Stainless Steel Tubes for Hydraulic Instrumentation

VIEW MORE+- What is the Difference between Hastelloy C-276 and C-2000?

- Introduce Titanium Alloy Coiled Tubing

- What is Coiled Tubing?

- Inconel vs Incoloy Nickel Alloy Tube

- Introduce St 37.4 Black Phosphate Hydraulic Seamless Tube

- Inconel vs Hastelloy: Corrosion Resistance & High-Temp Applications

- Monel 400 vs. Stainless Steel: A Guide to Selecting Materials for Corrosive Environments

- Inconel 600 vs 601 vs 625: Nickel-based alloy pipe performance comparison and selection guide

- Difference between Monel 400 and Monel K-500 Tubes

- Classification of Nickel and Nickel Alloy

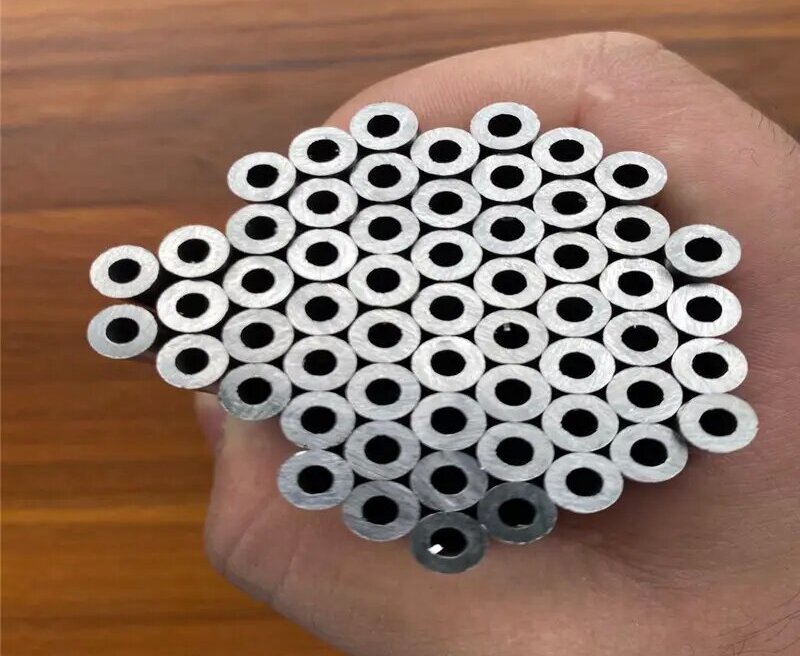

Instrumentation stainless tubes |Instrumentation tubes

Instrumentation stainless tubes are a type of stainless steel conduit specifically designed for industrial instrumentation and process control applications.Common stainless steel grades for these tubes include 304, 316, 321, etc.

Instrumentation stainless tubes are a specialized type of stainless steel conduit crafted for industrial instrumentation and process control applications. Known for their exceptional corrosion resistance, durability, and superior surface finish, these tubes are ideal for critical environments where the integrity of fluid or gas transmission is crucial. They are designed for high precision, corrosion resistance, and highpressure tolerance, making them essential in industrial systems requiring accurate measurement and control, such as those in the chemical, oil and gas, power, pharmaceutical, food, and beverage industries.

1. Instrumentation Stainless Tubes Basic Introduction:

Instrumentation stainless tubes are typically made from stainless steel, which is an alloy of iron, chromium, nickel, and other elements, known for its excellent corrosion resistance and durability.

These tubes are usually manufactured with high precision to ensure uniform dimensions and smooth internal surfaces, which is crucial in instrumentation applications where precision is essential.

2. Instrumentation Stainless Tubes Common Specifications:

Instrumentation stainless tubes come in various sizes and thicknesses to meet different application requirements. Common size ranges from small diameters suitable for capillary tubes to larger diameters suitable for transporting liquids or gases in various industrial processes and control systems.

