NEWS CENTER

DIN2391 High Precision Cold Drawn Bright Precision Seamless Steel Tube

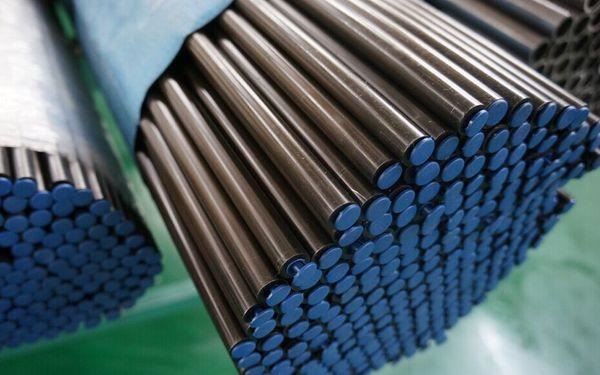

DIN2391 High Precision Cold Drawn Bright Precision Seamless Steel Tube

DIN2391 precision tubes are renowned for their high dimensional accuracy, superior surface finish, and excellent mechanical properties. These tubes are essential in applications requiring high precision and reliability, such as hydraulic systems and automotive components.

DIN2391 is a standard specification for seamless precision steel tubes for mechanical and automotive engineering purposes. These tubes are typically cold drawn and have precise tolerances in terms of dimensions and surface quality. The "bright" finish refers to the surface finish of the tube, indicating a smooth and shiny appearance. These tubes are widely used in various industries where precision and reliability are crucial, such as automotive components, hydraulic systems, and instrumentation. The cold drawing process ensures tight dimensional tolerances and enhances the mechanical properties of the steel, making it suitable for highperformance applications.

DIN2391 Seamless Steel Tube Detailed Manufacturing Process

1. Material Selection:

Steel Grades: Predominantly use St35, St45, and St52.

Properties: Selected for optimal tensile strength, ductility, and toughness.

2. Cold Drawing Process:

Precision Drawing: Tubes are drawn through a die, reducing diameter and enhancing uniformity.

Tolerance Control: Achieves tight tolerances, ensuring consistency in dimensions.

3. Heat Treatment (Bright Annealing):

Bright annealing is a heat treatment process conducted in a protective atmosphere (such as hydrogen, ammonia decomposition gas, or nitrogen) to heat metal materials to a specific temperature (typically between 800 and 950 degrees Celsius), maintain that temperature for a certain period, and then cool them slowly. This process prevents the metal surface from coming into contact with oxygen in the air, thereby avoiding oxidation and keeping the surface bright and clean. Simultaneously, it eliminates residual stress within the material through heating and slow cooling, restoring its plasticity and toughness, thereby improving the metals mechanical properties and surface quality. Bright annealing is widely used in fields that require high surface quality and mechanical properties, such as hydraulic systems, stainless steel processing, the automotive industry, and the aerospace industry.

4. Surface Treatment:

Phosphating: Applied to enhance corrosion resistance.

Polishing: Provides a smooth surface finish, reducing friction in applications.

5. Quality Assurance:

NonDestructive Testing: Includes ultrasonic and eddy current testing for detecting internal and surface defects.

Dimensional Inspection: Ensures compliance with DIN2391 standards for dimensional accuracy and surface quality.

DIN2391 Seamless Steel Tube Characteristics

Dimensional Accuracy: Essential for highperformance applications.

Surface Finish: Reduced surface roughness enhances performance.

Mechanical Strength: High tensile strength and fatigue resistance.

Corrosion Resistance: Phosphating and other treatments extend tube life in harsh environments.

DIN2391 Seamless Steel Tube Applications

1. Hydraulic Systems:

HighPressure Tubing: Used in hydraulic lines and control systems.

Cylinders and Actuators: Critical components in hydraulic machinery.

2. Automotive Industry:

Shock Absorbers: Precision tubes ensure consistent performance under dynamic loads.

Fuel Injection Systems: High precision ensures optimal fuel flow and efficiency.

Drive Shafts: Reliable under high rotational speeds and torque.

3. Industrial Equipment:

Machinery: Components requiring high precision and strength.

Tools: Enhanced durability and accuracy in manufacturing tools.

DIN2391 Seamless Steel Tube Advantages

Operational Efficiency: Improved performance and reduced maintenance.

Extended Lifespan: Superior materials and treatments increase durability.

Versatility: Available in various sizes and specifications for diverse applications.

High Precision Cold Drawn Tube

请输入搜索关键字

确定