NEWS CENTER

Precision Hydraulic Steel Tube Production Standards

Precision Hydraulic Steel Tube Main Production Standards and Technical Requirements:

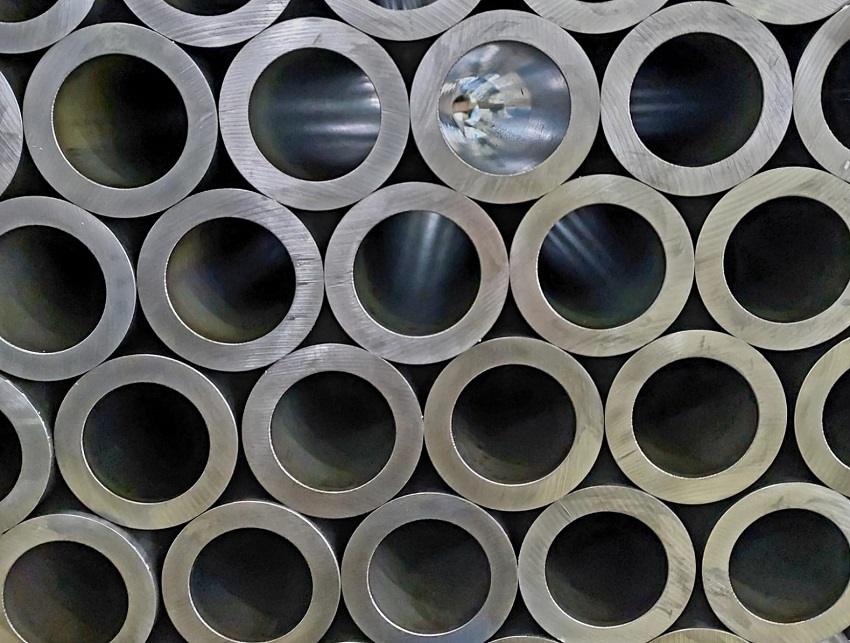

Precision hydraulic steel tubes are manufactured to meet stringent production standards, ensuring high performance and reliability in demanding applications. The main production standards typically include DIN 2391, EN 10305-4, and ASTM A519, which specify the requirements for dimensional accuracy, mechanical properties, and surface quality. These tubes are produced through processes such as cold drawing and precision rolling to achieve tight tolerances, superior surface finish, and enhanced strength. Technical requirements often involve strict controls on chemical composition, microstructure, and testing protocols like non-destructive testing, pressure testing, and dimensional inspections to ensure the tubes meet the required specifications for hydraulic systems, where high pressure and fluid control are critical.

European Union Primary Tube Production Standards:

- EN 10305-1: Precision Hydraulic Steel Tube, Technical Delivery Conditions, Part 1: Cold Drawn Seamless Steel Tube

- EN 10305-2: Precision Hydraulic Steel Tube, Technical Delivery Conditions, Part 2: Cold Drawn Welded Steel Tube

- EN 10305-3: Precision Hydraulic Steel Tube, Technical Delivery Conditions, Part 3: Welded Steel Tube

- EN 10305-4: Precision Hydraulic Steel Tube, Technical Delivery Conditions, Part 4: Cold Drawn Seamless Steel Tube for Hydraulic and Pneumatic Systems

- EN 10305-5: Precision Hydraulic Steel Tube, Technical Delivery Conditions, Part 5: Welded Square and Rectangular Steel Tube

- EN 10305-6: Precision Hydraulic Steel Tube, Technical Delivery Conditions, Part 6: Cold Drawn Welded Steel Tube for Hydraulic and Pneumatic Systems

Chinas Main Standards for Precision Hydraulic Steel Tube:

- GB/T 3639: Cold Drawn or Cold Rolled Precision Seamless Steel Tube

- GB 8713: Precision Inner Diameter Seamless Steel Tube for Hydraulic and Pneumatic Cylinder

- GB/T 14975: Stainless Steel Seamless Steel Tube for Structures

Main Standards for Precision Hydraulic Steel Tube in the United States:

- ASTM A519: Seamless Carbon and Alloy Steel Mechanical Tubing

- ASTM A500: Structural Carbon Steel Cold-Formed Circular Section and Shape Welded and Seamless Steel Tubes

- AS 1450: Steel Tubes for Mechanical Purposes

- ASME B36.10M: Welded and Seamless Wrought Steel Pipe, Technical Delivery Conditions

- ASME B36.19M: Stainless Steel Pipe, Technical Delivery Conditions

- SAE J512: Automotive Tube Fittings

- SAE J525: Welded and Cold Drawn Low-Carbon Steel Tubing Annealed for Bending and Flaring

- SAE J526: Welded Low-Carbon Steel Tubing

- SAE J435: Automotive Steel Castings

- SAE J2467: Welded and Cold-Drawn, SAE 1021 Carbon Steel Tubing Normalized for Bending and Flaring

Main Standards for Precision Hydraulic Steel Tube in the United Kingdom:

- BS 6323-1 to BS 6323-8: Seamless and Welded Steel Tubes for Automobile, Mechanical, and General Engineering Purposes

- IS 3074: Steel Tube for Automotive Purpose

Main Standards for Precision Hydraulic Steel Tube in Germany:

- DIN 2391-1: Cold Rolled or Cold Drawn Precision Seamless Steel Tube, Dimensional Requirements

- DIN 2391-2: Cold Rolled or Cold Drawn Precision Seamless Steel Tube, Technical Delivery Conditions

- DIN 2393-1: Cold Rolled or Cold Drawn Precision Welded Steel Tube, Dimensional Requirements

- DIN 2393-2: Cold Rolled or Cold Drawn Precision Welded Steel Tube, Technical Delivery Conditions

Main Standards for Precision Hydraulic Steel Tube in Russia:

- GOST 8733: Cold Rolled Cold Deformation and Hot Rolled Hot Deformation Seamless Steel Tube Technical Delivery Conditions

- GOST 8734: Cold Rolled or Cold Drawn Seamless Steel Tube Technical Delivery Conditions

Main Standards for Precision Hydraulic Steel Tube in Japan:

- JIS G3441: Alloy Steel Tubes for Mechanical Structures, Technical Delivery Conditions

- JIS G3445: Carbon Steel Tubes for Mechanical Structures, Technical Delivery Conditions

- JIS G3446: Stainless Steel Tubes for Mechanical Structures, Technical Delivery Conditions

- JIS G3459: Stainless Steel Pipes, Technical Delivery Conditions

- JIS G3466: Carbon Steel Square Tubes for General Structure, Technical Delivery Conditions

- JIS G3472: Carbon Steel Tubes for Automobile Structural Purposes, Technical Delivery Conditions

- JIS G3473: Carbon Steel Tubes for Cylinder Barrels, Technical Delivery Conditions

- JIS G4903: Nickel-Chromium-Iron Alloy Seamless Pipes, Technical Delivery Conditions

Main Standards for Precision Hydraulic Steel Tube in France:

- NF A49-541: Steel Tubes Cold Finished Welded Structural Hollow Sections

- NF A49-501: Steel Tubes Seamless or Welded Hot Finished Structural Hollow Sections

- NF A49-341: Steel Tubes Precision Welded Tubes for Mechanical Application

- NF A49-330: Steel Tubes Seamless Cold Drawn Tubes for Hydraulic and Pneumatic Power Systems

- NF A49-327: Steel Tubes Jack for Pneumatic Transmissions Cold Drawn Seamless Tubes Type Ready for Use

- NF A49-323: Steel Tubes Jacks for Hydraulic Transmissions Cold Rolled or Cold Drawn Seamless Tubes Type Ready for Use

Precision Hydraulic Steel Tube Main Materials:

10#, 20#, 35#, 45#, 40Cr, 25Mn, 37Mn5, St35(E235), St37.4, St45(E255), St52(E355), 30CrMo, 42CrMo, 4130, 4140...

Precision Hydraulic Steel Tube Main Delivery Conditions:

NBK(+N), GBK(+A), BK(+C), BKW(+LC), BKS(+SR)

Precision Hydraulic Steel Tubes

请输入搜索关键字

确定