What is DOM tubing?

Specifically designed for use in mechanical machinery and buildings, mechanical tubing is a type of steel pipe. It has excellent mechanical qualities and strength, and it is commonly used to manufacture mechanical parts and construct mechanical structures. Mechanical tubings are classified into many varieties based on their manufacturing technique. DOM tubing is one of such. It is a high-end type of mechanical steel pipe that is ideal for applications requiring extreme dimensional accuracy and mechanical performance.

↓

|

Steel Grade |

C |

Mn |

P |

S |

|

1020 |

0.18-0.23 |

0.30-0.60 |

≤0.035 |

≤0.035 |

|

1026 |

0.22-0.28 |

0.60-0.90 |

≤0.035 |

≤0.035 |

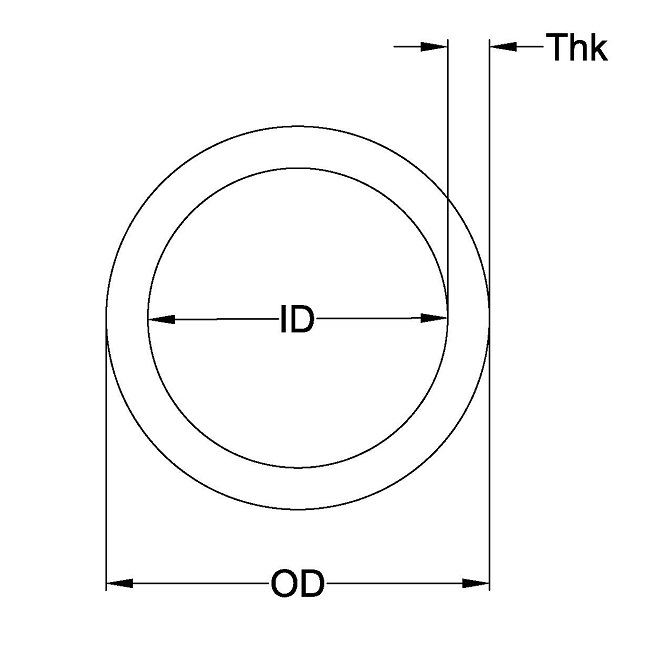

DOM Tubing Size

|

|

WT |

|||||||||||||||||

|

OD |

1.2 |

1.3 |

1.4 |

1.5 |

1.6 |

1.8 |

2 |

2.1 |

2.3 |

2.5 |

2.6 |

2.8 |

3 |

3.2 |

3.3 |

3.5 |

3.6 |

8.6 |

|

16 |

√ |

√ |

√ |

√ |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

18 |

√ |

√ |

√ |

√ |

√ |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

23 |

√ |

√ |

√ |

√ |

√ |

√ |

|

|

|

|

|

|

|

|

|

|

|

|

|

25 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|

|

|

|

|

|

|

|

|

|

|

|

27.4 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|

|

|

|

|

|

|

|

|

|

|

32.4 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|

|

|

|

|

|

|

|

|

|

37.4 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|

|

|

|

|

|

|

|

|

43 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|

|

|

|

|

|

|

|

45 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|

|

|

|

|

|

|

50.8 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|

|

|

|

|

|

54 |

|

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|

|

|

|

|

|

56 |

|

|

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|

|

|

|

|

|

60 |

|

|

|

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|

|

|

|

|

63.5 |

|

|

|

|

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|

|

|

|

65 |

|

|

|

|

|

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|

|

|

|

68 |

|

|

|

|

|

|

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|

|

|

70 |

|

|

|

|

|

|

|

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|

73 |

|

|

|

|

|

|

|

|

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|

75 |

|

|

|

|

|

|

|

|

|

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|

OD Range |

Tolerance |

||||

|

Outside Diameter |

Inside Diameter |

||||

|

in. |

mm |

in. |

mm |

in. |

mm |

|

0.394-0.499 |

