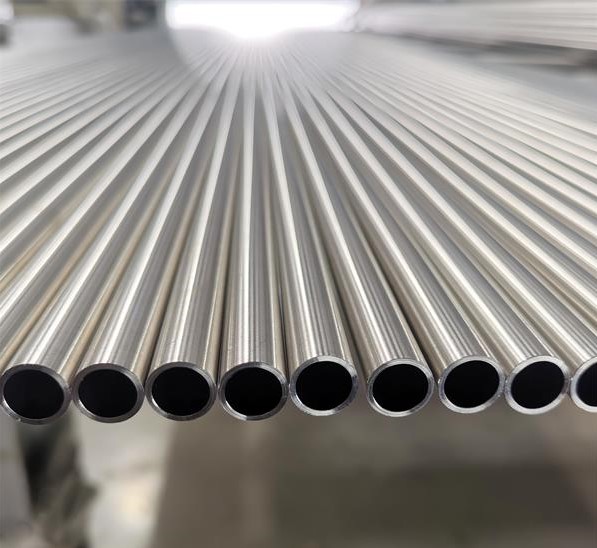

Stainless Steel Tubes for Hydraulic Instrumentation

VIEW MORE+- Tube Seamless Cold Drawn Steel ASTM A269 TP316

- What is the Difference between Hastelloy C-276 and C-2000?

- Introduce Titanium Alloy Coiled Tubing

- What is Coiled Tubing?

- Inconel vs Incoloy Nickel Alloy Tube

- Introduce St 37.4 Black Phosphate Hydraulic Seamless Tube

- Inconel vs Hastelloy: Corrosion Resistance & High-Temp Applications

- Monel 400 vs. Stainless Steel: A Guide to Selecting Materials for Corrosive Environments

- Inconel 600 vs 601 vs 625: Nickel-based alloy pipe performance comparison and selection guide

- Difference between Monel 400 and Monel K-500 Tubes

ASTM A270 Stainless Sanitary Tubing

ASTM A270 is a specification for stainless steel sanitary tubing, which intended for use in dairy and food industries, as well as in pharmaceutical and biotechnology applications.

What is ASTM A270 Stainless Sanitary Tubing?

ASTM A270 Stainless Sanitary Tubing is a specification standard for seamless and welded austenitic and ferritic/austenitic stainless steel sanitary tubing intended for use in the dairy and food industry, as well as in biotechnology, pharmaceuticals, and other hygiene-sensitive applications.

ASTM A270 Stainless Sanitary Tubing Material Grade:

The material grades specified in ASTM A270 for sanitary tubing include:

1. Austenitic Stainless Steels:

- 304 (UNS S30400)

- 304L (UNS S30403)

- 316 (UNS S31600)

- 316L (UNS S31603)

2. Ferritic/Austenitic Stainless Steels:

- 2205 (UNS S32205)

ASTM A270 Stainless Sanitary Tubing Chemical Composition (Typical Values):

|

Material Grade |

Carbon (C) |

Manganese (Mn) |

Phosphorus (P) |

Sulfur (S) |

Silicon (Si) |

Nickel (Ni) |

Chromium (Cr) |

Molybdenum (Mo) |

|

304/304L |

0.08 |

2 |

0.045 |

0.03 |

0.75 |

8.00-11.00 |

18.00-20.00 |

- |

|

316/316L |

0.08 |

2 |

0.045 |

0.03 |

0.75 |

10.00-14.00 |

16.00-18.00 |

2.00-3.00 |

|

2205 |

0.03 |

2 |

0.03 |

0.02 |

1 |

4.50-6.50 |

22.00-23.00 |

3.00-3.50 |

ASTM A270 Stainless Sanitary Tubing Mechanical Properties (Minimum Values):

|

Material Grade |

Tensile Strength (MPa) |

Yield Strength (MPa) |

Elongation (%) |

|

304/304L |

≥515 |

≥205 |

≥35 |

|

316/316L |

≥515 |

≥205 |

≥35 |

|

2205 |

≥620 |

≥450 |

≥25 |

ASTM A270 Stainless Sanitary Tubing Delivery Condition:

The tubing is typically delivered in the annealed condition.

