HPL Tubes|Seamless Phosphated HPL Tube

VIEW MORE+- What is the Difference between Hastelloy C-276 and C-2000?

- Introduce Titanium Alloy Coiled Tubing

- What is Coiled Tubing?

- Inconel vs Incoloy Nickel Alloy Tube

- Introduce St 37.4 Black Phosphate Hydraulic Seamless Tube

- Inconel vs Hastelloy: Corrosion Resistance & High-Temp Applications

- Monel 400 vs. Stainless Steel: A Guide to Selecting Materials for Corrosive Environments

- Inconel 600 vs 601 vs 625: Nickel-based alloy pipe performance comparison and selection guide

- Difference between Monel 400 and Monel K-500 Tubes

- Classification of Nickel and Nickel Alloy

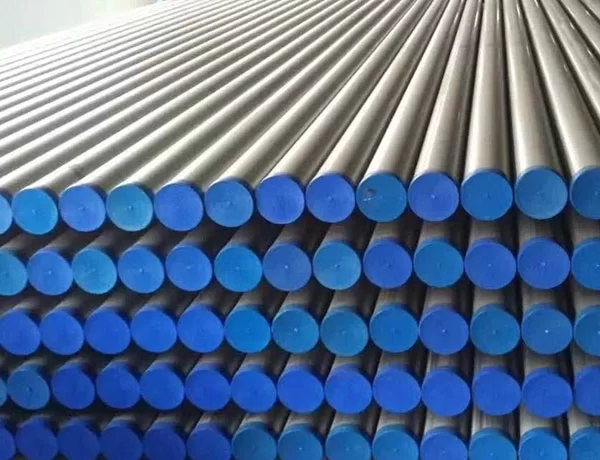

Drawn Over Mandrel Steel Tubing; DOM Steel Tubing

Drawn Over Mandrel (DOM) steel tubing is a type of steel tube that undergoes a specific manufacturing process. It involves drawing a solid steel billet over a mandrel to create a seamless tube with precise dimensions and improved mechanical properties.

What is drawn over Mandrel (DOM) steel tubing?

Drawn Over Mandrel (DOM) steel tubing undergoes a specialized manufacturing process where seamless steel tubes are cold-drawn over a mandrel, resulting in precise dimensions, enhanced mechanical properties, and a smooth surface finish. This process ensures uniform wall thickness and improved strength, making DOM tubing ideal for applications requiring high-performance mechanical components such as hydraulic cylinders, automotive parts, and structural frameworks.

Drawn Over Mandrel Steel Tubing Material Grade:

DOM steel tubing is commonly made from low-carbon or alloy steel. The specific material grade can vary based on the application requirements and manufacturer specifications. Some common material grades used for DOM steel tubing include:

1. 1010 Steel

2. 1018 Steel

3. 1020 Steel

4. 1026 Steel

5. 4130 Steel

6. 4140 Steel

Drawn Over Mandrel Steel Tubing Chemical Composition:

|

Material Grade |

Chemical Composition |

|

1010 Steel |

Carbon: 0.08-0.13%, Manganese: 0.30-0.60% |

|

1020 Steel |

Carbon: 0.18-0.23%, Manganese: 0.30-0.60% |

|

1026 Steel |

Carbon: 0.22-0.28%, Manganese: 0.60-0.90% |

|

4130 Steel |

Carbon: 0.28-0.33%, Manganese: 0.40-0.60%, Chromium: 0.80-1.10%, Molybdenum: 0.15-0.25% |

|

4140 Steel |

Carbon: 0.38-0.43%, Manganese: 0.75-1.00%, Chromium: 0.80-1.10%, Molybdenum: 0.15-0.25% |

|

1018 Steel |

Carbon: 0.15-0.20%, Manganese: 0.60-0.90% |

Drawn Over Mandrel Steel Tubing Mechanical Properties:

|

Material Grade |

Tensile Strength (MPa) |

Yield Strength (MPa) |

Elongation (%) |

|

1010 Steel |

335-475 |

180-230 |

30 min |

|

1020 Steel |

420-550 |

350-420 |

15 min |

|

1026 Steel |

590-760 |

450-590 |

15 min |

|

4130 Steel |

760-900 |

550-690 |

15 min |

|

4140 Steel |

850-1000 |

650-850 |

13 min |

|

1018 Steel |

380-480 |

220-260 |

25 min |

Drawn Over Mandrel Steel Tubing Produce Standard

ASTM A513/A513M Standard Specification for Electric-Resistance-Welded Carbon and Alloy Steel Mechanical Tubing

ASTM A519/A519M Standard Specification for Seamless Carbon and Alloy Steel Mechanical Tubing

EN 10305-2 Steel tubes for precision applications Technical delivery conditions Part 2: Welded cold-drawn tubes

JIS G3445 Carbon Steel Tubes for Machine Structural Purposes

DIN 2393-2 Welded precision steel tubes Part 2: Technical delivery conditions

SAE J524 - Seamless Low-Carbon Steel Tubing Annealed for Bending and Flaring. This standard specifies seamless cold-drawn and annealed low-carbon steel tubing for use in bending, flaring, and other similar applications. DOM steel tubing often conforms to the requirements of this standard.