10-12.67 |

+0.004/-0 |

+0.1/-0 |

- |

- |

|

0.500-1.699 |

12.7-43.15 |

+0.005/-0 |

+0.13/-0 |

+0/-0.005 |

+0/-0.13 |

|

1.700-2.099 |

43.18-53.31 |

+0.006/-0 |

+0.15/-0 |

+0/-0.006 |

+0/-0.15 |

|

2.100-2.499 |

53.34-63.47 |

+0.007/-0 |

+0.18/-0 |

+0/-0.007 |

+0/-0.18 |

|

2.500-2.899 |

63.5-73.63 |

+0.008/-0 |

+0.2/-0 |

+0/-0.008 |

+0/-0.2 |

|

2.900-3.299 |

73.66-83.79 |

+0.009/-0 |

+0.23/-0 |

+0/-0.009 |

+0/-0.23 |

|

3.300-3.699 |

83.82-93.95 |

+0.010/-0 |

+0.25/-0 |

+0/-0.010 |

+0/-0.25 |

|

3.700-4.099 |

93.98-104.11 |

+0.011/-0 |

+0.28/-0 |

+0/-0.011 |

+0/-0.28 |

|

4.100-4.499 |

104.14-114.27 |

+0.012/-0 |

+0.3/-0 |

+0/-0.012 |

+0/-0.3 |

|

4.500-4.899 |

114.30-124.43 |

+0.013/-0 |

+0.33/-0 |

+0/-0.013 |

+0/-0.33 |

|

Wall Thickness (mm) |

OD Size (mm) |

|||

|

10≤OD≤20 |

20<OD≤50 |

50<OD≤100 |

100<OD≤120 |

|

|

1.24 |

+0.05/-0.05 |

+0.05/-0.08 |

+0.05/-0.08 |

- |

|

1.65 |

+0.05/-0.05 |

+0.05/-0.08 |

+0.05/-0.08 |

+0.1/-0.1 |

|

2.11 |

+0.05/-0.05 |

+0.05/-0.08 |

+0.08/-0.08 |

+0.1/-0.13 |

|

2.41 |

+0.05/-0.05 |

+0.05/-0.08 |

+0.08/-0.08 |

+0.1/-0.13 |

|

2.77 |

+0.05/-0.08 |

+0.05/-0.1 |

+0.08/-0.08 |

+0.13/-0.13 |

|

3.05 |

+0.08/-0.08 |

+0.05/-0.1 |

+0.08/-0.08 |

+0.13/-0.13 |

|

3.4 |

- |

+0.05/-0.1 |

+0.08/-0.08 |

+0.13/-0.13 |

|

3.76 |

- |

+0.05/-0.1 |

+0.08/-0.08 |

+0.13/-0.13 |

|

4.19 |

- |

+0.08/-0.1 |

+0.08/-0.1 |

+0.13/-0.15 |

|

4.57 |

- |

+0.1/-0.1 |

+0.08/-0.13 |

+0.15/-0.15 |

|

5.16 |

- |

+0.1/-0.13 |

+0.1/-0.13 |

+0.15/-0.18 |

|

5.59 |

- |

+0.1/-0.15 |

+0.1/-0.15 |

+0.18/-0.18 |

|

6.05 |

- |

+0.13/-0.15 |

+0.13/-0.15 |

+0.18/-0.18 |

|

6.58 |

- |

+0.13/-0.15 |

+0.13/-0.13 |

+0.18/-0.18 |

|

7.21 |

- |

+0.13/-0.15 |

+0.13/-0.15 |

+0.18/-0.18 |

|

7.62 |

- |

+0.15/-0.15 |

+0.15/-0.15 |

+0.2/-0.2 |

|

8.13 |

- |

+0.18/-0.18 |

+0.18/-0.18 |

+0.2/-0.2 |

|

8.74 |

- |

+0.2/-0.2 |

+0.2/-0.2 |

+0.23/-0.23 |

|

9.53 |

- |

- |

+0.23/-0.23 |

+0.23/-0.23 |

|

10.16 |

- |

- |

+0.25/-0.25 |

+0.25/-0.25 |

|

11.13 |

- |

- |

+0.28/-0.28 |

+0.28/-0.28 |

|

11.68 |

- |

- |

+0.3/-0.3 |

+0.3/-0.3 |

|

12.19 |

- |

- |

+0.3/-0.3 |

+0.3/-0.3 |

|

13.49 |

- |

- |

+0.33/-0.33 |

+0.33/-0.33 |

|

14.3 |

- |

- |

+0.33/-0.33 |

+0.33/-0.33 |

|

14.73 |

- |

- |

+0.36/-0.36 |

+0.36/-0.36 |

|

15.24 |

- |

- |

+0.38/-0.38 |

+0.38/-0.38 |

|

15.88 |

- |

- |

+0.41/-0.41 |

+0.41/-0.016 |

|

16.51 |

- |

- |

+0.43/-0.43 |

+0.43/-0.43 |

- PREV:What is CDS Tubing?

- NEXT:What is hydraulic line?

请输入搜索关键字

确定