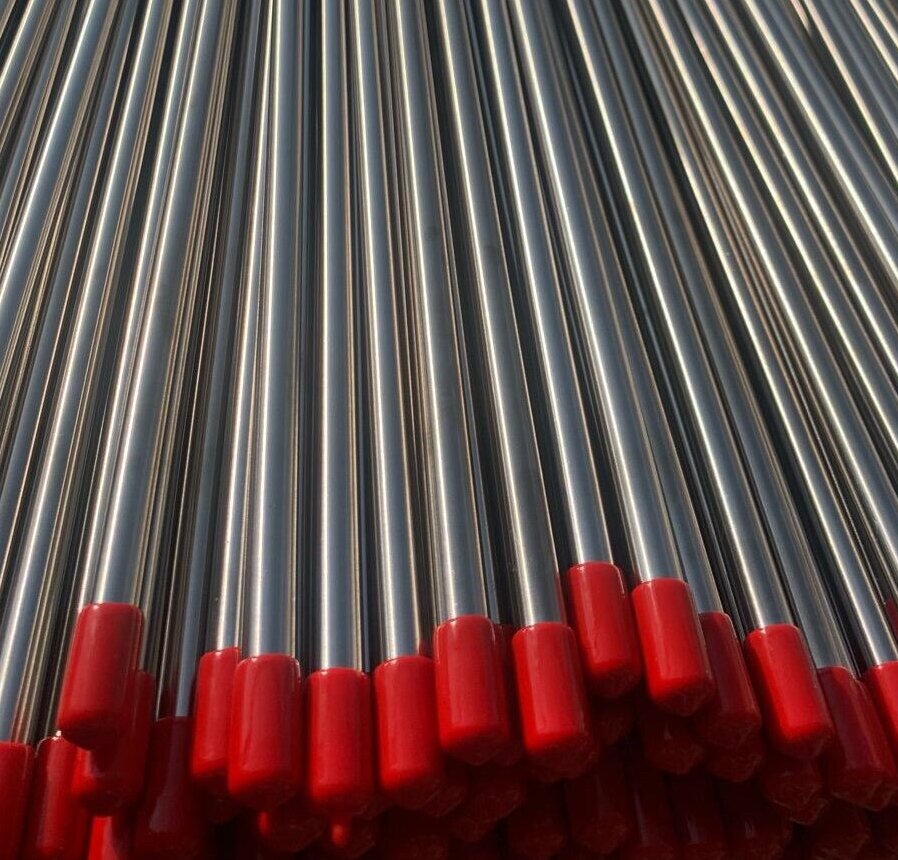

Food-grade stainless steel hydraulic tubing

What is food-grade stainless steel hydraulic tubing?

Food-grade stainless steel hydraulic tubing is a type of hydraulic piping used in industries such as food, beverage, and pharmaceuticals. It is made from stainless steel, offering the advantages of corrosion resistance and compliance with food safety standards. This hydraulic tubing ensures the safe transfer of food or pharmaceutical substances in hydraulic systems, avoiding the introduction of any harmful substances or contamination. Additionally, it can withstand high temperatures and corrosive environments, making it suitable for various food processing applications.

Features and advantages of food-grade stainless steel hydraulic tubing:

1. Material Excellence:

- Stainless steel typically contains at least 10.5% chromium, which forms a protective oxide layer on the surface, providing corrosion resistance.

- The chromium content can range from 10.5% to 30%, with higher percentages correlating with greater corrosion resistance.

2. High-Temperature Endurance:

- Food-grade stainless steel, such as type 316, can withstand temperatures ranging from -150°C to over 800°C, making it suitable for various food processing applications, including high-temperature sterilization processes.

- The thermal conductivity of stainless steel is relatively low, which helps maintain its structural integrity even at high temperatures.

3. Safety Credentials:

- FDA approval ensures that materials meet strict safety standards for food contact materials in the United States.

- EC1935/2004 compliance indicates conformity with European Union regulations regarding materials and articles intended to come into contact with food.

4. Hygienic Design:

- The surface roughness of stainless steel tubing is typically measured in Ra (roughness average) units. Food-grade tubing often has a low Ra value, such as Ra ≤ 0.8 μm, to minimize surface imperfections and facilitate easy cleaning.

- Studies have shown that stainless steel surfaces with low Ra values exhibit reduced bacterial adhesion compared to other materials, enhancing hygiene.

5. Pressure Resilience:

- Stainless steel hydraulic tubing is available in various pressure ratings, with common pressure ranges including 1500 psi, 3000 psi, and 6000 psi.

- The burst pressure of stainless steel tubing can be several times higher than its maximum operating pressure, ensuring safety under extreme conditions.

6. Versatility and Adaptability:

- Stainless steel hydraulic tubing comes in a wide range of sizes, from small-diameter tubes with outer diameters as low as 1/16 inch (1.6 mm) to large-diameter pipes exceeding 12 inches (304.8 mm) in diameter.

- Different grades of stainless steel are available to meet specific requirements, including austenitic (e.g., 304, 316) and duplex stainless steels, offering flexibility for various applications.

7. Longevity and Cost-effectiveness:

- Stainless steel tubing has a long service life, with an estimated lifespan of 20 to 50 years or more, depending on environmental conditions and maintenance practices.

- While the initial cost of stainless steel tubing may be higher than other materials such as carbon steel or plastic, its durability, low maintenance requirements, and resistance to corrosion contribute to long-term cost savings.

Main difference between food-grade sanitary tubes and ordinary stainless steel tubes

The main difference between food-grade sanitary tubes and ordinary stainless steel tubes is that the former undergo internal surface polishing. This reduces resistance and increases fluidity during fluid transmission, preventing stainless steel debris from being dislodged by fluid impact, and minimizing the buildup of deposits on the inner wall of the pipe, ensuring hygiene and safety. Additionally, food-grade sanitary pipes are characterized by high precision, excellent surface finish, uniform wall thickness, corrosion resistance, and temperature resistance. They are commonly used in pharmaceutical, food, beverage, and brewery industries where strict safety requirements are essential.

Product Features: In fields such as biopharmaceuticals, food production, and clean gas installation, there are stringent requirements for the cleanliness of stainless steel sanitary pipes. Food-grade sanitary pipes are cleaned using specialized detergents and ultrasonic circulation, ensuring they are dust-free and oil-free for safe use.

Food-grade stainless steel hydraulic tubing

请输入搜索关键字

确定