NEWS CENTER

Why Pickling and Passivation need for Hydraulic Pipelines?

Why Pickling and Passivation need for Hydraulic Pipelines?

Pickling and passivation are needed for hydraulic pipelines to remove contaminants and enhance corrosion resistance, ensuring reliable and efficient system performance, especially those made from stainless steel.

Hydraulic Pipelines Pickling

1. Removal of Surface Contaminants: During manufacturing, installation, and handling, hydraulic pipelines can accumulate contaminants such as dirt, oil, grease, and metallic residues. Pickling effectively removes these contaminants, ensuring a clean surface.

2. Elimination of Oxide Layers: Welding and other high-heat processes can create oxide layers and scale on the inner and outer surfaces of the pipelines. Pickling removes these oxide layers, which if left untreated, can lead to localized corrosion and reduced efficiency.

3. Improved Surface Finish: Pickling helps in smoothing the surface of the pipelines, reducing surface roughness. This is crucial in hydraulic systems where a smooth internal surface reduces friction and flow resistance, improving the efficiency of fluid movement.

Hydraulic Pipelines Passivation

1. Formation of Protective Oxide Layer: Passivation involves treating the metal surface with a mild oxidant, such as nitric acid or citric acid, to form a thin, protective oxide layer. This layer enhances the natural corrosion resistance of stainless steel by protecting it from environmental factors and contaminants.

2. Enhanced Corrosion Resistance: The protective layer formed during passivation prevents the formation of rust and other forms of corrosion. In hydraulic systems, where pipelines may be exposed to various fluids and environmental conditions, enhanced corrosion resistance ensures longevity and reliability.

3. Prevention of Cross-Contamination: Passivation also helps in removing any free iron particles or other foreign materials from the surface of the stainless steel. This is particularly important in hydraulic systems to prevent cross-contamination of the hydraulic fluid, which can affect the performance and cause damage to the system.

How to Process Pickling and Passivation of Hydraulic Pipelines?

Processing pickling and passivation of hydraulic pipelines involves a series of carefully controlled steps to ensure effective removal of contaminants and formation of a protective oxide layer. Heres a detailed guide on how to carry out these processes:

Hydraulic Pipelines Pickling Process

1. Preparation:

- Safety Measures: Ensure proper personal protective equipment (PPE) is worn, including gloves, goggles, and protective clothing. Work in a well-ventilated area or use fume extraction systems.

- Surface Cleaning: Remove any loose debris, grease, and oil from the pipeline surface using a degreasing agent or detergent. Rinse thoroughly with water.

2. Pickling Solution Preparation:

- Typically, pickling solutions contain a mixture of acids such as nitric acid, hydrofluoric acid, or sulfuric acid. The concentration of these acids should be appropriate for the material and the extent of oxide layer removal needed.

- For stainless steel, a common pickling solution might be 10-15% nitric acid and 1-5% hydrofluoric acid.

3. Application:

- Immersion Pickling: Submerge the pipeline or components in the pickling solution for a specified duration, typically ranging from a few minutes to several hours depending on the extent of surface contamination.

- Brush or Spray Pickling: Apply the pickling solution using brushes or spray systems for larger or fixed installations. Ensure even coverage.

4. Rinsing:

- Thoroughly rinse the pipeline with deionized or clean water to remove all traces of the pickling solution. This step is crucial to prevent residual acid from causing damage.

5. Neutralization:

- Neutralize any remaining acidic residues by rinsing with a neutralizing agent, such as a dilute solution of sodium bicarbonate or another appropriate neutralizer. Follow with another thorough rinse with clean water.

Hydraulic Pipelines Passivation Process

1. Surface Preparation:

- Ensure the pipeline is thoroughly cleaned and rinsed after pickling. The surface should be free of any contaminants or residues.

2. Passivation Solution Preparation:

- Passivation solutions typically contain nitric acid (20-50% concentration) or citric acid solutions. Nitric acid passivation is common for stainless steel, while citric acid is a safer and more environmentally friendly alternative.

