Cold Drawn Seamless (CDS) Steel Tube vs. Drawn Over Mandrel (DOM) Steel Tube

The comparison between Cold Drawn Seamless (CDS) Steel Tube and Drawn Over Mandrel (DOM) Steel Tube, including their advantages and disadvantages.

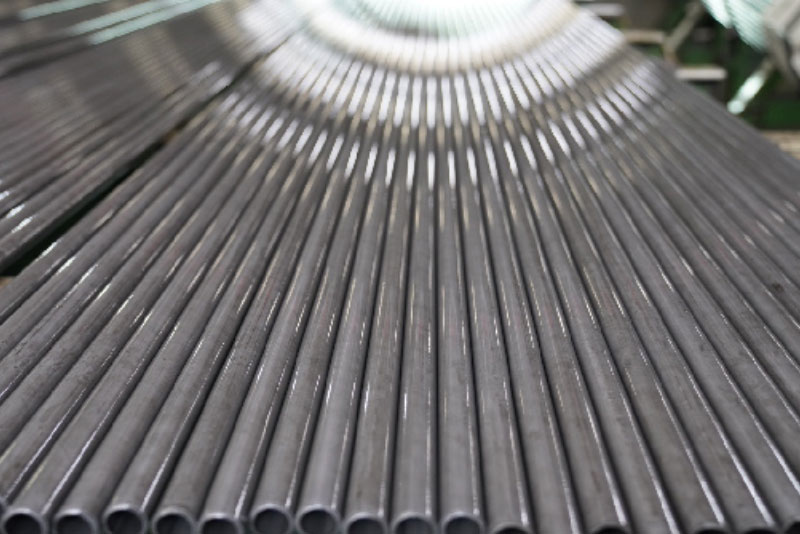

CDS Steel Tube short for Cold Drawn Seamless (CDS) Tub

DOM Steel Tube short for Drawn Over Mandrel (DOM) Steel Tube

Cold Drawn Seamless (CDS) Steel Tubes and Drawn Over Mandrel (DOM) Steel Tubes are two common types of precision steel tubing used in various industries, including automotive, construction, and machinery. While they share some similarities in their manufacturing processes, they also have distinct differences in terms of production and application.

CDS Steel Tube and DOM Steel Tube Manufacturing Process:

CDS Steel Tube:

- CDS Steel Tubes are created through a cold drawing process where a solid steel bar is pulled through a die to reduce its diameter and thickness.

- This method produces a smooth and uniform Steel Tube with consistent wall thickness.

DOM Steel Tube:

- DOM Steel Tubes begin as electric resistance welded (ERW) Steel Tubes. ERW Steel Tubes are initially formed by welding a sheet or strip of steel into a cylindrical shape.

- After the ERW step, DOM Steel Tubes go through a mandrel-drawing process. This involves passing the Steel Tube through a mandrel (a tapered rod or plug) to further enhance dimensional accuracy and surface finish.

CDS Steel Tube and DOM Steel Tube Advantages:

CDS Steel Tube:

- Cost-Effective: CDS Steel Tubes are generally more cost-effective to produce since they undergo fewer manufacturing steps.

- Versatile: Suitable for various applications, including structural components and hydraulic cylinders.

DOM Steel Tube:

- Superior Surface Finish: DOM Steel Tubes have a smoother and more consistent surface finish due to the mandrel-drawing process. Ideal for applications where a high-quality finish is crucial.

- Exceptional Dimensional Accuracy: DOM Steel Tubes are known for their precise dimensions, making them suitable for applications requiring tight tolerances.

- Increased Strength: Both CDS and DOM Steel Tubes offer excellent strength and durability, but DOM Steel Tubes, with their enhanced surface quality, may exhibit slightly improved performance.

CDS Steel Tube and DOM Steel Tube Disadvantages:

CDS Steel Tube:

- Surface Finish Variability: The surface finish of CDS Steel Tubes can vary depending on the manufacturer and application requirements.

DOM Steel Tube:

- Higher Cost: DOM Steel Tubes are typically more expensive to produce due to the additional mandrel-drawing step.

- Limited Availability: DOM Steel Tubes may not be as readily available as CDS Steel Tubes, especially for non-standard sizes or grades.

CDS Steel Tube and DOM Steel Tube Applications:

CDS Steel Tube:

- CDS Steel Tubes find applications in a wide range of industries, including structural components, automotive parts, and general machinery.

DOM Steel Tube:

- DOM Steel Tubes are preferred for precision applications such as hydraulic cylinders, shock absorber Steel Tubes, and situations where a smooth surface finish and tight tolerances are essential.

In conclusion, both CDS and DOM Steel Tubes have their own sets of advantages and disadvantages. CDS Steel Tubes are cost-effective and versatile, while DOM Steel Tubes excel in terms of surface finish and dimensional accuracy. The choice between the two depends on specific project requirements, budget considerations, and the desired level of precision and surface quality.

Cold Drawn Seamless (CDS) Steel Tube

请输入搜索关键字

确定