NEWS CENTER

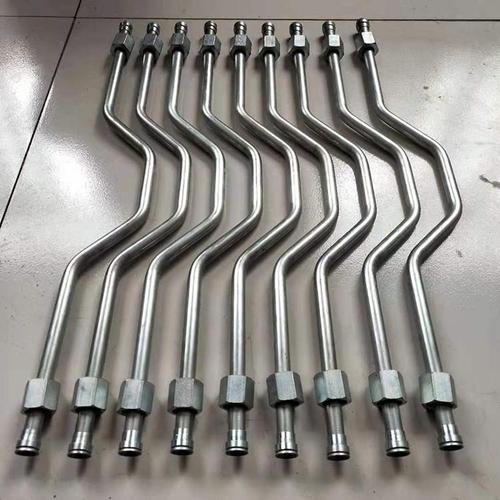

How to install and layout rigid hydraulic tube lines?

How to Install and Layout Rigid Hydraulic Tube Lines?

To install and layout rigid hydraulic tube lines effectively, start by carefully planning the route, considering factors like accessibility, potential obstructions, and stress points. Ensure the tubing is cut precisely to the required lengths and deburred to prevent damage to seals and fittings. Use appropriate bending tools to achieve smooth bends without kinking or flattening the tube. Secure the tubing firmly using clamps or brackets, maintaining proper clearance from moving parts or heat sources. Install fittings securely, following manufacturer specifications, and use appropriate sealing methods to prevent leaks. Finally, thoroughly test the system for leaks and proper functionality before putting it into operation. Regular inspection and maintenance are crucial to ensure continued performance and safety.

1. Selecting the Appropriate Hydraulic Tubes:

- Ensure the selection of suitable Hydraulic Tube materials, taking into account the conveyed fluid and working environment conditions.

- Determine the Hydraulic Tube diameter to meet the required flow and pressure specifications. Oversized or undersized Hydraulic Tubes can lead to issues.

2. Hydraulic Tube Length and Layout:

- Keep the Hydraulic Tube length as short as possible to reduce fluid resistance and energy losses.

- Avoid using too many 90° bends, as they increase fluid resistance. Its better to use two 45° bends instead of one 90° bend.

- When laying out Hydraulic Tubes, try to avoid a layout that is crisscrossed, cluttered, or congested to facilitate fault-finding, maintenance, and repairs.

3. Design of Bend Hydraulic Tubes:

- The radius of bend Hydraulic Tubes should be as large as possible, typically about 2.5 times the outer diameter of the rigid Hydraulic Tube.

- Leave straight Hydraulic Tube sections at both ends of a bend, with a length of at least two times the height of the Hydraulic Tube joint nut to ensure stable connections.

4. Hydraulic Tube Support and Fixation:

- Longer Hydraulic Tubes require the addition of Hydraulic Tube clamps for support, reducing mechanical vibration and noise.

- Use Hydraulic Tube clamps for fixation at both ends of bent Hydraulic Tubes and where rigid Hydraulic Tubes connect to flexible hoses.

5. Hydraulic Tube Maintenance and Repairs:

- Try to position Hydraulic Tubes away from components or parts that require frequent maintenance to reduce interference and maintenance difficulty.

- Label or mark the Hydraulic Tubes for easy identification of their purpose and easy access for inspection and repairs.

6. Ensuring Reliable Hydraulic Tube Connections:

- Use appropriate Hydraulic Tube connection methods such as flanges, threads, or welding to ensure secure and leak-free connections.

7. Compliance with Safety Regulations:

- Adhere to applicable safety regulations and standards to ensure the safety and reliability of the Hydraulic Tubeline system.

The quality and efficiency of Hydraulic Tube layout are closely related to the design, construction, and maintenance. Ensure that qualified professionals are involved in the Hydraulic Tube layout and installation to ensure the sustainability and performance of the system.

Rigid Hydraulic Tube Lines

请输入搜索关键字

确定