HPL Tubes|Seamless Phosphated HPL Tube

VIEW MORE+- Tube Seamless Cold Drawn Steel ASTM A269 TP316

- What is the Difference between Hastelloy C-276 and C-2000?

- Introduce Titanium Alloy Coiled Tubing

- What is Coiled Tubing?

- Inconel vs Incoloy Nickel Alloy Tube

- Introduce St 37.4 Black Phosphate Hydraulic Seamless Tube

- Inconel vs Hastelloy: Corrosion Resistance & High-Temp Applications

- Monel 400 vs. Stainless Steel: A Guide to Selecting Materials for Corrosive Environments

- Inconel 600 vs 601 vs 625: Nickel-based alloy pipe performance comparison and selection guide

- Difference between Monel 400 and Monel K-500 Tubes

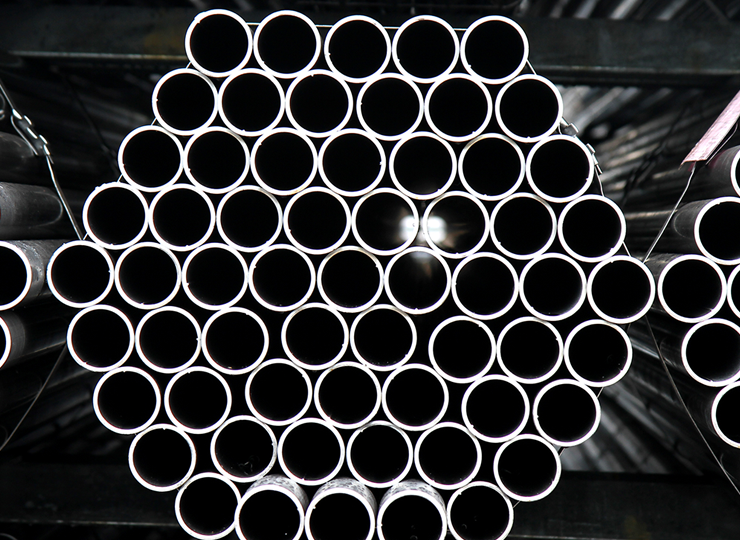

ASTM A513 Mechanical Tubing|Mechanical Tube

ASTM A513 Mechanical Tubing is a set of standards established by the American Society for Testing and Materials (ASTM) that govern the manufacturing and quality requirements for electric-resistance-welded (ERW) carbon and alloy steel tubing.

What is ASTM A513 Mechanical Tubing?

ASTM A513 mechanical tubing is a specification covering electric-resistance-welded (ERW) carbon and alloy steel tubing used for mechanical applications. These tubes are typically used in applications requiring tight tolerances, uniform wall thickness, and high strength. The tubing is manufactured from hot-rolled or cold-rolled steel, and it can be produced in various shapes such as round, square, rectangular, and special shapes. ASTM A513 tubing is commonly used in automotive parts, industrial machinery, agricultural equipment, and other structural applications where precision and strength are essential.

1. ASTM A513 Mechanical Tubing Material Grade:

ASTM A513 covers several grades of carbon and alloy steel tubing, including but not limited to:

