Stainless Steel Tubes for Hydraulic Instrumentation

VIEW MORE+- What is the Difference between Hastelloy C-276 and C-2000?

- Introduce Titanium Alloy Coiled Tubing

- What is Coiled Tubing?

- Inconel vs Incoloy Nickel Alloy Tube

- Introduce St 37.4 Black Phosphate Hydraulic Seamless Tube

- Inconel vs Hastelloy: Corrosion Resistance & High-Temp Applications

- Monel 400 vs. Stainless Steel: A Guide to Selecting Materials for Corrosive Environments

- Inconel 600 vs 601 vs 625: Nickel-based alloy pipe performance comparison and selection guide

- Difference between Monel 400 and Monel K-500 Tubes

- Classification of Nickel and Nickel Alloy

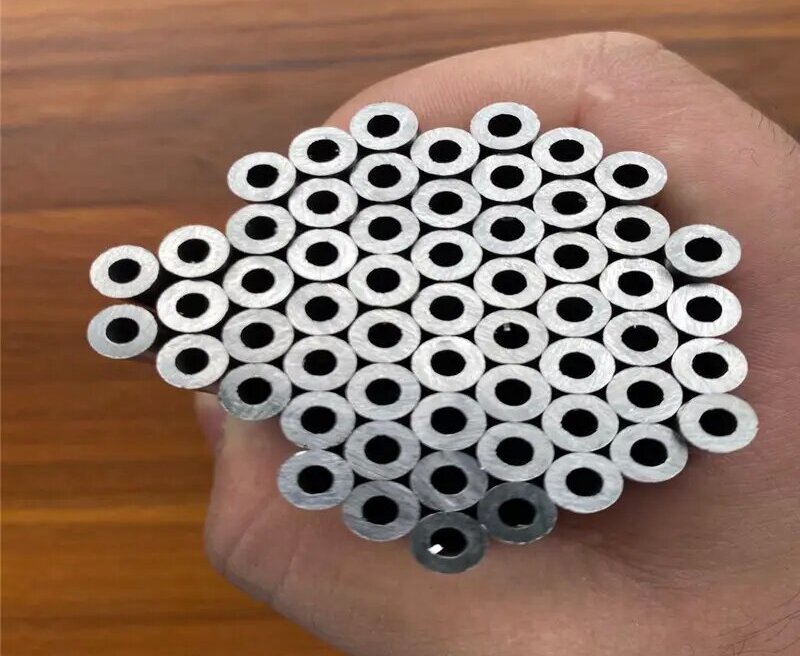

EN10216-5 Hydraulic Steel Tube

EN 10216-5 is a European standard that specifies the technical delivery conditions for seamless steel tubes for pressure purposes. Specifically, EN 10216-5 covers stainless steel tubes for hydraulic and pneumatic systems.

What is EN10216-5 hydraulic steel tube?

EN10216-5 hydraulic steel tubes are seamless stainless steel tubes manufactured according to European standards, specifically designed for use in hydraulic and pneumatic power systems. These tubes are engineered to withstand high-pressure environments and ensure reliable fluid transfer in various industrial applications. Meeting stringent mechanical properties and chemical composition requirements outlined in the EN 10216-5 standard, these tubes offer exceptional corrosion resistance and durability, making them ideal for use in demanding environments where reliability and performance are paramount.

EN10216-5 Hydraulic Steel Tube Definition:

EN10216-5 Hydraulic Steel Tube is Seamless stainless steel tubes produce as per EN10216-5 and use for hydraulic and pneumatic systems.

EN 10216-5 is a European standard that specifies the technical delivery conditions for seamless steel tubes for pressure purposes. Specifically, EN 10216-5 covers stainless steel tubes used in hydraulic and pneumatic systems. These tubes are designed to withstand high-pressure environments and provide reliable performance in various industrial applications. The standard sets requirements for material grades, chemical composition, mechanical properties, dimensions, and delivery conditions to ensure the quality and suitability of the hydraulic steel tubes for their intended use.

EN10216-5 Hydraulic Steel Tube Grade:

Various grades of stainless steel, including:

- X2CrNi18-9 (1.4307)

- X6CrNiTi18-10 (1.4541)

- X6CrNiMoTi17-12-2 (1.4571)

- X2CrNiMo17-12-2 (1.4404)

- X5CrNiMo17-12-2 (1.4401)

- X6CrNiMoTi17-12-2 (1.4571)

EN10216-5 Hydraulic Steel Tube Chemical Composition:

