Precision Tube Hastelloy C-2000| UNS N06200

VIEW MORE+- What is the Difference between Hastelloy C-276 and C-2000?

- Introduce Titanium Alloy Coiled Tubing

- What is Coiled Tubing?

- Inconel vs Incoloy Nickel Alloy Tube

- Introduce St 37.4 Black Phosphate Hydraulic Seamless Tube

- Inconel vs Hastelloy: Corrosion Resistance & High-Temp Applications

- Monel 400 vs. Stainless Steel: A Guide to Selecting Materials for Corrosive Environments

- Inconel 600 vs 601 vs 625: Nickel-based alloy pipe performance comparison and selection guide

- Difference between Monel 400 and Monel K-500 Tubes

- Classification of Nickel and Nickel Alloy

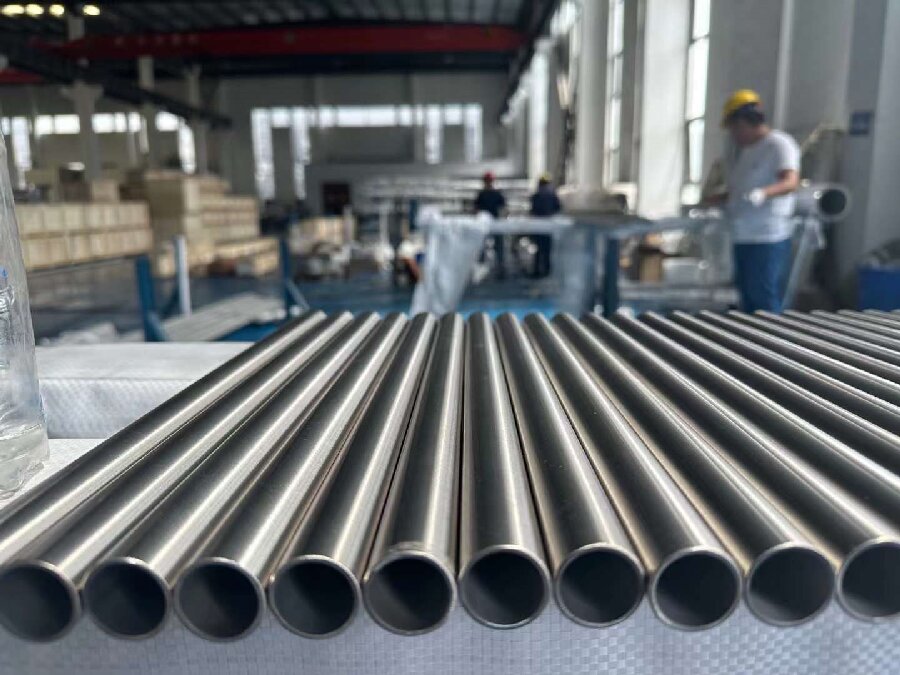

Incoloy 600 Tube|Incoloy 600 Precision Tubing

Incoloy 600 precision tubing is a type of high-temperature alloy tubing known for its excellent heat resistance and corrosion resistance, making it suitable for various high-temperature and high-pressure environments.

Incoloy 600 is a nickel-chromium alloy known for its exceptional oxidation resistance at high temperatures. It is widely used in various industries due to its ability to withstand corrosive environments and maintain mechanical properties over a wide range of temperatures.

Incoloy 600 precision tubing introduction:

Incoloy 600 precision tubing is a type of high-temperature alloy tubing known for its excellent heat resistance and corrosion resistance, making it suitable for various high-temperature and high-pressure environments.

Incoloy 600 precision tubing common specifications:

Incoloy 600 precision tubing is typically available in the following specifications:

- Outer Diameter Range: 0.5 mm - 30 mm

- Wall Thickness Range: 0.1 mm - 3 mm

- Length: Customarily supplied

Incoloy 600 precision tubing equivalent grades:

Incoloy 600 is commonly identified by the following standard grades: UNS N06600, W.Nr. 2.4816, AWS 010, among others.

Incoloy 600 precision tubing Chemical Composition:

|

Element |

Chemical Composition (%) |

|

Nickel (Ni) |

Minimum 72.0 |

|

Chromium (Cr) |

14.0 - 17.0 |

|

Iron (Fe) |

6.0 - 10.0 |

|

Manganese (Mn) |

Maximum 1.0 |

|

Silicon (Si) |

Maximum 0.5 |

|

Carbon (C) |

Maximum 0.15 |

|

Sulfur (S) |

Maximum 0.015 |

|

Copper (Cu) |

Maximum 0.5 |

Incoloy 600 precision tubing mechanical and physical properties:

|

Property |

Value |

|

Density |

8.47 g/cm³ |

|

Melting Point |

1,371°C (2,500°F) |

|

Yield Strength (Room Temperature) |

550 MPa (80,000 psi) |

|

Tensile Strength (Room Temperature) |

690 MPa (100,000 psi) |

|

Youngs Modulus (Longitudinal) |

207 GPa (30,000 ksi) |

|

Poissons Ratio (Longitudinal) |

0.3 |

Incoloy 600 precision tubing relevant production standards:

Incoloy 600 precision tubing complies with several key standards and specifications:

- ASTM B167 - This standard specifies the requirements for Incoloy 600 seamless and welded precision tubing.

- ASME SB-167 - ASME standards provide manufacturing and material requirements for Incoloy 600 precision tubing.

Incoloy 600 precision tubing features:

- High-Temperature Resistance: Incoloy 600 exhibits excellent stability and oxidation resistance at high temperatures.

- Corrosion Resistance: It has good resistance to general acids, alkalis, salts, and many corrosive media.

- Good Mechanical Properties: Incoloy 600 maintains high strength and rigidity even at high temperatures.

- Machinability: Suitable for various forming and welding processes.

Incoloy 600 precision tubing applications:

Incoloy 600 precision tubing finds widespread applications in the following sectors:

- Chemical Industry: Used in high-temperature, high-pressure reactors, heat exchangers, pipelines, and tanks.

- Nuclear Industry: Utilized for nuclear reactor components.

- Aerospace: Employed in aircraft engine components.

- Food Processing: Used in food heating equipment.

- Oil and Gas Exploration: Applied in high-temperature, high-pressure oil well equipment.

Incoloy 600 tubing, known for its exceptional resistance to oxidation and corrosion at high temperatures, is a nickel-chromium alloy widely used in demanding industrial applications. Its high-temperature stability makes it ideal for chemical processing, aerospace, nuclear industries, and heat treating equipment. The tubing, conforming to standards such as ASTM B163, B167, and B516, is manufactured using advanced processes like cold drawing and annealing, ensuring tight dimensional tolerances and superior surface finish. Incoloy 600s unique properties provide durability and performance in challenging environments, making it a reliable choice for various high-stress applications.

Incoloy 600 Precision Tubing

-

-

Inconel 625| ASTM B444 UNS N06625| Nickel Alloy 625 tube

VIEW MORE+ -

Nimonic 75 Ni-Cr Tube | Ultra-High Temperature Creep Resistant Tube

VIEW MORE+

请输入搜索关键字

确定