NEWS CENTER

What are steel hydraulic lines?

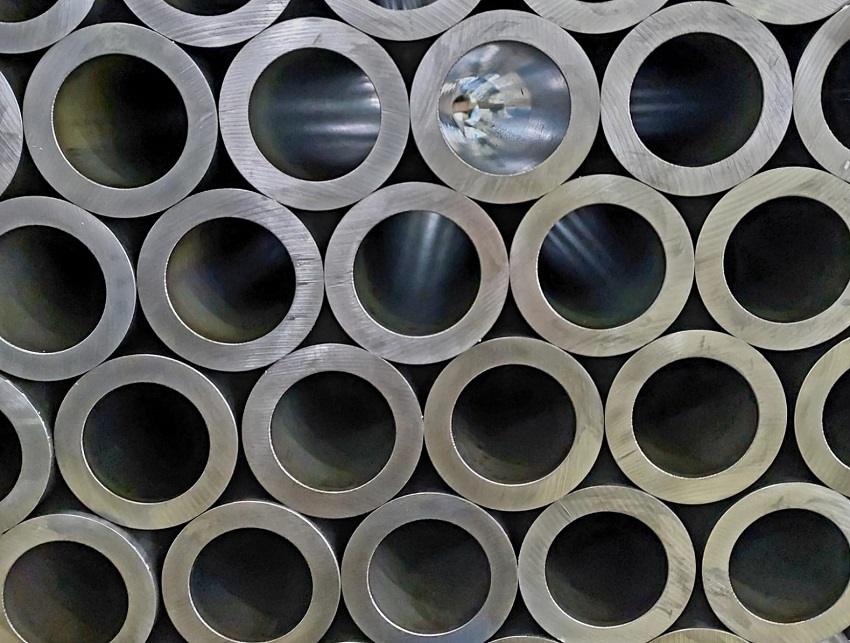

What are Steel Hydraulic Lines?

Steel hydraulic lines are tubes or pipes made of steel that are designed to convey hydraulic fluid under high pressure within hydraulic systems. These lines are essential components in various industrial and mobile applications, including construction machinery, agricultural equipment, manufacturing plants, and automotive systems.Steel hydraulic lines, also known as hydraulic tubing or hydraulic pipes, play a crucial role in hydraulic systems. These lines are used to transmit hydraulic fluid (usually oil) under high pressure to perform various functions in hydraulic machinery and equipment.

1. Steel Hydraulic Lines Material:

Steel hydraulic lines are typically made from materials that can withstand high pressure and provide durability. Common materials include carbon steel and stainless steel. Carbon steel is often used for general hydraulic applications, while stainless steel is chosen for its corrosion resistance in more demanding environments.

1.1. Carbon Steel

Characteristics:High strength and durability.Cost-effective and widely available.

Common Grades:

SAE J525: This grade is known for its seamless, low-carbon steel tubing. It is suitable for bending and flaring, making it ideal for hydraulic systems requiring precision.

SAE J524: Similar to J525, this grade offers seamless, low-carbon steel but is specifically designed for bending and forming applications. It maintains its properties under high pressure.

ASTM A179: This grade is a seamless cold-drawn low-carbon steel tube used in high-temperature and high-pressure applications. It offers excellent heat transfer properties, making it suitable for heat exchangers and condensers in hydraulic systems.

1.2. Stainless Steel

Characteristics:Exceptional corrosion resistance.High strength and excellent performance at extreme temperatures.

Common Grades:

304 Stainless Steel: Offers good corrosion resistance, formability, and weldability. It is a versatile grade used in various hydraulic applications where moderate corrosion resistance is required.

316 Stainless Steel: Contains molybdenum, which enhances its corrosion resistance, especially against chlorides and other industrial solvents. It is ideal for marine and chemical processing applications.

321 Stainless Steel: Stabilized with titanium, this grade provides excellent resistance to intergranular corrosion after exposure to high temperatures. It is used in high-temperature hydraulic systems.

1.3. Alloy Steel

Characteristics:Enhanced mechanical properties due to alloying elements.Superior strength and toughness.

Common Grades:

4130 Alloy Steel: Contains chromium and molybdenum, offering a good balance of strength, toughness, and wear resistance. It is often used in aerospace and heavy machinery applications where high stress is encountered.

4140 Alloy Steel: Similar to 4130 but with higher carbon content, offering greater hardness and strength. It is used in high-pressure hydraulic systems and industrial machinery.

