HPL Tubes|Seamless Phosphated HPL Tube

VIEW MORE+- What is the Difference between Hastelloy C-276 and C-2000?

- Introduce Titanium Alloy Coiled Tubing

- What is Coiled Tubing?

- Inconel vs Incoloy Nickel Alloy Tube

- Introduce St 37.4 Black Phosphate Hydraulic Seamless Tube

- Inconel vs Hastelloy: Corrosion Resistance & High-Temp Applications

- Monel 400 vs. Stainless Steel: A Guide to Selecting Materials for Corrosive Environments

- Inconel 600 vs 601 vs 625: Nickel-based alloy pipe performance comparison and selection guide

- Difference between Monel 400 and Monel K-500 Tubes

- Classification of Nickel and Nickel Alloy

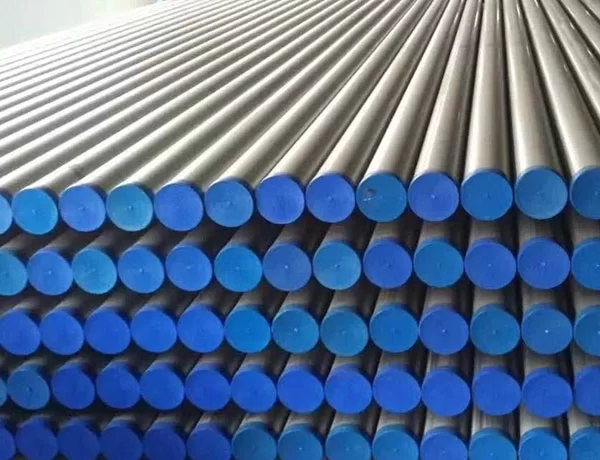

ASTM A519 Mechanical Steel Tubing|ASTM A519 Tube

What is ASTM A519 Mechanical Steel Tubing? ASTM A519 is a standard specification for seamless carbon and alloy steel mechanical tubing used for mechanical purposes.

What is ASTM A519 Mechanical Steel Tubing?

ASTM A519 is a specification that covers several grades of carbon and alloy steel mechanical tubing used in mechanical and pressure applications. This tubing is produced in both hot-finished and cold-finished conditions and is intended for use in the automotive, construction, and industrial sectors. ASTM A519 tubing is known for its high strength, durability, and excellent machinability, making it suitable for a wide range of mechanical applications where precision and reliability are paramount. Additionally, it undergoes rigorous testing to ensure adherence to specified mechanical properties and dimensional tolerances, ensuring consistent quality and performance across various industrial applications.

ASTM A519 Mechanical Steel Tubing Material Grade:

|

Material Grade |

Carbon (C) |

Manganese (Mn) |

Phosphorus (P) |

Sulfur (S) |

Silicon (Si) |

|

1010 |

0.08-0.13 |

0.30-0.60 |

0.040 max |

0.050 max |

0.100 max |

|

1020 |

0.18-0.23 |

0.30-0.60 |

0.040 max |

0.050 max |

0.100 max |

|

1026 |

0.22-0.28 |

0.60-0.90 |

0.040 max |

0.050 max |

0.100 max |

|

4130 |

0.28-0.33 |

0.40-0.60 |

0.040 max |

0.040 max |

0.150-0.350 |

|

4140 |

0.38-0.43 |

0.75-1.00 |

0.040 max |

0.040 max |

0.150-0.350 |

ASTM A519 Mechanical Steel Tubing Mechanical Properties:

|

Material Grade |

Tensile Strength (MPa) |

Yield Strength (MPa) |

Elongation (%) |

Hardness (HRB) |

|

1010 |

365 |

193 |

30 |

55 |

|

1020 |

414 |

241 |

25 |

60 |

|

1026 |

517 |

310 |

30 |

65 |

|

4130 |

760 |

655 |

20 |

85 |

|

4140 |

850 |

725 |

20 |

95 |

ASTM A519 Mechanical Steel Tubing Delivery Condition:

The tubing can be delivered in a hot-finished or cold-finished condition. ASTM A519 Mechanical Steel Tubing is delivered in either hot-finished or cold-finished condition. Hot-finished tubing is formed by heating the steel above its recrystallization temperature, followed by shaping and sizing processes, resulting in tubing with smooth surface finish and dimensional accuracy, suitable for applications requiring high strength and toughness. Conversely, cold-finished tubing undergoes additional processing such as cold drawing or cold rolling after initial tube formation to achieve precise dimensions and mechanical properties, offering improved surface quality, tighter tolerances, and enhanced suitability for precision components and critical mechanical applications. Both delivery conditions cater to distinct needs, with hot-finished tubing often preferred for structural applications, while cold-finished tubing is favored for its precision and superior surface finish.

ASTM A519 Mechanical Steel Tubing Permissible Variations in Dimensions:

ASTM A519 specifies permissible variations in dimensions such as outside diameter, wall thickness, and length. These variations are provided in the standard and depend on the specific dimensions and tolerances required.

ASTM A519 Mechanical Steel Tubing Surface Treatment:

The surface of ASTM A519 mechanical tubing is typically coated with oil or phosphate to prevent corrosion during storage and transportation. However, further surface treatment can be applied based on the application requirements.

ASTM A519 Mechanical Steel Tubing Advantages:

ASTM A519 mechanical steel tubing offers several advantages, including:

1. High strength and toughness: The tubing is made from carbon and alloy steel grades that provide excellent strength and toughness properties.

2. Wide range of sizes and shapes: A519 tubing is available in various sizes, shapes, and wall thicknesses to meet different application requirements.

3. Seamless construction: The seamless manufacturing process ensures uniformity, strength, and reliability in the tubing.

4. Versatile applications: A519 tubing is used in a wide range of applications, including automotive, machinery, construction, and industrial equipment.

ASTM A519 Mechanical Steel Tubing Applications:

ASTM A519 mechanical steel tubing is commonly used in the following applications:

1. Automotive components: Suspension parts, drive shafts, and steering components.

2. Machinery and equipment: Shafts, gears, couplings, and hydraulic cylinders.

3. Construction: Structural components, scaffolding, and support columns.

4. Industrial equipment: Heat exchangers, boilers, and pressure vessels.

ASTM A519 Mechanical Steel Tubing

-

-

Automotive Steel Tube|Automotive tubing

VIEW MORE+ -

Cold Drawn Hydraulic Tubes|Cold Drawn Galvanized Hydraulic Steel Tube

VIEW MORE+

请输入搜索关键字

确定