What is Drawn Over Mandrel (DOM) tubing?

What is Drawn Over Mandrel (DOM) tubing?

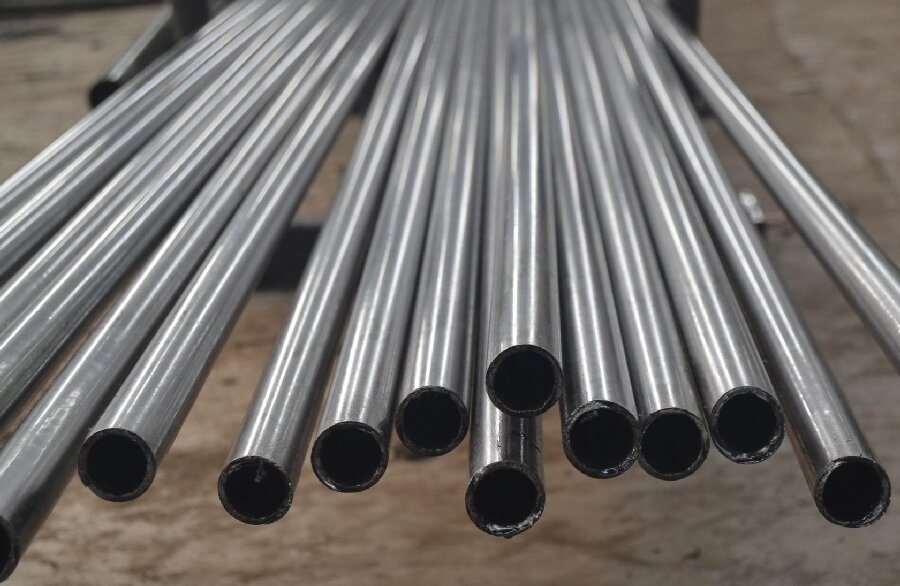

Drawn Over Mandrel (DOM) tubing is a type of high-quality steel tube that is manufactured using a cold drawing process over a mandrel, resulting in superior dimensional accuracy, surface finish, and mechanical properties compared to other tubing methods. The process begins with a mother tube, which is cold drawn through a die and over a mandrel, a technique that eliminates the weld seam and enhances the tubes concentricity and uniformity. DOM tubing is highly regarded for its strength, smooth interior and exterior surfaces, and tight tolerances, making it an ideal choice for applications requiring precision, such as hydraulic cylinders, automotive components, and mechanical structures. The absence of a weld seam also contributes to its increased tensile strength and structural integrity, positioning DOM tubing as a premium option in industries demanding high performance and reliability.

Drawn Over Mandrel (DOM) Tubing Manufacturing Process

1. Initial Tube Production:

The process begins with a hot-rolled steel strip which is formed into a tube shape through a series of rollers.

The tube is then welded longitudinally to form a welded tube.

2. Cold Drawing:

The welded tube is cleaned and treated to remove any surface impurities.

It is then drawn through a die and over a mandrel (a rod-like tool) under high pressure. This step is known as cold drawing.

3. Precision and Finishing:

The cold drawing process reduces the diameter and wall thickness while improving the mechanical properties and surface finish of the tube.

After drawing, the tube is often heat-treated (annealed) to relieve stresses and improve ductility.

Characteristics of DOM Tubing

High Strength: The cold drawing process enhances the tensile strength of the tubing.

Dimensional Accuracy: DOM tubes have tight tolerances on the outside diameter (OD) and inside diameter (ID), making them suitable for applications requiring high precision.

Smooth Surface: The internal surface of DOM tubing is smooth and free of welding flash, which is beneficial for applications involving hydraulic cylinders or other uses where internal smoothness is critical.

Consistency: The uniformity in wall thickness and the absence of weld seam makes DOM tubing more consistent in mechanical properties compared to welded tubes.

Drawn Over Mandrel (DOM) Tubing Applications

Automotive Industry: Used in drive shafts, steering columns, and suspension components due to its strength and precision.

Hydraulics and Pneumatics: Ideal for hydraulic cylinders and pneumatic actuators, where smooth internal surfaces and dimensional accuracy are crucial.

Construction and Structural Components: Employed in construction for frameworks, supports, and other structural elements requiring reliability and strength.

Machinery and Equipment: Used in various types of machinery, agricultural equipment, and industrial tools.

Drawn Over Mandrel (DOM) Tubing Advantages

Enhanced Mechanical Properties: The cold drawing process improves the strength and hardness of the steel.

Superior Surface Finish: Both the exterior and interior surfaces of DOM tubing are smoother compared to other types of tubing.

Greater Durability: The uniformity and consistency make it more durable under stress and less prone to failure.

Drawn Over Mandrel (DOM) Tubing Comparison with Other Tubing

ERW (Electric Resistance Welded) Tubing: Unlike ERW, which has a visible seam, DOM tubing has no visible seam due to the drawing process, resulting in a stronger and more aesthetically pleasing product.

Seamless Tubing: While seamless tubing is also strong and smooth, DOM tubing is often preferred for applications requiring tight tolerances and high precision due to its manufacturing process.

Drawn Over Mandrel (DOM) Tube

请输入搜索关键字

确定