Stainless Steel Tubes for Hydraulic Instrumentation

VIEW MORE+- What is the Difference between Hastelloy C-276 and C-2000?

- Introduce Titanium Alloy Coiled Tubing

- What is Coiled Tubing?

- Inconel vs Incoloy Nickel Alloy Tube

- Introduce St 37.4 Black Phosphate Hydraulic Seamless Tube

- Inconel vs Hastelloy: Corrosion Resistance & High-Temp Applications

- Monel 400 vs. Stainless Steel: A Guide to Selecting Materials for Corrosive Environments

- Inconel 600 vs 601 vs 625: Nickel-based alloy pipe performance comparison and selection guide

- Difference between Monel 400 and Monel K-500 Tubes

- Classification of Nickel and Nickel Alloy

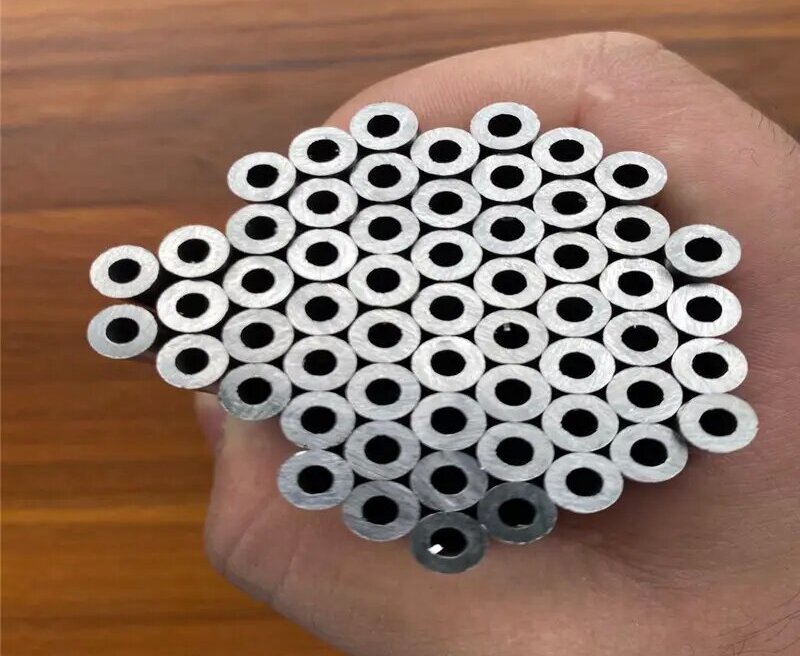

Bright Annealed (BA) Stainless Hydraulic Tube

Bright annealed (BA) stainless hydraulic tube refers to a type of stainless steel tube that undergoes a specific heat treatment process called bright annealing.

What is bright annealed (BA) stainless hydraulic tube?

Bright annealed (BA) stainless hydraulic tube refers to a type of stainless steel tube that undergoes a specific heat treatment process called bright annealing. This process involves heating the stainless steel tube to a high temperature and then cooling it rapidly in a controlled atmosphere to eliminate internal stresses and improve its mechanical properties.

Bright annealed (BA) stainless hydraulic tube material grade:

BA stainless hydraulic tubes are commonly made from austenitic stainless steel grades such as 304 (1.4301) and 316 (1.4401). These grades offer excellent corrosion resistance, high strength, and good formability, making them suitable for hydraulic applications.

