HPL Tubes|Seamless Phosphated HPL Tube

VIEW MORE+- What is the Difference between Hastelloy C-276 and C-2000?

- Introduce Titanium Alloy Coiled Tubing

- What is Coiled Tubing?

- Inconel vs Incoloy Nickel Alloy Tube

- Introduce St 37.4 Black Phosphate Hydraulic Seamless Tube

- Inconel vs Hastelloy: Corrosion Resistance & High-Temp Applications

- Monel 400 vs. Stainless Steel: A Guide to Selecting Materials for Corrosive Environments

- Inconel 600 vs 601 vs 625: Nickel-based alloy pipe performance comparison and selection guide

- Difference between Monel 400 and Monel K-500 Tubes

- Classification of Nickel and Nickel Alloy

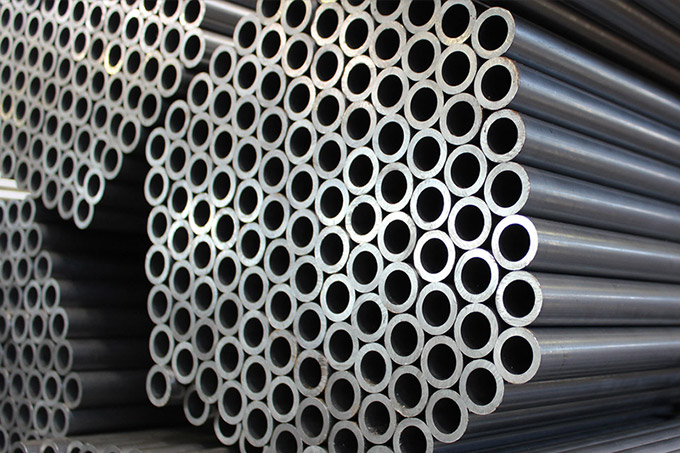

DIN2391 NBK Tube|DIN2391 Bright Tube

DIN2391 High-Precision Cold-Drawn Bright Precision Seamless Steel Tube is a specialized steel tube used in hydraulic systems and the automotive industry.

|

Outer Diameter (mm) |

Wall Thickness (mm) |

Tolerance (mm) |

|

4 |

0.5 - 1 |

±0.05 |

|

6 |

0.5 - 1 |

±0.05 |

|

8 |

0.5 - 1 |

±0.05 |

|

10 |

0.5 - 1.5 |

±0.05 |

|

12 |

0.5 - 1.5 |

±0.05 |

|

14 |

0.5 - 1.5 |

±0.05 |

|

16 |

0.5 - 2 |

±0.08 |

|

18 |

0.5 - 2 |

±0.08 |

|

20 |

0.5 - 2 |

±0.08 |

|

25 |

0.5 - 2 |

±0.10 |

|

30 |

0.5 - 2 |

±0.10 |

|

35 |

0.5 - 2 |

±0.10 |

|

40 |

0.5 - 2.5 |

±0.15 |

|

45 |

0.5 - 2.5 |

±0.15 |

|

50 |

0.5 - 2.5 |

±0.15 |

|

55 |

0.5 - 2.5 |

±0.15 |

|

60 |

0.5 - 2.5 |

±0.15 |

|

65 |

0.5 - 2.5 |

±0.15 |

|

70 |

0.5 - 2.5 |

±0.15 |

|

Standard |

Description |

|

DIN 2391 |

German standard for seamless precision steel tubes |

|

EN 10305-1 |

European standard for steel tubes for precision applications |

|

ASTM A519 |

American standard for seamless carbon and alloy steel tubes |

|

JIS G3445 |

Japanese standard for carbon steel tubes for machine structural purposes |

|

GB/T 3639-2000 |

Chinese standard for seamless cold-drawn or cold-rolled steel tubes for precision applications |

|

ISO 8535-1 |

International Organization for Standardization standard for steel tubes for high-pressure fuel injection pipes - Part 1: Requirements for seamless cold-drawn single-wall tubes |