|

316 or 304 Stainless Steel (Seamless) |

||||||||||||||||

|

Tube O.D. Size |

Wall Thickness |

|||||||||||||||

|

0.010 |

0.012 |

0.014 |

0.016 |

0.020 |

0.028 |

0.035 |

0.049 |

0.065 |

0.083 |

0.095 |

0.109 |

0.120 |

0.134 |

0.156 |

0.188 |

|

|

1/16 |

5600 |

6900 |

8200 |

9500 |

12100 |

16800 |

|

|

|

|

|

|

|

|

|

|

|

1/8 |

|

|

|

|

|

8600 |

10900 |

|

|

|

|

|

|

|

|

|

|

3/16 |

|

|

|

|

|

5500 |

7000 |

10300 |

|

|

|

|

|

|

|

|

|

1/4 |

|

|

|

|

|

4000 |

5100 |

7500 |

10300 |

|

|

|

|

|

|

|

|

5/16 |

|

|

|

|

|

|

4100 |

5900 |

8100 |

|

|

|

|

|

|

|

|

3/8 |

|

|

|

|

|

|

3300 |

4800 |

6600 |

|

|

|

|

|

|

|

|

1/2 |

|

|

|

|

|

|

2600 |

3700 |

5100 |

6700 |

|

|

|

|

|

|

|

5/8 |

|

|

|

|

|

|

|

3000 |

4000 |

5200 |

6100 |

|

|

|

|

|

|

3/4 |

|

|

|

|

|

|

|

2400 |

3300 |

4300 |

5000 |

5800 |

|

|

|

|

|

7/8 |

|

|

|

|

|

|

|

2100 |

2800 |

3600 |

4200 |

4900 |

|

|

|

|

|

1 |

|

|

|

|

|

|

|

|

2400 |

3200 |

3700 |

4200 |

4700 |

|

|

|

|

11/4 |

|

|

|

|

|

|

|

|

|

2500 |

2900 |

3300 |

3700 |

4100 |

4900 |

|

|

11/2 |

|

|

|

|

|

|

|

|

|

|

2400 |

2700 |

3000 |

3400 |

4000 |

4500 |

|

2 |

|

|

|

|

|

|

|

|

|

|

|

2000 |

2200 |

2500 |

2900 |

3200 |

|

316 or 304 Stainless Steel (Welded) |

||||||||||||||||

|

Tube O.D. Size |

Wall Thickness |

|||||||||||||||

|

0.010 |

0.012 |

0.014 |

0.016 |

0.020 |

0.028 |

0.035 |

0.049 |

0.065 |

0.083 |

0.095 |

0.109 |

0.120 |

0.134 |

0.156 |

0.188 |

|

|

1/16 |

4800 |

5900 |

7000 |

8100 |

10300 |

14300 |

|

|

|

|

|

|

|

|

|

|

|

1/8 |

|

|

|

|

|

7300 |

9300 |

|

|

|

|

|

|

|

|

|

|

3/16 |

|

|

|

|

|

4700 |

6000 |

8700 |

|

|

|

|

|

|

|

|

|

1/4 |

|

|

|

|

|

3400 |

4400 |

6400 |

8700 |

|

|

|

|

|

|

|

|

5/16 |

|

|

|

|

|

|

3400 |

5000 |

6900 |

|

|

|

|

|

|

|

|

3/8 |

|

|

|

|

|

|

2800 |

4100 |

5600 |

|

|

|

|

|

|

|

|

1/2 |

|

|

|

|

|

|

2200 |

3200 |

4300 |

5700 |

|

|

|

|

|

|

|

5/8 |

|

|

|

|

|

|

|

2500 |

3400 |

4500 |

5200 |

|

|

|

|

|

|

3/4 |

|

|

|

|

|

|

|

2100 |

2800 |

3700 |

4200 |

4900 |

|

|

|

|

|

7/8 |

|

|

|

|

|

|

|

1800 |

2400 |

3100 |

3600 |

4200 |

|

|

|

|

|

1 |

|

|

|

|

|

|

|

|

2100 |

2700 |

3100 |

3600 |

4000 |

|

|

|

|

11/4 |

|

|

|

|

|

|

|

|

|

2100 |

2400 |

2800 |

3100 |

3500 |

4200 |

|

|

1-1/2 |

|

|

|

|

|

|

|

|

|

|

2000 |

2300 |

2600 |

2900 |

3400 |

4200 |

|

2 |

|

|

|

|

|

|

|

|

|

|

|

1700 |

1900 |

2100 |

2500 |

3000 |

3. Instrumentation Stainless Tubes Common Grades:

Common stainless steel grades for these tubes include 304, 316, 321, etc. Each grade has different chemical compositions and performance characteristics, allowing for selection based on specific application requirements.

4. Instrumentation Stainless Tubes Relevant Production Standards:

Instrumentation stainless tubes may need to comply with specific industry standards and regulations, such as ASTM, ASME, or ISO standards, to ensure that their quality and performance meet the required standards.

Specific Standards for Instrumentation Stainless Steel Tubes

ASTM A269/A269M: This is a standard published by ASTM (American Society for Testing and Materials) that covers seamless and welded stainless steel tubes for general instrumentation and industrial applications. It specifies requirements for the chemical composition, mechanical properties, dimensions, and testing of stainless steel tubes.

ASTM A213/A213M: This standard, also published by ASTM, covers seamless low-alloy and stainless steel tubes for high-temperature and high-pressure applications, such as boilers, superheaters, and heat exchangers.

