ASTM A513 Grade 1010 Mechanical Steel Tubing

ASTM A513 Grade 1010 Mechanical Steel Tubing

ASTM A513 Grade 1010 mechanical steel tubing is a versatile, low-carbon steel known for its excellent weldability, formability, and moderate strength. It is produced through electric resistance welding (ERW) and is available in various shapes and sizes, making it ideal for automotive parts, furniture, construction, and machinery. This tubing offers good corrosion resistance and uniform mechanical properties, ensuring durability and reliability across different applications. ASTM A513 Grade 1010 is a carbon steel tubing used in various mechanical applications due to its excellent weldability and moderate strength.

ASTM A513 Grade 1010 Mechanical Steel Tubing Specifications

- Standard: ASTM A513/ASME SA513

- Grade: 1010

- Dimensions: OD 6.35mm-305mm, Wall Thickness 0.56mm-3.4mm

- Form: Round, square, rectangular

ASTM A513 Grade 1010 Mechanical Steel Tubing Chemical Composition

- Carbon: 0.08-0.13%

- Manganese: 0.30-0.60%

- Phosphorus: max 0.035%

- Sulfur: max 0.035%

|

Element |

Composition (Weight %) |

|

Carbon (C) |

0.08 - 0.13 |

|

Manganese (Mn) |

0.30 - 0.60 |

|

Phosphorus (P) |

≤ 0.035 |

|

Sulfur (S) |

≤ 0.035 |

ASTM A513 Grade 1010 Mechanical Steel Tubing Mechanical Properties

- Tensile Strength: 45,000 psi (310 MPa)

- Yield Strength: 25,000 psi (170 MPa)

- Elongation: 20% in 2 inches

|

Property |

Value |

|

Tensile Strength |

45,000 psi (310 MPa) |

|

Yield Strength |

25,000 psi (170 MPa) |

|

Elongation (in 2 inches) |

15-30% |

|

Hardness (Rockwell B) |

55 |

ASTM A513 Grade 1010 Mechanical Steel Tubing Manufacturing Process

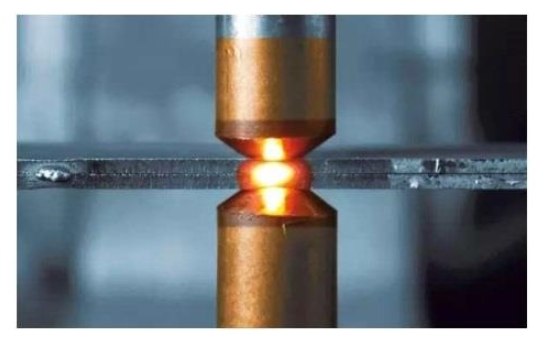

Electric resistance welding (ERW) involves forming steel strips into the desired shape and welding the edges using electric resistance. This method ensures high productivity and minimal deformation.

ASTM A513 Grade 1010 Mechanical Steel Tubing Features

- Weldability: Superb, suitable for various welding methods.

- Formability: Excellent, allowing for easy shaping and fabrication.

- Strength: Moderate, suitable for various structural applications.

- Corrosion Resistance: Good, enhancing durability and longevity.

ASTM A513 Grade 1010 Mechanical Steel Tubing Applications

- Automotive: Ideal for exhaust systems, chassis components.

- Furniture: Used in frames and structural parts.

- Construction: Suitable for columns, beams, and other load-bearing structures.

- Machinery: Used in conveyor systems, agricultural machinery, and other equipment.

ASTM A513 Grade 1010 Mechanical Steel Tubing Advantages

- Versatility: Applicable in numerous industries due to its properties.

- Cost-Effective: Affordable material with excellent performance characteristics.

- Availability: Readily available in various shapes and sizes.

Electric Resistance Welding Process

请输入搜索关键字

确定