Stainless Steel Tubes for Hydraulic Instrumentation

VIEW MORE+- What is the Difference between Hastelloy C-276 and C-2000?

- Introduce Titanium Alloy Coiled Tubing

- What is Coiled Tubing?

- Inconel vs Incoloy Nickel Alloy Tube

- Introduce St 37.4 Black Phosphate Hydraulic Seamless Tube

- Inconel vs Hastelloy: Corrosion Resistance & High-Temp Applications

- Monel 400 vs. Stainless Steel: A Guide to Selecting Materials for Corrosive Environments

- Inconel 600 vs 601 vs 625: Nickel-based alloy pipe performance comparison and selection guide

- Difference between Monel 400 and Monel K-500 Tubes

- Classification of Nickel and Nickel Alloy

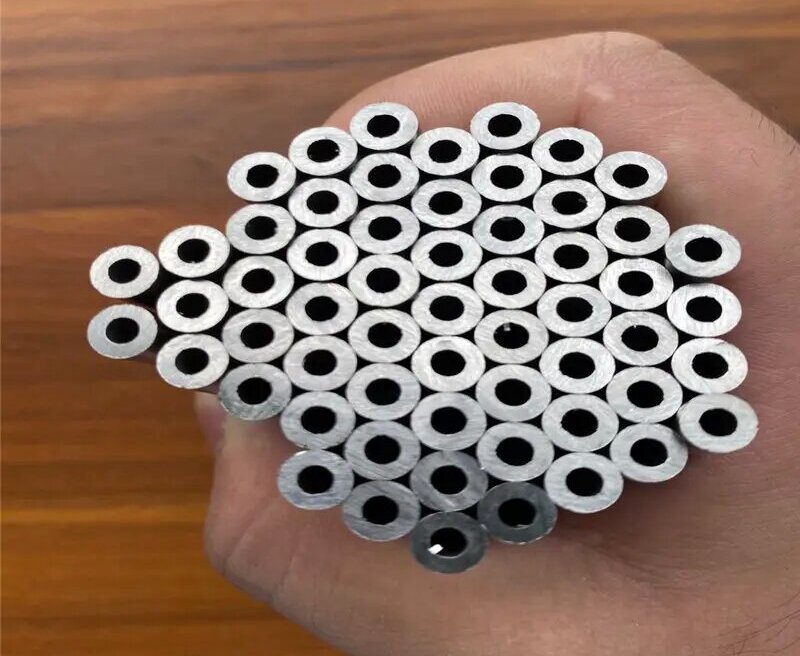

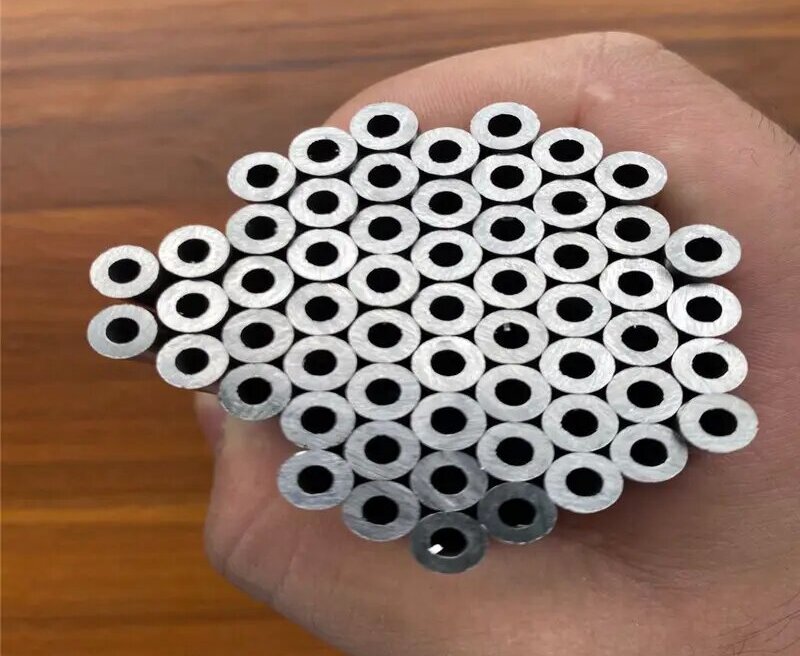

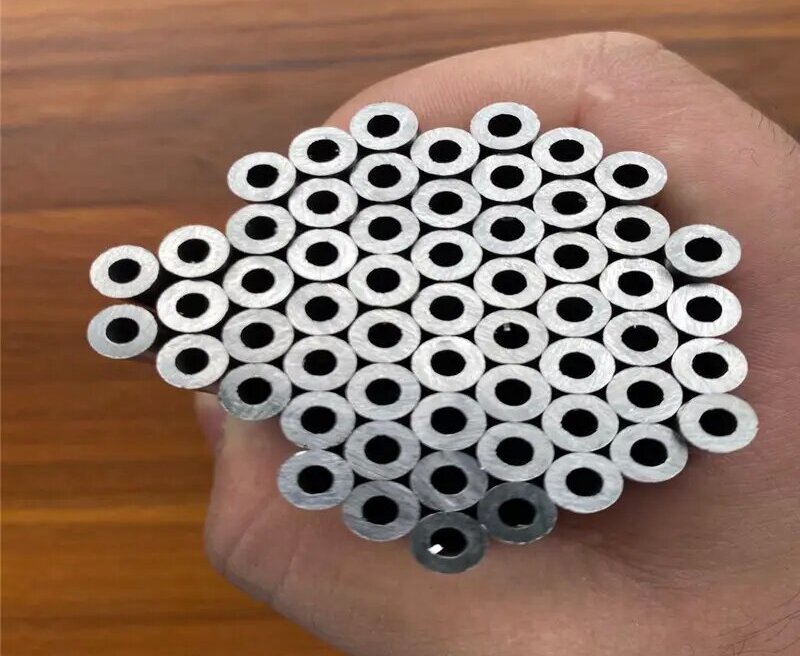

Super Austenitic 904L tubes|Super Austenitic 904L precision tubes

Super Austenitic 904L precision tubes are highly alloyed stainless steel tubes known for their excellent corrosion resistance and superior mechanical properties.

1. Basic Introduction of Super Austenitic 904L Precision Tubes:

- Super Austenitic 904L precision tubes are highly alloyed stainless steel tubes known for their excellent corrosion resistance and superior mechanical properties.

- They are primarily composed of chromium, nickel, molybdenum, and small amounts of copper, manganese, among other elements, giving them exceptional corrosion resistance.

- 904L stainless steel is renowned for its corrosion resistance in extreme environments, particularly in acidic and chloride-rich conditions.

2. Common Specifications of Super Austenitic 904L Precision Tubes:

- Outer Diameter Range: 3mm to 25mm

- Wall Thickness Range: 0.3mm to 3mm

- Length: Usually custom-made or provided according to customer requirements

3. Corresponding Grades of Super Austenitic 904L Precision Tubes:

- UNS N08904

- DIN 1.4539

- X1NiCrMoCu25-20-5

- 2RK65 (Outokumpu grade)

4. Chemical Composition of Super Austenitic 904L Precision Tubes:

|

Element |

Content (%) |

|

Chromium (Cr) |

19.0 - 23.0 |

|

Nickel (Ni) |

23.0 - 28.0 |

|

Molybdenum (Mo) |

4.0 - 5.0 |

|

Copper (Cu) |

1.0 - 2.0 |

|

Manganese (Mn) |

≤ 2.0 |

|

Silicon (Si) |

≤ 1.0 |

|

Sulfur (S) |

≤ 0.035 |

|

Phosphorus (P) |

≤ 0.045 |

5. Mechanical and Physical Properties of Super Austenitic 904L Precision Tubes:

|

Property |

Typical Value |

|

Density |

7.98 g/cm³ |

|

Tensile Strength |

≥ 490 MPa |

|

Yield Strength |

≥ 215 MPa |

|

Elongation |

≥ 35% |

|

Reduction of Area |

≥ 65% |

|

Hardness (Brinell) |

≤ 190 HB |

6. Relevant Production Standards for Super Austenitic 904L Precision Tubes:

- ASTM B677 (seamless tubes)

- ASTM B673 (welded tubes)

- ASTM B674 (welded tubesheets)

- DIN 17456

- DIN 17458

7. Performance Characteristics of Super Austenitic 904L Precision Tubes:

- High Corrosion Resistance: Especially suitable for chloride environments and acidic conditions.

- Excellent Mechanical Properties: Good strength and ductility.

- Intergranular Corrosion Resistance: Maintains high corrosion resistance even after welding.

- Low Magnetism: Suitable for special applications such as the nuclear industry.

8. Applications of Super Austenitic 904L Precision Tubes:

- Chemical Industry: Used for handling acidic media with chloride content.

- Petroleum and Gas Industry: Used for media containing hydrogen sulfide.

- Seawater Treatment Equipment: Used in desalination and seawater purification equipment.

- Medical Devices: Utilized in the manufacturing of high-demand medical instruments.

- Nuclear Industry: Used for nuclear reactor components.

- Food Processing Industry: Employed in food processing equipment.

- Fertilizer Industry: Used in fertilizer production equipment.

Super Austenitic 904L precision tubes are high-performance, corrosion-resistant tubes made from a super austenitic stainless steel alloy known as 904L. This alloy contains high levels of chromium, nickel, molybdenum, and copper, which impart exceptional resistance to pitting, crevice corrosion, and stress corrosion cracking. The precision tubes are characterized by their fine tolerance and smooth surface finish, making them suitable for demanding applications in industries such as chemical processing, oil and gas, and pharmaceuticals. Their excellent mechanical properties and ability to withstand harsh environments make 904L precision tubes a reliable choice for critical engineering applications.

Super austenitic 904L precision tubes

-

-

Small-Diameter Heavy-Wall Tube|Heavy-Wall Tubing

VIEW MORE+ -

Super Austenitic 904L tubes|Super Austenitic 904L precision tubes

VIEW MORE+

请输入搜索关键字

确定