|

Grade |

C |

Si |

Mn |

P |

S |

Cr |

Ni |

Mo |

N |

Other |

|

304 |

0.08 |

0.75 |

2.00 |

0.045 |

0.03 |

18.0-20.0 |

8.0-10.5 |

- |

0.10 |

- |

|

310S |

0.08 |

1.50 |

2.00 |

0.045 |

0.03 |

24.0-26.0 |

19.0-22.0 |

- |

- |

- |

|

304H |

0.04-0.10 |

0.75 |

2.00 |

0.045 |

0.03 |

18.0-20.0 |

8.0-10.5 |

- |

- |

- |

|

310L |

0.03 |

1.50 |

2.00 |

0.045 |

0.03 |

24.0-26.0 |

19.0-22.0 |

- |

- |

- |

|

317L |

0.03 |

0.75 |

2.00 |

0.045 |

0.03 |

18.0-20.0 |

11.0-15.0 |

3.0-4.0 |

- |

- |

|

304L |

0.03 |

0.75 |

2.00 |

0.045 |

0.03 |

18.0-20.0 |

8.0-12.0 |

- |

- |

- |

|

327 |

0.03 |

1.00 |

2.00 |

0.040 |

0.015 |

21.0-23.0 |

4.5-6.5 |

2.5-3.5 |

0.08 |

- |

|

32760 |

0.05 |

1.00 |

1.00 |

0.030 |

0.010 |

24.0-26.0 |

6.0-8.0 |

3.0-4.0 |

0.20 |

Cu: 0.50 |

|

316 |

0.08 |

0.75 |

2.00 |

0.045 |

0.03 |

16.0-18.0 |

10.0-14.0 |

2.0-3.0 |

0.10 |

- |

|

904L |

0.02 |

1.00 |

2.00 |

0.045 |

0.035 |

19.0-23.0 |

23.0-28.0 |

4.0-5.0 |

0.10 |

Cu: 1.0 |

|

2205 |

0.03 |

1.00 |

2.00 |

0.030 |

0.02 |

22.0-23.0 |

4.5-6.5 |

3.0-3.5 |

0.14-0.20 |

- |

|

316L |

0.03 |

0.75 |

2.00 |

0.045 |

0.03 |

16.0-18.0 |

10.0-14.0 |

2.0-3.0 |

0.10 |

- |

|

347H |

0.04-0.10 |

0.75 |

2.00 |

0.045 |

0.03 |

17.0-19.0 |

9.0-13.0 |

- |

- |

Nb: 10xC |

|

654SMO |

0.02 |

0.80 |

1.00 |

0.025 |

0.015 |

23.0-25.0 |

22.0-24.0 |

3.0-4.0 |

0.18 |

Cu: 0.50 |

|

316LOMD |

0.03 |

0.75 |

2.00 |

0.045 |

0.03 |

16.0-18.0 |

10.0-14.0 |

2.0-3.0 |

0.10 |

- |

|

310LMOD |

0.03 |

1.50 |

2.00 |

0.040 |

0.030 |

24.0-26.0 |

19.0-22.0 |

2.0-3.0 |

- |

- |

|

254SMO |

0.02 |

0.80 |

1.00 |

0.040 |

0.030 |

20.0 |

18.0 |

6.1 |

0.20 |

Cu: 0.7 |

Bright annealed (BA) stainless hydraulic tube produce standard:

ASTM Standards:

1. ASTM A269/A269M - Standard Specification for Seamless and Welded Austenitic Stainless Steel Tubing for General Service.

2. ASTM A213/A213M - Standard Specification for Seamless Ferritic and Austenitic Alloy-Steel Boiler, Superheater, and Heat-Exchanger Tubes.

3. ASTM A270 - Standard Specification for Seamless and Welded Austenitic Stainless Steel Sanitary Tubing.

JIS Standards:

1. JIS G3459 - Stainless Steel Pipes for Corrosion Resistance.

2. JIS G3463 - Stainless Steel Boiler and Heat Exchanger Tubes.

EN Standards:

1. EN 10216-5 - Seamless steel tubes for pressure purposes - Technical delivery conditions - Part 5: Stainless steel tubes.

2. EN 10217-7 - Welded steel tubes for pressure purposes - Technical delivery conditions - Part 7: Stainless steel tubes.

3. EN 10296-2 - Welded circular steel tubes for mechanical and general engineering purposes - Technical delivery conditions - Part 2: Stainless steel.

4. EN 10312 - Welded stainless steel tubes for the conveyance of water and other aqueous liquids.

Bright annealed (BA) stainless hydraulic tube surface roughness:

BA stainless hydraulic tubes have a smooth and bright surface finish. The surface roughness is typically specified in terms of Ra (arithmetical mean roughness) or Rz (mean peak-to-valley height). The surface roughness of BA tubes is generally in the range of 0.4 to 0.8 micrometers (µm), providing excellent contact and reducing the risk of corrosion or damage.

Bright annealed (BA) stainless hydraulic tube tolerance:

The dimensional tolerances for BA stainless hydraulic tubes are typically specified by the applicable production standard. These tolerances ensure the tubes dimensional accuracy and allow for proper fit and function in hydraulic systems.

Bright annealed (BA) stainless hydraulic tube advantages:

BA stainless hydraulic tubes offer several advantages, including:

1. Corrosion Resistance: The austenitic stainless steel grades used in BA tubes have high resistance to corrosion, making them suitable for applications where the tube comes into contact with corrosive fluids or environments.

2. High Strength: BA tubes have good mechanical properties, including high tensile strength and yield strength, which ensure their durability and reliability under pressure.

3. Excellent Surface Finish: The bright annealing process provides a smooth and bright surface finish, reducing the risk of surface contamination, corrosion, and wear.

4. Tight Tolerances: BA tubes are manufactured with precise dimensional tolerances, ensuring proper fit and compatibility with hydraulic components.

5. Smooth Surface: The bright annealing process gives the tubes a smooth surface finish, which helps reduce friction and minimize pressure drop in hydraulic systems. It also facilitates easy cleaning and maintenance.

Bright annealed (BA) stainless hydraulic tube application:

BA stainless hydraulic tubes are widely used in various industries and applications, including:

- Hydraulic Systems: BA tubes are used as fluid conduits in hydraulic systems, including power steering systems, braking systems, hydraulic cylinders, and other equipment that require the transmission of pressurized fluids.

- Instrumentation: BA tubes find applications in instrumentation systems, such as pressure gauges, flow meters, and control systems, where accurate and reliable fluid measurement and control are essential.

- Food and Beverage Industry: The corrosion resistance and hygienic surface finish of BA tubes make them suitable for food and beverage processing equipment, including dairy processing, breweries, and food packaging.

- Pharmaceutical and Medical Equipment: BA tubes are used in pharmaceutical and medical applications, such as fluid transfer systems, medical gas delivery systems, and sterile processing equipment, where cleanliness, corrosion resistance, and high-quality surface finish are critical.

- Petrochemical and Chemical Industry: BA tubes are employed in petrochemical plants, refineries, and chemical processing facilities for fluid transportation and processing applications, thanks to their corrosion resistance and durability.

- Automotive Industry: BA tubes can be found in automotive applications, including fuel lines, brake lines, and cooling systems, where their corrosion resistance and high strength are advantageous.

Bright annealed stainless hydraulic tubes

-

-

Small-Diameter Heavy-Wall Tube|Heavy-Wall Tubing

VIEW MORE+ -

Super Austenitic 904L tubes|Super Austenitic 904L precision tubes

VIEW MORE+

请输入搜索关键字

确定