The chemical composition varies depending on the specific material grade. Here is a general overview of the chemical composition for some commonly used grades:

|

Grade |

1.4307 |

1.4541 |

1.4571 |

1.4404 |

1.4401 |

1.4571 |

|

C |

≤0.030 |

≤0.08 |

≤0.08 |

≤0.030 |

≤0.07 |

≤0.08 |

|

Si |

≤1.00 |

≤1.00 |

≤1.00 |

≤1.00 |

≤1.00 |

≤1.00 |

|

Mn |

≤2.00 |

≤2.00 |

≤2.00 |

≤2.00 |

≤2.00 |

≤2.00 |

|

P |

≤0.045 |

≤0.045 |

≤0.045 |

≤0.045 |

≤0.045 |

≤0.045 |

|

S |

≤0.015 |

≤0.015 |

≤0.015 |

≤0.015 |

≤0.015 |

≤0.015 |

|

Cr |

17.0-19.5 |

17.0-19.0 |

16.5-18.5 |

16.5-18.5 |

16.5-18.5 |

16.5-18.5 |

|

Ni |

8.0-10.5 |

9.0-12.0 |

9.0-12.0 |

10.0-13.0 |

10.0-13.0 |

9.0-12.0 |

|

Mo |

- |

- |

2.0-3.0 |

2.0-2.5 |

2.0-2.5 |

2.0-3.0 |

|

Ti |

- |

≥5Cmin |

≥5Cmin |

- |

- |

≥5Cmin |

Note: C represents the carbon content.

EN10216-5 Hydraulic Steel Tube Mechanical Properties:

The mechanical properties vary depending on the specific material grade. Here is a general overview of the mechanical properties for some commonly used grades:

|

Grade |

Tensile Strength (MPa) |

Yield Strength (MPa) |

Elongation (%) |

Hardness (HB) |

|

1.4307 |

≥500 |

≥200 |

≥35 |

≤215 |

|

1.4541 |

≥500 |

≥220 |

≥35 |

≤215 |

|

1.4571 |

≥500 |

≥210 |

≥35 |

≤215 |

|

1.4404 |

≥520 |

≥210 |

≥35 |

≤215 |

|

1.4401 |

≥520 |

≥220 |

≥35 |

≤215 |

|

1.4571 |

≥520 |

≥210 |

≥35 |

≤215 |

EN10216-5 Hydraulic Steel Tube Delivery Condition:

Tubes are delivered in the solution-annealed condition.

|

Symbol b |

Type of delivery condition |

Surface condition |

|

HFD |

Hot finished heat treated, descaled |

Metallically clean |

|

CFD |

Cold finished heat treated, descaled |

Metallically clean |

|

CFA |

Cold finished bright annealed |

Metallically bright |

|

CFG |

Cold finished heat treated, ground |

Metallically bright-ground, the type and degree of roughness shall be agreed at the time of enquiry and order c |

|

CFP |

Cold finished heat treated, polished |

Metallically bright-polished, the type and degree of roughness shall be agreed at the time of enquiry and order c |

|

a Combinations of the different conditions may be agreed at the time of enquiry and order. b The symbols are abbreviations for type of condition. Example: CFD = Cold Finished Descaled. c The enquiry and the order shall indicate whether the roughness requirement applies on the internal or external tube surface, or internal and external. |

||

EN10216-5 Hydraulic Steel Tube Permissible Variations in Dimensions:

The permissible variations in dimensions depend on the specific requirements outlined in EN 10216-5 and the applicable manufacturing standards. It includes tolerances for outer diameter, wall thickness, length, and straightness.

|

Tolerances on D ≤ 219,1 mm |

Tolerances on T |

||

|

Tolerance class |

Permissible deviation |

Tolerance class |

Permissible deviation |

|

D3 |

± 0,75 % or ± 0,3 mm whichever is the greater |

T3 |

± 10 % or ± 0,2 mm whichever is the greater |

|

D4a |

± 0,5 % or ± 0,1 mm whichever is the greater |

T4a |

± 7,5 % or ± 0,15 mm whichever is the greater |

EN10216-5 Hydraulic Steel Tube Advantages:

EN 10216-5 hydraulic steel tubes offer several advantages, including:

- High corrosion resistance

- Excellent mechanical properties

- Suitable for high-pressure applications

- Seamless construction ensures smooth flow and minimal pressure loss

EN10216-5 Hydraulic Steel Tube Applications:

EN 10216-5 hydraulic steel tubes are commonly used in various industries, including:

- Hydraulic and pneumatic systems

- Chemical and petrochemical industry

- Power generation

- Process piping

- Instrumentation

EN 10216-5 hydraulic tubes are seamless stainless steel tubes specifically designed and manufactured for use in hydraulic systems. These systems use fluid power to perform various functions, such as moving and controlling machinery. The tubes must have high strength, corrosion resistance, and durability to withstand the high pressures and mechanical stresses typically found in hydraulic applications.

EN10216-5 Hydraulic Steel Tube

-

-

Small-Diameter Heavy-Wall Tube|Heavy-Wall Tubing

VIEW MORE+ -

Super Austenitic 904L tubes|Super Austenitic 904L precision tubes

VIEW MORE+

请输入搜索关键字

确定