ASTM A270 Stainless Sanitary Tubing Permissible Variations in Dimensions:

The permissible variations in dimensions for ASTM A270 sanitary tubing are specified in the standard and depend on the size and wall thickness of the tubing.

|

Dimension |

Tolerance Range |

|

Outside Diameter |

±0.015" to ±0.030" (seamless), ±0.015" to ±0.060" (welded) |

|

Wall Thickness |

±10% (seamless), ±12.5% (welded) |

|

Length |

+/- 1/8" or +/- 3mm per specified length |

|

Straightness |

Maximum bend radius or deviation from straight line over specified length |

|

End Squareness |

Within specified tolerance |

|

Surface Finish (Ra) |

According to specified requirements |

ASTM A270 Stainless Sanitary Tubing Surface Treatment:

The surface of ASTM A270 sanitary tubing is usually finished to meet the requirements of the food, dairy, and pharmaceutical industries. Common surface finishes include mill finish, polished, and electropolished.

|

Surface Treatment |

Description |

Roughness Average (Ra) |

|

Mechanical Polished |

Surface mechanically polished to achieve smoothness |

20-25 microinches (0.5-0.6 micrometers) |

|

Electropolished |

Surface treated via electrochemical process for ultra-smooth finish |

Less than 15 microinches (0.38 micrometers) |

|

Unpolished (Mill Finish) |

Surface finish directly from manufacturing process, not polished |

Varies, typically higher Ra than polished finishes |

ASTM A270 Stainless Sanitary Tubing Advantages:

- High corrosion resistance, making it suitable for use in hygienic applications.

- Smooth interior surface that allows for easy cleaning and prevents product contamination.

- Good mechanical properties, ensuring structural integrity and longevity.

- Wide range of sizes and wall thicknesses available to meet specific application requirements.

- Complies with strict industry standards for cleanliness and sanitation.

ASTM A270 Stainless Sanitary Tubing Applications:

- Food and dairy processing equipment, such as piping, fittings, and valves.

- Pharmaceutical and biotechnology manufacturing.

- Beverage and brewing industry.

- Cosmetics and personal care products manufacturing.

- Chemical processing plants.

- Semiconductor industry.

- Hospital and laboratory equipment.

ASTM A270 Stainless Sanitary Tubing

-

-

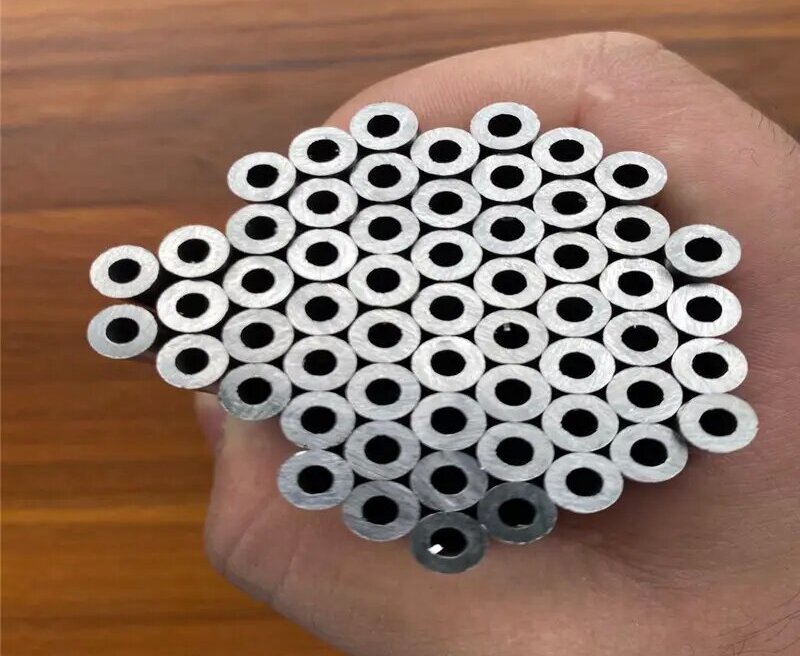

Small-Diameter Heavy-Wall Tube|Heavy-Wall Tubing

VIEW MORE+ -

Super Austenitic 904L tubes|Super Austenitic 904L precision tubes

VIEW MORE+

请输入搜索关键字

确定