3. Application:

- Immersion Passivation: Submerge the pipeline or components in the passivation solution for a specified time, usually 30 minutes to 2 hours.

- Brush or Spray Passivation: Apply the passivation solution evenly using brushes or spray systems, ensuring complete coverage.

4. Rinsing:

- Rinse the pipeline thoroughly with deionized or clean water to remove any residual passivation solution. This helps in ensuring no chemical residues remain that could affect the performance of the pipeline.

5. Drying:

- Allow the pipeline to air dry in a clean, contamination-free environment. Ensure the surface is completely dry before putting the pipeline back into service.

Final Inspection

1. Visual Inspection: Check the pipeline for any signs of discoloration, residue, or remaining contaminants. The surface should appear uniform and clean.

2. Surface Testing: Conduct tests such as the water-break test (water should sheet off a clean surface) or specific passivation verification tests to ensure the effectiveness of the passivation layer.

3. Documentation: Record all steps, solutions used, times, and observations during the process for quality control and future reference.

Considerations for Pickling and Passivation of Hydraulic Pipelines:

1. Safety First: Acidic solutions and other chemicals used in the process are corrosive. Wear appropriate protective gear and ensure good ventilation during operations.

2. Professional Operation: It is advisable to have experienced professionals conduct Pickling and passivation to ensure accuracy and safety.

3. Material Compatibility: Ensure that the selected Pickling and passivating agents are compatible with the materials of the hydraulic pipeline to prevent unnecessary damage.

4. Thorough Rinsing: After each step, thoroughly rinse the pipeline to ensure the removal of residual chemical substances.

5. Environmental Considerations: When handling Pickling solutions and other waste liquids, comply with environmental regulations and adopt proper disposal methods.

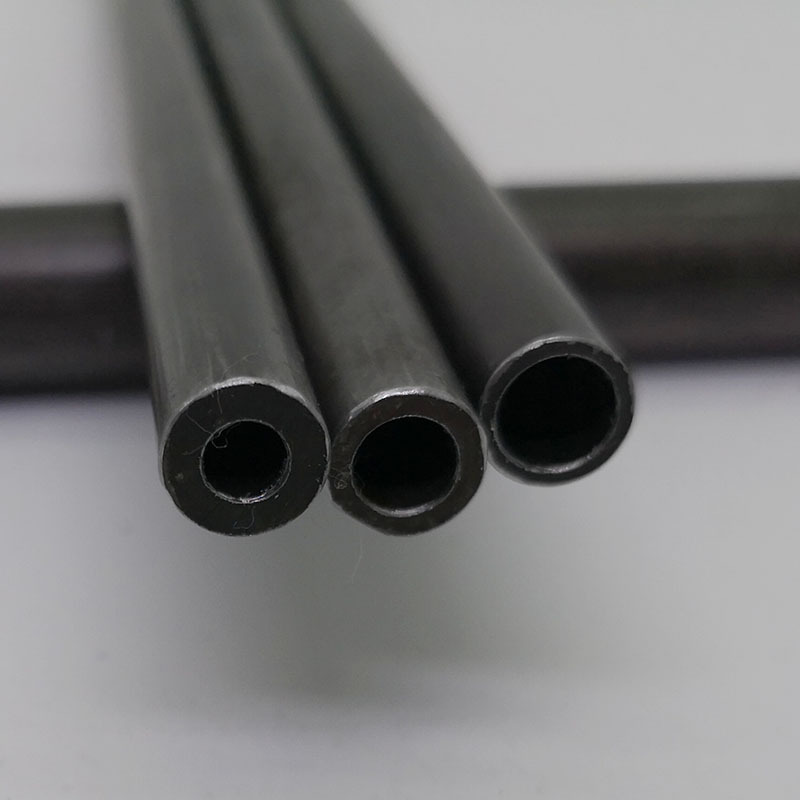

Hydraulic Steel Pipeline

请输入搜索关键字

确定