HPL Tubes|Seamless Phosphated HPL Tube

VIEW MORE+- What is the Difference between Hastelloy C-276 and C-2000?

- Introduce Titanium Alloy Coiled Tubing

- What is Coiled Tubing?

- Inconel vs Incoloy Nickel Alloy Tube

- Introduce St 37.4 Black Phosphate Hydraulic Seamless Tube

- Inconel vs Hastelloy: Corrosion Resistance & High-Temp Applications

- Monel 400 vs. Stainless Steel: A Guide to Selecting Materials for Corrosive Environments

- Inconel 600 vs 601 vs 625: Nickel-based alloy pipe performance comparison and selection guide

- Difference between Monel 400 and Monel K-500 Tubes

- Classification of Nickel and Nickel Alloy

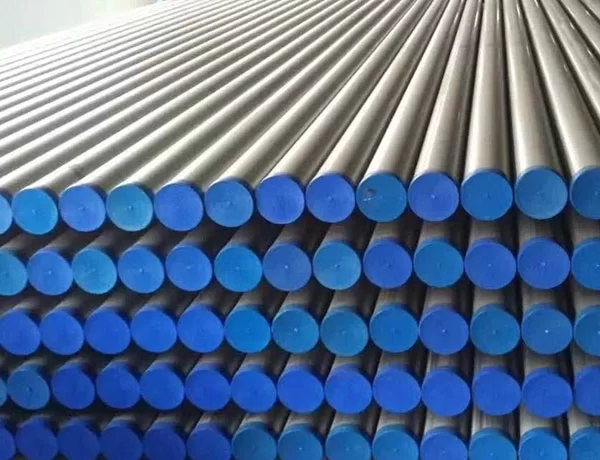

DIN2391 Galvanized Hydraulic Oil Tubing

Whats DIN2391 Galvanized Hydraulic Oil Tubing? DIN2391 Galvanized Hydraulic Oil Tubing is a type of precision steel tube that is used in hydraulic systems for conveying fluids such as oil and water under high pressure.

What is DIN2391 Galvanized Hydraulic Oil Tubing?

DIN2391 Galvanized Hydraulic Oil Tubing is a type of precision steel tube that is used in hydraulic systems for conveying fluids such as oil and water under high pressure. It is made from high-quality carbon steel and undergoes a galvanization process to protect against corrosion and increase its lifespan. DIN2391 refers to the standard specification for seamless precision steel tubes.

Why request Galvanized the DIN2391 hydraulic tubing?

DIN2391 Galvanized Hydraulic Oil Tubing is galvanized to protect it against corrosion and increase its lifespan. Galvanization is a process of applying a protective zinc coating to the surface of the tubing. This coating acts as a barrier between the steel and the environment, preventing rust and corrosion from developing.

In hydraulic systems, where the tubing is exposed to fluids such as oil and water, corrosion can lead to leaks, reduced performance, and even system failure. By galvanizing the tubing, the risk of corrosion is significantly reduced, ensuring a longer lifespan and improved performance.

Galvanization also provides a smooth surface finish, which reduces friction and ensures better fluid flow. This can help to improve the efficiency of the hydraulic system and reduce energy consumption.

Whats the Main Material Grade of DIN2391 Galvanized Hydraulic Oil Tubing?

The main material grade for DIN2391 Galvanized Hydraulic Oil Tubing is ST35, which is a low carbon steel grade that offers good cold-forming properties and high dimensional accuracy. Other material grades include ST45, ST52, and E355, which offer higher strength and durability properties. The specific material grade used depends on the specific requirements of the hydraulic system and the operating conditions.

|

Material Grade |

Chemical Composition |

Mechanical Properties |

|

St35 (E235) |

C ≤ 0.17%<br>Si ≤ 0.35%<br>Mn ≤ 1.20%<br>P ≤ 0.025%<br>S ≤ 0.025% |

ReH ≥ 235 N/mm²<br>Rm: 360-480 N/mm²<br>A ≥ 25%<br>Hardness ≤ 84 HRB |

|

St45 (E255) |

C ≤ 0.21%<br>Si ≤ 0.35%<br>Mn ≤ 1.40%<br>P ≤ 0.025%<br>S ≤ 0.025% |

ReH ≥ 255 N/mm²<br>Rm: 410-530 N/mm²<br>A ≥ 21%<br>Hardness ≤ 89 HRB |

|

St52 (E355) |

C ≤ 0.22%<br>Si ≤ 0.55%<br>Mn ≤ 1.60%<br>P ≤ 0.025%<br>S ≤ 0.025% |

ReH ≥ 355 N/mm²<br>Rm: 490-630 N/mm²<br>A ≥ 22%<br>Hardness ≤ 100 HRB |

Typical sizes of DIN2391 Galvanized Hydraulic Oil Tubing

DIN2391 Galvanized Hydraulic Oil Tubing is available in a range of sizes, typically ranging from 4mm to 120mm in outer diameter (OD) and 0.5mm to 10mm in wall thickness. The most commonly used sizes are between 6mm and 50mm OD with wall thicknesses ranging from 1mm to 5mm. However, the specific size required depends on the hydraulic systems flow rate, pressure, and operating conditions.

The advantages of DIN2391 Galvanized Hydraulic Oil Tubing

1. High strength and durability: The use of high-quality carbon steel and galvanization process makes the tubing highly resistant to corrosion and wear, ensuring a longer lifespan.

2. Precision and accuracy: The seamless manufacturing process ensures dimensional accuracy and precise tolerances, making it suitable for high-pressure hydraulic systems.

3. Smooth surface finish: The galvanization process provides a smooth surface finish, which reduces friction and ensures better fluid flow.

4. Versatility: DIN2391 Galvanized Hydraulic Oil Tubing can be used in a wide range of hydraulic applications, including in construction equipment, mining machinery, and agricultural machinery.

5. Cost-effective: The use of precision steel tubing reduces the need for additional components, such as fittings and adapters, making it a cost-effective solution for hydraulic systems.

The Applicant of DIN2391 Galvanized Hydraulic Oil Tubing

DIN2391 Galvanized Hydraulic Oil Tubing is commonly used in a variety of hydraulic applications, including:

1. Construction equipment: It is used in hydraulic cylinders, excavators, and cranes.

2. Mining machinery: It is used in drilling rigs, hydraulic roof supports, and other mining equipment.

3. Agricultural machinery: It is used in tractors, harvesters, and other farm equipment.

4. Industrial machinery: It is used in hydraulic presses, machine tools, and other industrial equipment.

5. Automotive industry: It is used in brake and fuel systems, power steering systems, and other automotive applications.

DIN 2391 standardizes seamless precision steel tubes for hydraulic systems, ensuring high-quality tubing for fluid power applications. Galvanization provides an additional protective layer against corrosion, enhancing durability and longevity, particularly crucial for hydraulic oil tubing subjected to harsh environments. These tubes are meticulously crafted with precise dimensions and smooth surfaces to facilitate efficient fluid flow and minimize pressure losses. The galvanized coating further fortifies the tubing, making it resistant to rust and abrasion, thus maintaining optimal performance over extended periods. Whether used in industrial machinery, automotive systems, or hydraulic equipment, DIN 2391 galvanized hydraulic oil tubing offers reliability, longevity, and consistent performance, essential for smooth operation in diverse hydraulic applications.

DIN2391 Galvanized Hydraulic Oil Tubing

-

-

Automotive Steel Tube|Automotive tubing

VIEW MORE+ -

Cold Drawn Hydraulic Tubes|Cold Drawn Galvanized Hydraulic Steel Tube

VIEW MORE+

请输入搜索关键字

确定