ASTM A270/A270M: This standard specifies requirements for stainless steel sanitary tubing, suitable for instrumentation applications in the food, pharmaceutical, and hygiene industries.

ISO 2037: The International Organization for Standardization (ISO) publishes the ISO 2037 standard, which covers stainless steel sanitary tubes for use in the food industry.

EN 10217: The European Standard (EN) series EN 10217 includes standards related to welded stainless steel tubes for general industrial and structural applications.

ASME BPE: ASMEs Bioprocessing Equipment (BPE) standard is applicable to the design and manufacture of stainless steel tubing for use in the pharmaceutical and biotechnology industries.

DIN EN 10357: This standard, published by the German Institute for Standardization (DIN), covers requirements for stainless steel tubes for general industrial applications and the food industry.

Industry-specific Standards: In some specific industries like food processing, pharmaceuticals, and chemical manufacturing, there may be industry-specific standards and regulations developed by industry associations or organizations to address unique requirements.

5. Instrumentation Stainless Tubes Performance Characteristics:

Corrosion Resistance: Stainless steel tubes exhibit excellent corrosion resistance, making them suitable for harsh or corrosive environments, such as chemical plants, petrochemical facilities, and offshore drilling platforms.

Surface Finish: These tubes often feature polished or smooth surface finishes, reducing the risk of contamination and facilitating easy cleaning and maintenance.

High Pressure and Temperature: Many instrumentation applications involve high pressures and temperatures, and stainless steel tubes can withstand these conditions without compromising their structural integrity.

Cleanliness: In industries like pharmaceuticals and food processing, cleanliness and hygiene are crucial. The corrosion-resistant and easy-to-clean nature of stainless steel instrumentation tubes makes them suitable for these applications.

6. Instrumentation Stainless Tubes Applications:

Instrumentation stainless tubes are a type of stainless steel conduit specifically designed for industrial instrumentation and process control applications. Due to their exceptional corrosion resistance, durability, and superior surface finish, these tubes are ideal for critical environments where the integrity of fluid or gas transmission is paramount. They are engineered for high precision, corrosion resistance, and high-pressure tolerance, making them essential in various industrial systems requiring accurate measurement and control.

6.1. Chemical Industry

Use: Used for transporting various corrosive chemicals and process fluids, ensuring precise control and monitoring of chemical reactions.

Example: Employed in chemical plants for connecting precision instruments such as pressure sensors, flow meters, and temperature sensors.

Technical Requirements: Must have high corrosion resistance to withstand chemical exposure and high precision to ensure accurate measurements.

6.2. Oil and Gas Industry

Use: Used for transporting and controlling oil and gas mixtures, natural gas, and sensor signal lines, ensuring safe and efficient energy production.

Example: Utilized in oil fields and natural gas processing facilities for instrumentation piping systems connected to pressure sensors, flow meters, and other monitoring equipment.

Technical Requirements: Needs to withstand high pressure, high temperature, and corrosive environments, while ensuring the accuracy and reliability of sensor data.

6.3. Power Industry

Use: Used for transporting various process fluids and coolants, ensuring the normal operation and monitoring of power equipment.

Example: Employed in power plants for precision instrumentation piping systems connected to boilers, turbines, and condensers.

Technical Requirements: Requires high temperature and high-pressure stability, as well as corrosion resistance, to ensure system safety and reliability.

6.4. Pharmaceutical Industry

Use: Used for transporting high-purity drugs and process fluids, ensuring sterility and high precision control during pharmaceutical production.

Example: Utilized in biopharmaceutical production lines for sterile piping systems connected to sensors and control equipment.

Technical Requirements: Needs extremely high cleanliness and non-toxicity, complying with GMP (Good Manufacturing Practice) standards to ensure the purity and safety of pharmaceuticals.

6.5. Food and Beverage Industry

Use: Used for transporting various food-grade liquids, ensuring hygiene and safety during the production process.

Example: Employed in dairy, beverage, and food processing plants for piping systems connected to flow meters, temperature sensors, and other monitoring equipment.

Technical Requirements: Must comply with food safety standards, such as FDA and EU regulations, ensuring product hygiene and safety, while providing high precision and corrosion resistance.

Instrumentation stainless tubes find application in various industrial sectors, including pharmaceuticals, food and beverage, oil and gas, chemical processing, and power generation. They are commonly used for transporting gases, liquids, and fluids in different industrial processes and control systems.

Instrumentation stainless tubes

-

-

Small-Diameter Heavy-Wall Tube|Heavy-Wall Tubing

VIEW MORE+ -

Super Austenitic 904L tubes|Super Austenitic 904L precision tubes

VIEW MORE+

请输入搜索关键字

确定