HPL Tubes|Seamless Phosphated HPL Tube

VIEW MORE+- What is the Difference between Hastelloy C-276 and C-2000?

- Introduce Titanium Alloy Coiled Tubing

- What is Coiled Tubing?

- Inconel vs Incoloy Nickel Alloy Tube

- Introduce St 37.4 Black Phosphate Hydraulic Seamless Tube

- Inconel vs Hastelloy: Corrosion Resistance & High-Temp Applications

- Monel 400 vs. Stainless Steel: A Guide to Selecting Materials for Corrosive Environments

- Inconel 600 vs 601 vs 625: Nickel-based alloy pipe performance comparison and selection guide

- Difference between Monel 400 and Monel K-500 Tubes

- Classification of Nickel and Nickel Alloy

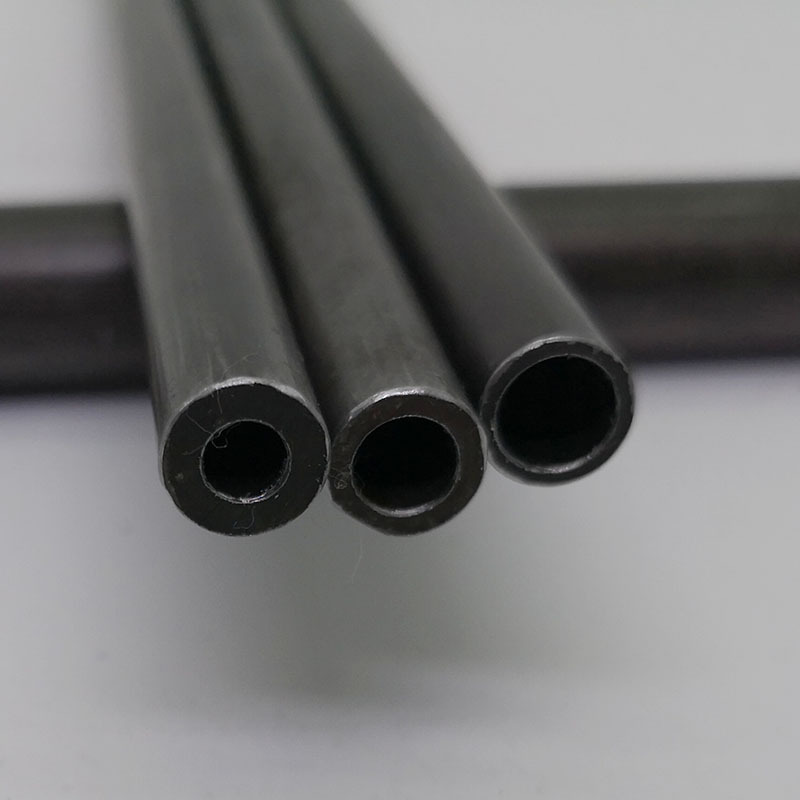

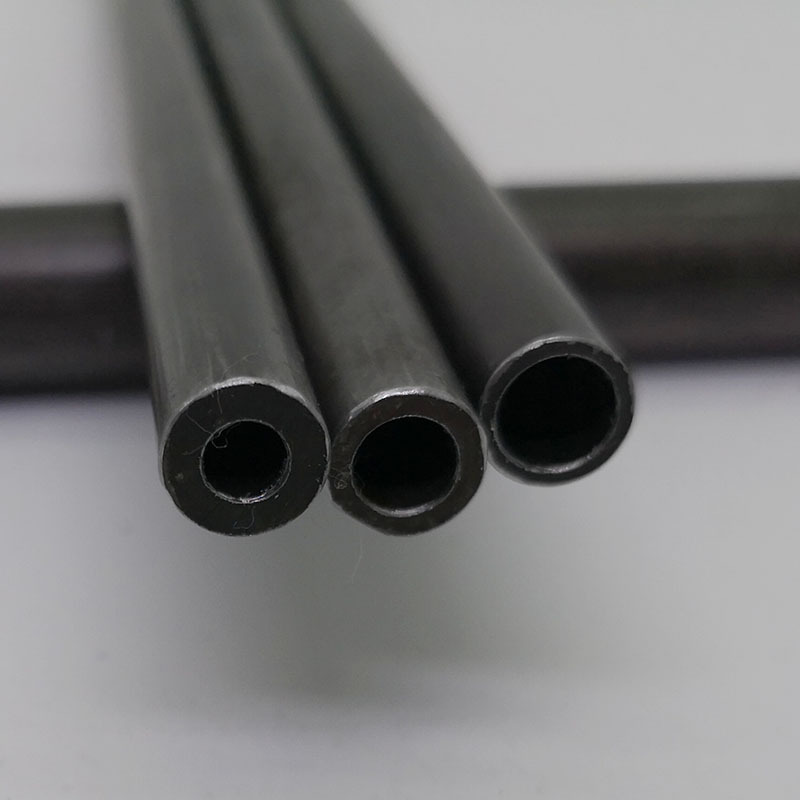

Phosphated Steel Hydraulic Tubing

Phosphated steel hydraulic tubing refers to steel tubing that has undergone a phosphate coating process to enhance its corrosion resistance and improve its surface properties for hydraulic applications.

What is Phosphated Steel Hydraulic Tubing?

Phosphated steel hydraulic tubing is steel tubing that undergoes a surface treatment process where a layer of phosphate compounds is applied chemically. This treatment serves to significantly enhance the tubings resistance to corrosion, a crucial attribute in hydraulic systems exposed to harsh operating environments and various fluids. By forming a protective barrier against rust and degradation, phosphated steel tubing ensures the durability and reliability of hydraulic components over time. Moreover, the phosphate coating improves the steels surface properties, making it more receptive to additional treatments like painting or powder coating, while also enhancing its lubricity, which is essential for the smooth operation of hydraulic systems.

1. Phosphated Steel Hydraulic Tubing Produce Standard:

- DIN 2391-1: Seamless precision steel tubes (Germany)

- EN 10305-1: Steel tubes for precision applications (European Union)

