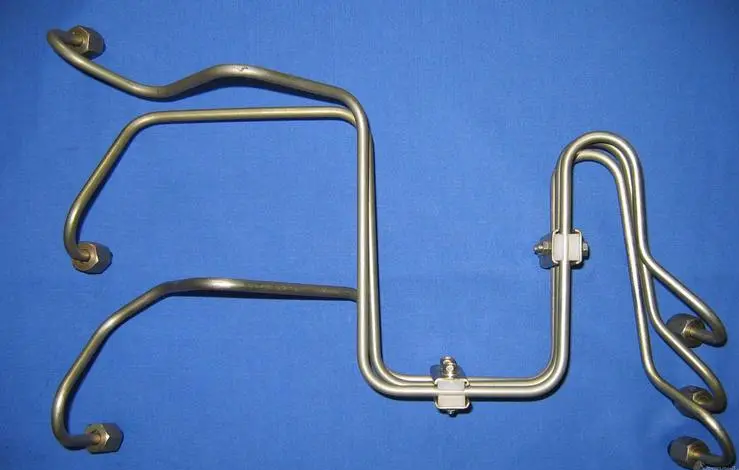

Hydraulic Tube Assembly|Hydraulic Steel Tube Assembly

What is hydraulic tube assembly? A hydraulic tube assembly refers to the arrangement of hydraulic tubes, fittings, and connectors used to transmit fluid power in hydraulic systems.

What is hydraulic tube assembly?

A hydraulic tube assembly refers to the arrangement of hydraulic tubes, fittings, and connectors used to transmit fluid power in hydraulic systems. Hydraulic systems rely on the principle of using pressurized fluid to generate and transmit power, and hydraulic tube assemblies play a crucial role in ensuring the proper flow of hydraulic fluid between various components.

Components of a Hydraulic Tube Assembly:

1. Hydraulic Tubes: These are typically rigid or flexible pipes that carry hydraulic fluid under pressure. Hydraulic tubes are usually made of steel or other materials with high strength and resistance to corrosion and pressure.

2. Fittings: Fittings are used to connect and join hydraulic tubes together or to other hydraulic components. Common types of fittings include straight connectors, elbows, tees, and adapters. Fittings are often threaded or use other connection methods such as flared ends or compression fittings.

3. Connectors: Connectors are used to attach hydraulic tubes to hydraulic components such as valves, pumps, cylinders, and reservoirs. They provide a secure and leak-free connection between the tube and the component.

4. Seals: Seals, such as O-rings or gaskets, are used in hydraulic tube assemblies to prevent fluid leakage at connection points. Seals ensure a tight and reliable seal between the tube, fittings, and connectors, even under high-pressure conditions.

How to process hydraulic tube assembly?

The assembly of hydraulic tube assemblies typically involves the following steps:

1. Tube Preparation: Hydraulic tubes may need to be cut to the desired length and deburred to remove sharp edges. The ends may also require chamfering or flaring to facilitate easy installation of fittings and connectors.

2. Fitting Installation: The fittings are threaded or connected to the ends of the hydraulic tubes using appropriate tools and techniques. Proper torque or tightening specifications should be followed to ensure a secure connection.

3. Connector Attachment: Connectors are then attached to the fittings or directly to hydraulic components, depending on the systems design. Again, proper torque or tightening procedures should be followed to ensure a reliable connection.

4. Seal Installation: Seals, such as O-rings, are placed at the connection points to prevent fluid leakage. Care should be taken to ensure the seals are properly seated and do not get damaged during installation.

5. Testing: Once the hydraulic tube assembly is complete, it is important to test the system for any leaks or pressure issues. This can be done by pressurizing the system and inspecting for leaks or using specialized testing equipment.

Hydraulic Tube Assembly Functions and Applications

- Fluid Transmission: Carrying hydraulic fluid between components in a hydraulic system.

- High-Pressure Applications: Used in systems where fluids are transmitted at very high pressures, such as in construction equipment, manufacturing machinery, and aerospace applications.

- Precision and Safety: Designed to maintain precise control of fluid flow and ensure the safety and reliability of the hydraulic system.

A hydraulic tube assembly is a component used in hydraulic systems to transport fluid under high pressure. These assemblies are crucial in various industrial and mechanical applications where fluid power is used to perform tasks.

Hydraulic steel tube assembly

- PREV:Cut-to-Length Steel Tubing

- NEXT:NO DATA

-

-

Hydraulic Hard Tubing Assembly|Hydraulic Hard Tube

VIEW MORE+ -

Cut-to-Length Steel Tubing

VIEW MORE+

请输入搜索关键字

确定