|

BS EN 10305-4 |

British standard for steel tubes for precision applications - Technical delivery conditions - Part 4: Seamless cold drawn tubes for hydraulic and pneumatic power systems |

|

Material Grade |

Description |

Applications |

|

St35, St45, St52 |

Carbon steel grades specified in DIN 2391 |

Automotive components, hydraulic systems |

|

E235, E355 |

Carbon steel grades specified in EN 10305-1 |

Hydraulic and pneumatic systems, precision machinery |

|

1010, 1020, 1045 |

Carbon steel grades specified in ASTM A519 |

Machinery components, automotive parts |

|

S10C, S20C, S45C |

Carbon steel grades specified in JIS G3445 |

Machine structural purposes, automotive parts |

|

20#, 45#, 25CrMo4 |

Carbon and alloy steel grades specified in GB/T 3639-2000 |

Automotive parts, mechanical engineering |

|

SUS304, SUS316 |

Austenitic stainless steel grades |

Instrumentation, medical devices |

|

1.4301, 1.4401 |

Austenitic stainless steel grades specified in EN 10305-1 |

Precision engineering, food processing |

|

Delivery Condition |

Description |

|

NBK |

Normalized, Bright Annealed, Cold Drawn - Tubes are normalized, bright annealed, and cold drawn. This condition ensures uniform properties, precise dimensions, and a smooth, shiny surface finish. |

- Length of DIN2391 High-Precision Cold-Drawn Bright Precision Seamless Steel Tube:

|

Material Grade |

Tensile Strength (MPa) |

Yield Strength (MPa) |

Elongation (%) |

Hardness (HV) |

|

St35 |

≥ 480 |

≥ 315 |

≥ 25 |

≤ 160 |

|

St45 |

≥ 580 |

≥ 420 |

≥ 15 |

≤ 170 |

|

St52 |

≥ 600 |

≥ 520 |

≥ 14 |

≤ 190 |

|

E235 |

≥ 490 |

≥ 355 |

≥ 25 |

- |

|

E355 |

≥ 640 |

≥ 490 |

≥ 22 |

- |

|

1010 |

≥ 315 |

≥ 205 |

≥ 20 |

- |

|

1020 |

≥ 420 |

≥ 275 |

≥ 15 |

- |

|

1045 |

≥ 630 |

≥ 540 |

≥ 12 |

- |

|

SUS304 |

≥ 520 |

≥ 205 |

≥ 40 |

≤ 200 |

|

SUS316 |

≥ 520 |

≥ 205 |

≥ 40 |

≤ 200 |

DIN2391 Cold-Drawn Bright Seamless Steel Tube

-

-

Automotive Steel Tube|Automotive tubing

VIEW MORE+ -

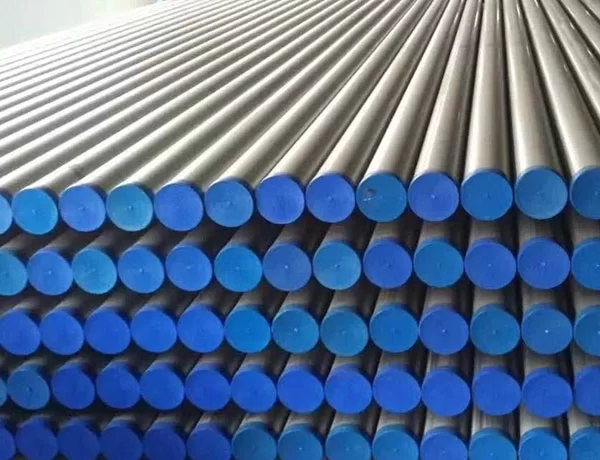

Cold Drawn Hydraulic Tubes|Cold Drawn Galvanized Hydraulic Steel Tube

VIEW MORE+

请输入搜索关键字

确定