2. Phosphated Steel Hydraulic Tubing Material Grade:

- ST37.4 (DIN 2391-1)

- E235+C (EN 10305-1)

3. Phosphated Steel Hydraulic Tubing Chemical Composition:

|

Element |

ST37.4 (DIN 2391-1) |

E235+C (EN 10305-1) |

|

C |

0.17% max |

0.17% max |

|

Si |

0.35% max |

0.35% max |

|

Mn |

0.35-0.75% |

1.20-1.50% |

|

P |

0.040% max |

0.025% max |

|

S |

0.040% max |

0.015% max |

4. Phosphated Steel Hydraulic Tubing Mechanical Property:

|

Property |

ST37.4 (DIN 2391-1) |

E235+C (EN 10305-1) |

|

Tensile Strength |

340-470 MPa |

410-530 MPa |

|

Yield Strength |

235 MPa min |

235 MPa min |

|

Elongation |

25% min |

25% min |

|

Hardness (HV) |

170-210 |

170-210 |

5. Phosphated Steel Hydraulic Tubing Delivery Condition:

The phosphated steel hydraulic tubing is generally delivered in a cold-drawn and phosphate-coated condition.

6. Phosphated Steel Hydraulic Tubing Surface Treatment:

The steel tubing undergoes a phosphate coating process, which involves the application of a phosphate layer to the tubes surface. This coating enhances corrosion resistance and provides a suitable surface for subsequent sealing treatments, such as the application of an external coating or paint.

7. Phosphated Steel Hydraulic Tubing Advantages:

- Improved corrosion resistance

- Enhanced surface properties

- Better adhesion of external coatings or paints

- Increased durability and longevity

- Suitable for high-pressure hydraulic applications

8. Phosphated Steel Hydraulic Tubing Applications:

- Hydraulic systems in industrial machinery

- Automotive hydraulic brake systems

- Hydraulic cylinders

- Power steering systems

- Agricultural and construction machinery

Phosphated Steel Hydraulic Tubing

-

-

Automotive Steel Tube|Automotive tubing

VIEW MORE+ -

Cold Drawn Hydraulic Tubes|Cold Drawn Galvanized Hydraulic Steel Tube

VIEW MORE+

请输入搜索关键字

确定