Drawn Over Mandrel Steel Tubing Delivery Condition:

Dimensions and Tolerances

1. Outer Diameter Tolerance

Diameter ≤ 1.5 inches (38.1 mm): ±0.003 inches (±0.08 mm)

Diameter > 1.5 inches (38.1 mm): ±0.005 inches (±0.13 mm)

2. Wall Thickness Tolerance

Wall thickness ≤ 0.065 inches (1.65 mm): ±10%

Wall thickness > 0.065 inches (1.65 mm): ±7.5%

Mechanical Properties

1. Tensile Strength: Typical values range from 48,000 to 64,000 psi (330 to 440 MPa)

2. Yield Strength: Typical values range from 32,000 to 52,000 psi (220 to 360 MPa)

3. Elongation: Usually between 15% and 30%, depending on the specific alloy and heat treatment condition

4. Hardness: Brinell hardness values typically range from 70 to 120 HB

Chemical Composition (example for ASTM A513 Type 5)

1. Carbon (C): 0.10% to 0.20%

2. Manganese (Mn): 0.30% to 0.60%

3. Phosphorus (P): ≤ 0.040%

4. Sulfur (S): ≤ 0.050%

Straightness

The deviation should not exceed 1/16 inch (about 1.59 mm) over a 3-foot (about 0.91 meter) length.

Surface Quality

The surface of the tube should be free from cracks, seams, scabs, blisters, and other defects. Specific defect sizes and quantities are limited by detailed provisions in the standard.

Cleanliness

The inner and outer surfaces should be clean, free of significant oxide scales, rust, and other contaminants.

Heat Treatment Condition

DOM tubing can be delivered in annealed (A), normalized (N), or other specified heat treatment conditions, depending on customer requirements.

These values can be adjusted based on specific application needs, and detailed specifications should refer to relevant standard documents like ASTM A513. Different standards and steel grades may have slightly different values, but the overall requirements and ranges are similar. If there are specific application scenarios or needs, customization can be done accordingly.

Drawn Over Mandrel Steel Tubing Permissible Variations in Dimensions:

The permissible variations in dimensions for DOM steel tubing depend on the applicable standards and manufacturer specifications. Generally, these variations include tolerances for outside diameter, inside diameter, wall thickness, and length.

|

Tolerance Type |

Tolerance Specification |

|

Dimensional (OD) |

+/0.005 inches (0.13 mm) or tighter |

|

Dimensional (Wall Thickness) |

+/10% of specified wall thickness |

|

Straightness |

Maximum deviation of 0.030 inches per foot (0.25 mm per meter) |

|

Surface Finish |

Ra 1.6 micrometers (63 microinches) or better |

|

Ovality |

Maximum deviation of 0.010 inches (0.25 mm) |

|

Length |

+/1/8 inch (3.2 mm) or tighter |

Drawn Over Mandrel Steel Tubing Surface Treatment:

Drawn Over Mandrel (DOM) steel tubing often undergoes various surface treatments to enhance its performance, protect it from corrosion, and improve its appearance.

1. Pickling and Passivation

Pickling: The tubing is immersed in an acidic solution to remove oxides and scale from the surface.

Passivation: Following pickling, the tubing is treated with a passivating agent to form a protective oxide layer that improves corrosion resistance.

2. Galvanizing

Hot-Dip Galvanizing: The tubing is dipped into molten zinc, creating a thick, durable coating that offers excellent corrosion protection.

Electro-Galvanizing: The tubing is coated with zinc using an electrochemical process, providing a thinner, more uniform layer compared to hot-dip galvanizing.

3. Phosphating

This process involves applying a phosphate coating to the tubing, which enhances corrosion resistance and provides a good base for subsequent painting or coating.

4. Anodizing

Mainly used for aluminum tubing, this electrochemical process creates a thick, durable oxide layer on the surface, enhancing corrosion resistance and allowing for various color finishes.

5. Painting and Powder Coating

Painting: The tubing is coated with paint to provide a protective layer and improve aesthetic appearance.

Powder Coating: A dry powder is applied electrostatically and then cured under heat to form a hard, protective finish.

6. Oiling

A thin layer of oil is applied to the surface of the tubing to provide temporary corrosion protection during storage and transportation.

7. Mechanical Polishing

The tubing is mechanically polished to achieve a smooth, shiny surface, which is often required for aesthetic or hygiene-related applications.

8. Blasting

Sandblasting or Shot Blasting: The surface is blasted with abrasive materials to remove scale, rust, and other contaminants, creating a clean, roughened surface that enhances paint adhesion.

9. Heat Treatments

Annealing: Heating the tubing to a specific temperature and then slowly cooling it to remove internal stresses and improve ductility.

Normalizing: Heating the tubing above its critical temperature and air cooling to refine the grain structure and improve mechanical properties.

Drawn Over Mandrel Steel Tubing Advantages:

1. Enhanced Mechanical Properties: DOM steel tubing offers improved mechanical properties compared to standard welded or seamless tubes, including higher tensile and yield strengths.

2. Dimensional Accuracy: The manufacturing process ensures precise dimensions, providing tighter tolerances and consistent tube sizes.

3. Uniformity: DOM tubing exhibits uniform wall thickness and eliminates issues like seam weld defects found in welded tubes.

4. Excellent Surface Finish: DOM tubing has a smooth surface finish, suitable for applications that require superior aesthetics or reduced friction.

5. Improved Machinability: The cold-drawn process enhances the machinability of DOM steel tubing, allowing for easier fabrication and customization.

Drawn Over Mandrel Steel Tubing Applications:

DOM steel tubing finds applications in various industries, including:

Automotive and transportation: Suspension components, chassis, roll cages.

Machinery and equipment: Hydraulic cylinders, agricultural machinery, construction equipment.

Industrial and manufacturing: Conveyor systems, structural supports, material handling equipment.

Sporting goods: Bicycle frames, exercise equipment, recreational vehicles.

Drawn Over Mandrel Steel Tubing

-

-

Automotive Steel Tube|Automotive tubing

VIEW MORE+ -

Cold Drawn Hydraulic Tubes|Cold Drawn Galvanized Hydraulic Steel Tube

VIEW MORE+

请输入搜索关键字

确定