HPL Tubes|Seamless Phosphated HPL Tube

VIEW MORE+- What is the Difference between Hastelloy C-276 and C-2000?

- Introduce Titanium Alloy Coiled Tubing

- What is Coiled Tubing?

- Inconel vs Incoloy Nickel Alloy Tube

- Introduce St 37.4 Black Phosphate Hydraulic Seamless Tube

- Inconel vs Hastelloy: Corrosion Resistance & High-Temp Applications

- Monel 400 vs. Stainless Steel: A Guide to Selecting Materials for Corrosive Environments

- Inconel 600 vs 601 vs 625: Nickel-based alloy pipe performance comparison and selection guide

- Difference between Monel 400 and Monel K-500 Tubes

- Classification of Nickel and Nickel Alloy

JIS G3445 Mechanical Steel Tube

What is JIS G3445 Mechanical Steel Tube? JIS G3445 Mechanical Steel Tubing is a Japanese Industrial Standard that specifies the requirements for seamless carbon steel tubes used for machine structural purposes.

What is JIS G3445 Mechanical Steel Tube?

JIS G3445 Mechanical Steel Tube is a Japanese Industrial Standard that specifies the manufacturing and dimensional requirements for seamless and welded carbon steel tubes used in mechanical and structural applications. These tubes are typically designed to withstand highpressure environments and mechanical stresses, making them suitable for use in machinery, automotive components, construction, and other industrial sectors. The standard outlines specific tolerances for dimensions, chemical composition, mechanical properties, and testing methods to ensure the quality and reliability of the tubes for their intended purposes.

JIS G3445 Mechanical Steel Tube Material Grade:

|

Grade |

Chemical Composition (%) |

|

STKM11A |

C: 0.12 max, Si: 0.35 max, Mn: 0.60 max, P: 0.040 max, S: 0.040 max |

|

STKM12A |

C: 0.20 max, Si: 0.35 max, Mn: 0.60 max, P: 0.040 max, S: 0.040 max |

|

STKM12B |

C: 0.20 max, Si: 0.35 max, Mn: 0.60 max, P: 0.040 max, S: 0.040 max |

|

STKM12C |

C: 0.20 max, Si: 0.35 max, Mn: 0.60 max, P: 0.040 max, S: 0.040 max |

|

STKM13A |

C: 0.25 max, Si: 0.35 max, Mn: 0.300.90, P: 0.040 max, S: 0.040 max |

|

STKM13B |

C: 0.25 max, Si: 0.35 max, Mn: 0.300.90, P: 0.040 max, S: 0.040 max |

|

STKM13C |

C: 0.25 max, Si: 0.35 max, Mn: 0.300.90, P: 0.040 max, S: 0.040 max |

|

STKM14A |

C: 0.30 max, Si: 0.35 max, Mn: 0.301.00, P: 0.040 max, S: 0.040 max |

|

STKM14B |

C: 0.30 max, Si: 0.35 max, Mn: 0.301.00, P: 0.040 max, S: 0.040 max |

|

STKM14C |

C: 0.30 max, Si: 0.35 max, Mn: 0.301.00, P: 0.040 max, S: 0.040 max |

JIS G3445 Mechanical Steel Tube Mechanical Properties:

|

Grade |

Tensile Strength (MPa) |

Yield Strength (MPa) |

Elongation (%) |

|

STKM11A |

295 min |

|

30 min |

|

STKM12A |

345 min |

175 min |

30 min |

|

STKM12B |

390 min |

275 min |

25 min |

|

STKM12C |

470 min |

355 min |

20 min |

|

STKM13A |

375 min |

215 min |

30 min |

|

STKM13B |

440 min |

305 min |

20 min |

|

STKM13C |

510 min |

375 min |

15 min |

|

STKM14A |

410 min |

245 min |

25 min |

|

STKM14B |

470 min |

325 min |

15 min |

|

STKM14C |

550 min |

410 min |

10 min |

JIS G3445 Mechanical Steel Tube Delivery Condition:

The delivery condition specified in JIS G3445 for mechanical steel tubes typically depends on the manufacturing process and the requirements of the end application.

1. Hotfinished: Tubes are produced by hot rolling, hot extrusion, or other methods and are not subjected to further heat treatment after final hot forming.

2. Coldfinished: Tubes are produced by cold drawing, cold rolling, or cold finishing and are typically subjected to further heat treatment, such as annealing, to achieve the desired properties.

3. Annealed: Tubes are heat treated to remove internal stresses, improve ductility, and achieve specific mechanical properties.

4. Normalized: Tubes are subjected to a controlled heating and cooling process to refine the grain structure and achieve uniform mechanical properties throughout the material.

5. Stress relieved: Tubes are subjected to a heat treatment process to relieve internal stresses introduced during manufacturing processes such as welding or cold forming.

JIS G3445 Mechanical Steel Tubing Permissible Variations in Dimensions:

The permissible variations in dimensions are specified in the JIS G3445 standard and depend on the size and type of the tube.

