Precision Tube Hastelloy C-2000| UNS N06200

VIEW MORE+- What is the Difference between Hastelloy C-276 and C-2000?

- Introduce Titanium Alloy Coiled Tubing

- What is Coiled Tubing?

- Inconel vs Incoloy Nickel Alloy Tube

- Introduce St 37.4 Black Phosphate Hydraulic Seamless Tube

- Inconel vs Hastelloy: Corrosion Resistance & High-Temp Applications

- Monel 400 vs. Stainless Steel: A Guide to Selecting Materials for Corrosive Environments

- Inconel 600 vs 601 vs 625: Nickel-based alloy pipe performance comparison and selection guide

- Difference between Monel 400 and Monel K-500 Tubes

- Classification of Nickel and Nickel Alloy

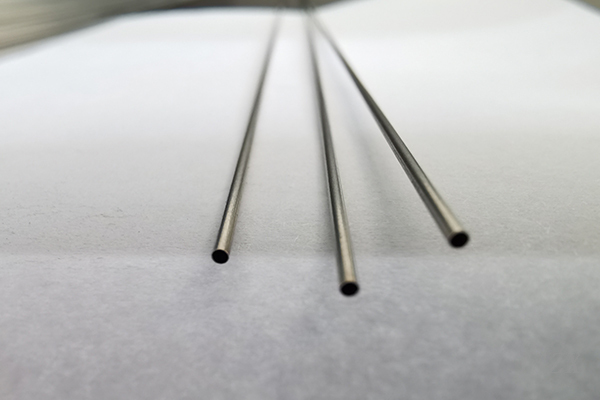

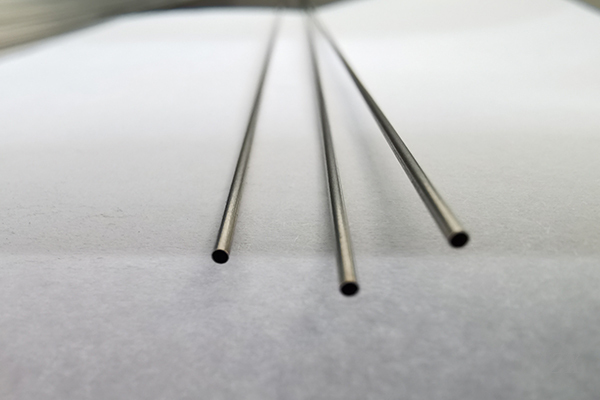

Incoloy 825 precision tubes|N08825 Tubing

Incoloy 825 tube is commonly used in applications that involve high temperatures, high pressures, and corrosive conditions, such as the chemical industry, petrochemical industry, and marine engineering.

1. Incoloy 825 Precision Tubes Basic Introduction:

Incoloy 825 is a high-performance corrosion-resistant alloy composed of nickel, chromium, iron, molybdenum, copper, and titanium, among other elements. It exhibits excellent corrosion resistance, particularly in harsh environments containing sulfuric acid, chlorides, sulfides, and more. Incoloy 825 is commonly used in applications that involve high temperatures, high pressures, and corrosive conditions, such as the chemical industry, petrochemical industry, and marine engineering.

2. Incoloy 825 Precision Tubes Common Specifications:

Incoloy 825 precision tubes are available in various standard specifications, including outer diameter, wall thickness, and length, which can be customized according to specific application requirements.

3. Incoloy 825 Precision Tubes Equivalent Grades:

Common equivalent grades for Incoloy 825 alloy include:

- Incoloy 825

- UNS N08825 (Unified Numbering System)

- Alloy 825

- 2.4858 (per the International Material Numbering System)

4. Incoloy 825 Precision Tubes Chemical Composition:

Below is the chemical composition of Incoloy 825 (expressed as mass percentages):

|

Element |

Chemical Composition (%) |

|

Nickel (Ni) |

38.0 - 46.0 |

|

Chromium (Cr) |

19.5 - 23.5 |

|

Iron (Fe) |

Minimum 22.0 |

|

Copper (Cu) |

1.5 - 3.0 |

|

Molybdenum (Mo) |

2.5 - 3.5 |

|

Titanium (Ti) |

0.6 - 1.2 |

|

Manganese (Mn) |

1.0 max |

|

Silicon (Si) |

0.5 max |

|

Sulfur (S) |

0.015 max |

|

Phosphorus (P) |

0.03 max |

|

Carbon (C) |

0.05 max |

5. Incoloy 825 Precision Tubes Mechanical Properties:

Typical mechanical properties of Incoloy 825 include (data for reference):

|

Mechanical Property |

Value |

|

Yield Strength (0.2% Offset) |

≥ 220 MPa |

|

Tensile Strength |

≥ 550 MPa |

|

Elongation |

≥ 30% |

6. Incoloy 825 Precision Tubes Physical Properties:

The physical properties of Incoloy 825 are as follows (data for reference):

|

Physical Property |

Value |

|

Density |

8.14 g/cm³ |

|

Melting Point |

1370 - 1400°C |

|

Thermal Conductivity |

12.4 W/(m·K) |

|

Linear Expansion Coefficient |

13.3 x 10^-6/°C |

7. Incoloy 825 Precision Tubes Relevant Production Standards:

The production of Incoloy 825 precision tubes typically adheres to international standards such as ASTM B423, ASTM B705, ASTM B163, ASTM B704, among others. Additionally, specific customer requirements and specifications may also apply.

8. Incoloy 825 Precision Tubes Performance Characteristics:

Incoloy 825 precision tubes are known for their performance characteristics, including:

- Excellent corrosion resistance, especially in sulfuric acid, chlorides, sulfides, and other corrosive media.

- Good high-temperature resistance, allowing for stable operation in elevated temperature environments.

- Outstanding mechanical properties, including tensile strength and yield strength.

- Ease of machining and welding, suitable for various complex engineering projects.

9. Incoloy 825 Precision Tubes Applications:

Incoloy 825 precision tubes find extensive use in various industries, including:

- Chemical Industry: Used in equipment for handling corrosive media like sulfuric acid and hydrochloric acid.

- Petrochemical Industry: Employed in refining processes, chemical plants, and offshore oil platforms.

- Marine Engineering: Utilized in seawater cooling systems, subsea pipelines, and offshore facilities.

- Food Processing: Applied in food industry processing equipment.

- Medical Equipment: Used in the manufacture of medical devices and equipment.

The Incoloy 825 precision tube is widely used in the chemical industry, nuclear industry, oil and gas extraction, and marine engineering due to its excellent corrosion resistance and mechanical properties. Its superior material characteristics enable it to perform well in various harsh working environments, making it an indispensable material in many industrial applications.

Incoloy 825 Precision Tubes

-

-

Inconel 625| ASTM B444 UNS N06625| Nickel Alloy 625 tube

VIEW MORE+ -

Nimonic 75 Ni-Cr Tube | Ultra-High Temperature Creep Resistant Tube

VIEW MORE+

请输入搜索关键字

确定