HPL Tubes|Seamless Phosphated HPL Tube

VIEW MORE+- What is the Difference between Hastelloy C-276 and C-2000?

- Introduce Titanium Alloy Coiled Tubing

- What is Coiled Tubing?

- Inconel vs Incoloy Nickel Alloy Tube

- Introduce St 37.4 Black Phosphate Hydraulic Seamless Tube

- Inconel vs Hastelloy: Corrosion Resistance & High-Temp Applications

- Monel 400 vs. Stainless Steel: A Guide to Selecting Materials for Corrosive Environments

- Inconel 600 vs 601 vs 625: Nickel-based alloy pipe performance comparison and selection guide

- Difference between Monel 400 and Monel K-500 Tubes

- Classification of Nickel and Nickel Alloy

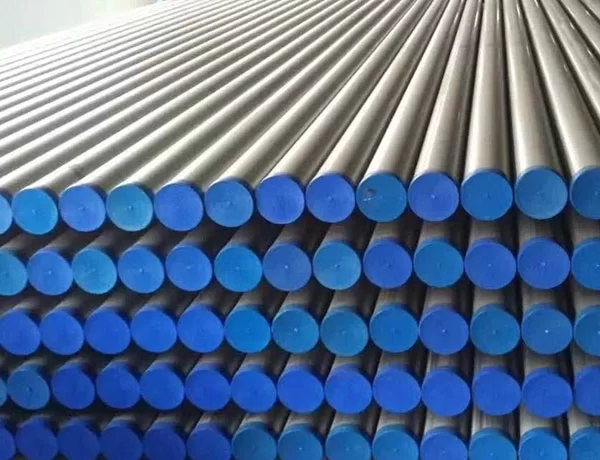

EN 10305-4 E235+N Phosphate Tubes

Phosphate-coated EN 10305-4 E235+N tubes are engineered to offer enhanced corrosion resistance, which be normalized and suitable for cold drawing, are used in applications such as hydraulic and pneumatic systems.

What is EN 10305-4 E235+N phosphate tubes?

Phosphate-coated EN 10305-4 E235+N tubes are engineered to offer enhanced corrosion resistance. The application of a phosphate coating forms a protective barrier on the tube surface, effectively preventing the onset of rust and other corrosion types. This safeguard guarantees the longevity and reliability of your hydraulic steel tubes, even when exposed to demanding environmental conditions.

EN 10305-4 E235+N Phosphate Tubes Chemical Composition:

- Carbon (C): Maximum 0.17%

- Silicon (Si): Maximum 0.35%

- Manganese (Mn): 0.40-1.20%

- Phosphorus (P): Maximum 0.025%

- Sulfur (S): Maximum 0.025%

EN 10305-4 E235+N Phosphate Tubes Mechanical Properties:

- Yield Strength (ReH): Minimum 235 N/mm²

- Tensile Strength (Rm): 340-480 N/mm²

- Elongation (A5): Minimum 25%

EN 10305-4 E235+N Phosphate Tubes Typical Size:

The typical sizes of EN 10305-4 E235+N tubes can vary depending on the manufacturer and the specific application. Common sizes often range in terms of outer diameter (OD), wall thickness, and length. These tubes are often used in hydraulic and pneumatic systems where precision and reliability are crucial.

EN 10305-4 E235+N Phosphate Tubes Application:

EN 10305-4 E235+N tubes, being normalized and suitable for cold drawing, are commonly used in applications such as hydraulic and pneumatic systems, where the mechanical properties and precision of the tubes are important. These tubes are well-suited for applications requiring good formability, high strength, and resistance to corrosion.

EN 10305-4 E235+N phosphate tubes

-

-

Automotive Steel Tube|Automotive tubing

VIEW MORE+ -

Cold Drawn Hydraulic Tubes|Cold Drawn Galvanized Hydraulic Steel Tube

VIEW MORE+

请输入搜索关键字

确定