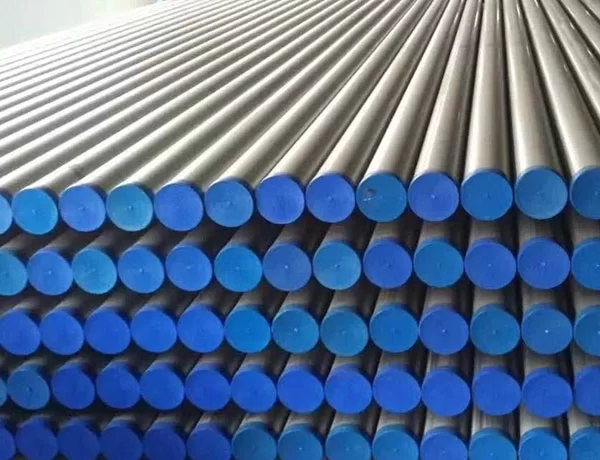

JIS G3445 Mechanical Steel Tube Surface Treatment:

The surface of the tubes can be treated by various methods such as oil coating, phosphate coating, or zinc coating for corrosion protection.

JIS G3445 Mechanical Steel Tube Advantages:

1. High Precision Manufacturing:

JIS G3445 steel tubes are manufactured using advanced cold drawing and hot rolling processes, ensuring high precision in dimensions and consistent wall thickness. This precision is crucial for applications requiring strict tolerances, such as in precision mechanical parts and highperformance equipment, ensuring tight fitting and stable operation.

2. High Strength and Toughness:

These steel tubes are made from highquality carbon steel and exhibit excellent mechanical properties after heat treatment. High strength allows them to withstand heavy loads, while good toughness prevents breakage under impact loads. This is essential for heavy machinery and structural applications, such as in construction supports and mechanical arms, providing necessary support and durability.

3. Excellent Surface Treatment:

Surface treatments, including galvanizing, coating, and pickling, significantly improve the corrosion resistance of the steel tubes. Good surface finish not only looks aesthetic but also reduces friction and wear, enhancing the lifespan. In outdoor or humid environments, such as in bridges and marine engineering, these treatments prevent rust, extending the service life of the tubes.

4. Versatile Applications:

JIS G3445 steel tubes are suitable for various industries, such as automotive manufacturing (driveshafts and structural parts), machinery (bearings and cylinders), and construction (frameworks). Their versatility meets different application needs, offering a range of options from lightweight to heavyduty. For example, in automotive manufacturing, their lightweight and highstrength characteristics help improve fuel efficiency and safety.

5. Excellent Weldability:

Due to their excellent chemical composition and uniform material, JIS G3445 steel tubes have outstanding weldability, allowing for various welding processes like MIG, TIG, and arc welding. This facilitates easy welding in complex structures, ensuring strong connections and overall structural integrity in construction and machinery manufacturing.

6. Environmental Friendliness:

The manufacturing process emphasizes environmental protection by using energyefficient production methods and recycled steel, reducing the carbon footprint. For instance, using electric arc furnaces reduces energy consumption and CO2 emissions, meeting modern industrial sustainability requirements and minimizing environmental impact.

7. Excellent Fatigue Resistance:

By controlling the chemical composition and fine processing, JIS G3445 steel tubes exhibit excellent fatigue resistance under cyclic stress. Suitable for applications requiring longterm cyclic loads, such as engineering machinery and automotive components, they significantly extend service life and enhance safety.

8. Good Heat Treatment Performance:

These steel tubes can undergo various heat treatments like annealing, quenching, and tempering to enhance their hardness and toughness. Heattreated steel tubes perform better under specific conditions, suitable for demanding applications like tool manufacturing and highstrength parts.

9. Lightweight Design:

The high strengthtoweight ratio makes JIS G3445 steel tubes ideal for applications needing weight reduction without compromising strength, such as in aerospace and automotive industries. Lightweight design helps improve fuel efficiency and reduce emissions while maintaining high strength and safety.

10. Innovative Application Potential:

With technological advancements, JIS G3445 steel tubes have vast application potential in emerging fields. In smart manufacturing, robotic arms and automation equipment require highprecision and highstrength materials; in renewable energy systems, wind power generation, and solar panel supports need durable and corrosionresistant materials.

JIS G3445 Mechanical Steel Tube Applications:

JIS G3445 mechanical steel tubes find applications in various industries, including:

1. Automotive industry: Used for manufacturing components such as drive shafts, steering columns, and suspension systems.

2. Machinery industry: Used for producing parts like gears, shafts, and hydraulic cylinders.

3. Construction industry: Used in the construction of equipment and machinery.

4. General engineering applications: These tubes are suitable for various general engineering purposes, including the fabrication of frames, structures, and supports.

JIS G3445 Mechanical Steel Tube

-

-

Automotive Steel Tube|Automotive tubing

VIEW MORE+ -

Cold Drawn Hydraulic Tubes|Cold Drawn Galvanized Hydraulic Steel Tube

VIEW MORE+

请输入搜索关键字

确定