NEWS CENTER

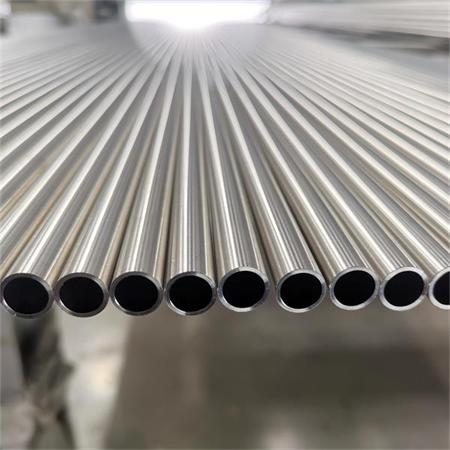

Pressure-tested hydraulic tubing

What is Pressure-tested hydraulic tubing?

Pressure-tested hydraulic tubing refers to tubing that has undergone rigorous testing to ensure its ability to withstand high-pressure conditions within hydraulic systems. Hydraulic tubing is a crucial component in hydraulic systems, which use fluids to transmit power. These systems are widely used in various industries, including manufacturing, construction, aerospace, and more.

Pressure testing is conducted to ensure the tubings integrity and reliability under the stress of high-pressure environments. The testing process typically involves subjecting the tubing to pressures that exceed the maximum working pressure it is expected to encounter in normal operating conditions. The goal is to verify that the tubing can withstand these pressures without experiencing failure or leaks.

Feature of pressure testing hydraulic tubing include:

1. Hydrostatic Testing: This is a common method for pressure testing hydraulic tubing. During hydrostatic testing, the tubing is filled with water or another suitable fluid, and pressure is gradually increased to a level that exceeds the maximum operating pressure. The tubing is inspected for any signs of leakage, distortion, or other defects.

2. Test Standards: Pressure testing is often conducted in accordance with industry standards and specifications, such as those set by organizations like the International Organization for Standardization (ISO), the American Society of Mechanical Engineers (ASME), or other relevant standards bodies.

3. Acceptance Criteria: The tubing must meet specific acceptance criteria to pass the pressure test. This includes factors such as no visible leakage, no permanent deformation, and maintaining structural integrity under the applied pressure.

4. Documentation: Results of the pressure testing, including pressure levels applied and any observations or issues noted during testing, are documented. This documentation is essential for quality control and compliance purposes.

5. Material and Design Considerations: The material composition and design of the hydraulic tubing play a crucial role in determining its ability to withstand pressure. Tubing materials must be selected based on factors like strength, corrosion resistance, and compatibility with hydraulic fluids.

Pressure-tested hydraulic tubing is crucial for ensuring the safety and reliability of hydraulic systems. It helps prevent the risk of hydraulic fluid leaks, which can lead to system failure, environmental hazards, and safety issues. Manufacturers and users of hydraulic systems must adhere to industry standards and conduct regular testing to ensure the ongoing integrity of hydraulic tubing in various applications.

Pressure-tested hydraulic tubings

请输入搜索关键字

确定