Grade 1008/ Grade 1010/ Grade 1020/ Grade 1026/ Grade 4130/ Grade 4140

2. ASTM A513 Mechanical Tubing Chemical Composition (typical values in percentage):

|

Material Grade |

Carbon (C) |

Manganese (Mn) |

Phosphorus (P) |

Sulfur (S) |

|

1008 |

0.10 max |

0.30-0.50 |

0.040 max |

0.050 max |

|

1010 |

0.08-0.13 |

0.30-0.60 |

0.040 max |

0.050 max |

|

1020 |

0.18-0.23 |

0.30-0.60 |

0.040 max |

0.050 max |

|

1026 |

0.22-0.28 |

0.60-0.90 |

0.040 max |

0.050 max |

|

4130 |

0.28-0.33 |

0.40-0.60 |

0.040 max |

0.040 max |

|

4140 |

0.38-0.43 |

0.75-1.00 |

0.040 max |

0.040 max |

3. ASTM A513 Mechanical Tubing Mechanical Properties (minimum values):

|

Material Grade |

Tensile Strength (MPa) |

Yield Strength (MPa) |

Elongation (%) |

|

1008 |

310 |

180 |

30 |

|

1010 |

365 |

205 |

30 |

|

1020 |

420 |

275 |

25 |

|

1026 |

490 |

325 |

21 |

|

4130 |

560 |

460 |

20 |

|

4140 |

655 |

560 |

15 |

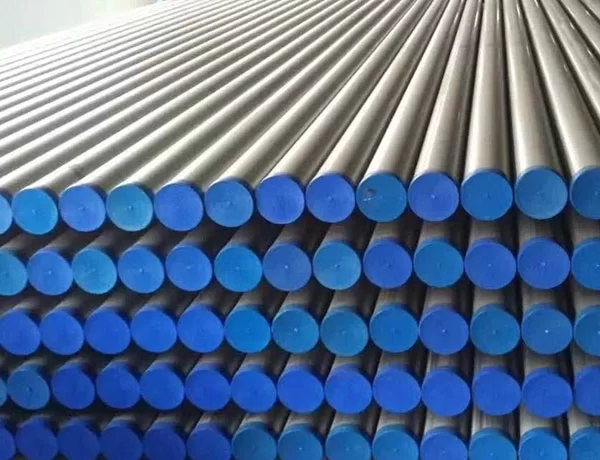

4. ASTM A513 Mechanical Tubing Delivery Condition:

The tubing is produced by electric resistance welding (ERW), which involves welding the edges of the tube together using electric resistance heating.

Type 1: Hot-rolled, welded, and cold-drawn

Type 2: Cold-rolled, welded, and cold-drawn

Type 5: Mandrel drawn over a plug or mandrel (DOM)

5. ASTM A513 Mechanical Tubing Permissible Variations in Dimensions:

ASTM A513 specifies the permissible variations in outside diameter, wall thickness, and length for mechanical tubing. These variations depend on the size and shape of the tubing and are outlined in the ASTM A513 standard.

6. ASTM A513 Mechanical Tubing Surface Treatment:

ASTM A513 tubing can be provided with a variety of surface finishes, including black, pickled, oiled, or as specified by the customer.

|

Surface Treatment |

Description |

|

Galvanizing |

Coating with a layer of zinc for corrosion protection. |

|

Painting or Powder Coating |

Application of paint or powder coating for aesthetics and corrosion resistance. |

|

Phosphating |

Formation of a protective phosphate layer to enhance corrosion resistance. |

|

Chromate Conversion Coating |

Application of a chemical film for corrosion protection. |

|

Anodizing |

Formation of an oxide layer on the surface for improved corrosion resistance. |

|

Shot Blasting or Sandblasting |

Abrasive cleaning to remove surface contaminants. |

|

Passivation |

Treatment with acid solution to remove contaminants and improve corrosion resistance. |

7. ASTM A513 Mechanical Tubing Advantages:

ASTM A513 mechanical tubing offers several advantages, such as:

- High strength and durability

- Good machinability and weldability

- Cost-effective compared to other materials

- Wide range of sizes and shapes available

- Suitable for various mechanical and structural applications

8. ASTM A513 Mechanical Tubing Applications:

ASTM A513 tubing is commonly used in a range of applications, including but not limited to:

- Machinery components

- Automotive parts

- Construction equipment

- Agricultural machinery

- Bicycle frames

- Furniture

- Exercise equipment

ASTM A513 Mechanical Tubing

-

-

Automotive Steel Tube|Automotive tubing

VIEW MORE+ -

Cold Drawn Hydraulic Tubes|Cold Drawn Galvanized Hydraulic Steel Tube

VIEW MORE+

请输入搜索关键字

确定