Precision Tube Hastelloy C-2000| UNS N06200

VIEW MORE+- What is the Difference between Hastelloy C-276 and C-2000?

- Introduce Titanium Alloy Coiled Tubing

- What is Coiled Tubing?

- Inconel vs Incoloy Nickel Alloy Tube

- Introduce St 37.4 Black Phosphate Hydraulic Seamless Tube

- Inconel vs Hastelloy: Corrosion Resistance & High-Temp Applications

- Monel 400 vs. Stainless Steel: A Guide to Selecting Materials for Corrosive Environments

- Inconel 600 vs 601 vs 625: Nickel-based alloy pipe performance comparison and selection guide

- Difference between Monel 400 and Monel K-500 Tubes

- Classification of Nickel and Nickel Alloy

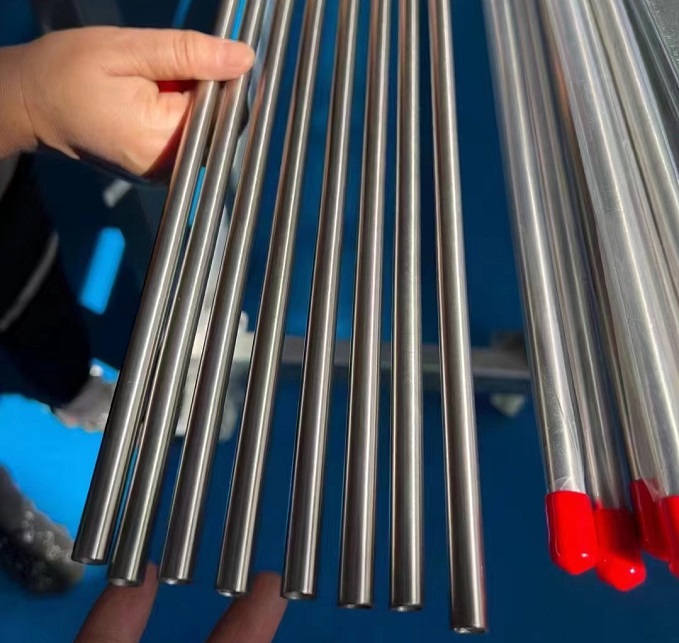

Hastelloy C-22 Precision Tube (UNS N06022)

Hastelloy C-22 seamless precision tube, at T.S. Industrial, are available in outside diameter from 6.35mm to 219.1mm. Our tubes are custom-made as per client’s requirements.

Hastelloy C-22 is a nickel-based high-temperature alloy composed of nickel, molybdenum, cobalt, tungsten and other elements. It is an all-around nickel-chromium-molybdenum-tungsten alloy with better overall corrosion resistance than other existing nickel-chromium-molybdenum alloys.

|

Grade |

Ni |

Cr |

Mo |

Fe |

W |

C |

Si |

Co |

Mn |

V |

P |

S |

|

C-22 |

Rest |

20-22.5 |

12.5-14.5 |

2-6 |

2.5-3.5 |

≤0.015 |

≤0.08 |

≤2.5 |

≤0.5 |

≤0.35 |

≤0.02 |

≤0.02 |

|

Grade |

Tensile Strength |

Yield Strength |

Elongation |

Hardness |

|

C-22 |

500-800 MPa |

200-400 MPa |

≥45% |

88 HRB-43 HRC |

-

-

Inconel 625| ASTM B444 UNS N06625| Nickel Alloy 625 tube

VIEW MORE+ -

Nimonic 75 Ni-Cr Tube | Ultra-High Temperature Creep Resistant Tube

VIEW MORE+

请输入搜索关键字

确定