2. Steel Hydraulic Lines Sizes and Dimensions:

Hydraulic lines come in various sizes and dimensions to accommodate different flow rates, pressure levels, and specific system requirements. The sizing is critical to ensure proper fluid flow and pressure within the hydraulic system.

3. Steel Hydraulic Lines Construction:

Hydraulic lines are constructed using various techniques, including seamless and welded methods. Seamless tubing is produced without any welding, providing uniform strength throughout the entire length. Welded tubing is created by welding together sections of steel.

4. Steel Hydraulic Lines Coating:

To enhance corrosion resistance and improve the lifespan of hydraulic lines, they are often coated with materials such as zinc or other corrosion-resistant coatings. This is especially important in applications where the hydraulic system may be exposed to harsh environmental conditions.

4.1. Phosphate Coating: A chemical treatment that creates a layer of phosphate crystals on the steel.

4.2. Zinc Plating: A process that applies a thin layer of zinc to the steel through electroplating.

4.3. Galvanizing: Dipping steel into molten zinc to form a thick, durable coating.

4.4. Polymer Coatings (e.g., Nylon, PTFE): Coatings made from plastics like nylon or PTFE, applied as a spray or dip.

4.5. Electroplating: Applying a thin layer of metal (like chromium or nickel) using an electric current.

4.6. Epoxy Coatings: A hard, protective layer applied as a liquid or powder and then cured.

5. Steel Hydraulic Lines Bending and Flexibility:

Steel hydraulic lines need to be flexible enough to accommodate the movement of hydraulic components while maintaining their structural integrity. Some hydraulic lines are designed with specific flexibility characteristics or are equipped with flexible connectors to allow for movement.

6. Steel Hydraulic Lines End Fittings:

Hydraulic lines have fittings at their ends that connect them to other components in the hydraulic system, such as pumps, valves, cylinders, and reservoirs. These fittings are typically made of steel or other materials that can handle the hydraulic fluid and pressure.

7. Steel Hydraulic Lines Installation and Maintenance:

Proper installation and regular maintenance are crucial for the optimal performance and longevity of hydraulic lines. Care should be taken to avoid sharp bends, kinks, or damage during installation. Regular inspections can help identify and address issues before they lead to system failure.

8. Steel Hydraulic Lines Application:

Steel hydraulic lines are essential components in various applications across multiple industries, providing reliable fluid conveyance under high pressure.

8.1. Construction Machinery: Steel hydraulic lines are widely used in construction equipment such as excavators, bulldozers, cranes, and loaders. They transmit hydraulic fluid to power hydraulic cylinders, motors, and other components, enabling the machinery to perform heavy lifting, digging, and material handling tasks efficiently.

8.2. Agricultural Equipment: In tractors, combines, harvesters, and other agricultural machinery, steel hydraulic lines deliver hydraulic fluid to systems that control implements, steering, braking, and other vital functions. This ensures precise control and efficient operation in various farming activities.

8.3. Automotive Industry: Hydraulic lines in vehicles, particularly in trucks, buses, and other heavy-duty vehicles, are used in braking systems, power steering systems, and transmission systems. Steel hydraulic lines provide the necessary durability and reliability to handle the pressures and temperatures encountered in these applications.

8.4. Manufacturing and Industrial Machinery: Steel hydraulic lines are crucial in manufacturing plants and industrial settings, where they are used in hydraulic presses, injection molding machines, metal forming equipment, and automated production lines. These lines ensure precise control of hydraulic actuators and motors, enabling efficient and reliable operation of machinery.

8.5. Aerospace: In the aerospace industry, steel hydraulic lines are used in aircraft hydraulic systems, which control landing gear, flaps, brakes, and other critical components. The high strength and reliability of steel hydraulic lines make them suitable for the demanding conditions of aerospace applications.

8.6. Mining Equipment: Mining machinery such as drills, loaders, and haul trucks rely on hydraulic systems to operate efficiently in harsh environments. Steel hydraulic lines provide the necessary strength and resistance to abrasion and corrosion, ensuring reliable fluid transmission under extreme conditions.

8.7. Marine Applications: In ships and offshore platforms, steel hydraulic lines are used in hydraulic systems that control winches, cranes, steering mechanisms, and other vital equipment. Their corrosion resistance and durability make them ideal for marine environments.

8.8. Railway Systems: Hydraulic systems in trains and railway maintenance equipment use steel hydraulic lines for braking, suspension, and other control systems. The high-pressure capabilities of these lines ensure safety and reliability in rail operations.

Steel hydraulic lines

请输入搜索关键字

确定