NEWS CENTER

Hydraulic Tube Diameter Pressure Comparison

Hydraulic Tube Diameter Pressure Comparison

Hydraulic technology is a method that utilizes the transmission of energy through fluids and controls motion. In hydraulic systems, tube diameter and pressure are two crucial parameters. This article will revolve around these two parameters, exploring the relationship between Tube diameter and pressure in hydraulic technology.

I. Selection of Hydraulic Tube Diameter

The hydraulic Tube diameter refers to the diameter of tubes in a hydraulic system. In a hydraulic system, the choice of Tube diameter directly impacts the systems efficiency and performance. In general, the selection of hydraulic Tube diameter should adhere to the following principles:

1. Flow requirements:

Determine the appropriate diameter based on the fluid flow requirements within the system. If the diameter is too small, it can lead to excessive fluid velocity, causing pressure loss and energy wastage. If the diameter is too large, it increases system cost and size.

2. Pressure requirements:

Select an appropriate diameter based on the working pressure requirements of the fluid in the system. Hydraulic tubes must withstand the maximum working pressure required by the system to ensure safe and stable operation.

3. Tube length:

The length of the Tube also has an impact on the choice of diameter. Generally, for longer tubes, a larger diameter is preferred to reduce pressure loss.

4. Tube material:

Common Tube materials used in hydraulic systems include steel tubes, copper tubes, and more. Different materials offer varying strength and pressure resistance capabilities. Choosing the appropriate diameter ensures system safety and reliability.

II. Relationship Between Hydraulic Tube Diameter and Pressure

In hydraulic systems, there is a certain relationship between Tube diameter and pressure. Generally, larger diameters can withstand higher pressures, while smaller diameters can handle lower pressures. This is because the diameter of the Tube affects fluid flow velocity and resistance. Larger diameters reduce fluid flow speed and lower flow resistance, allowing them to withstand higher pressures.

However, the relationship between Tube diameter and pressure is not a simple linear one. In hydraulic systems, Tube design and selection must consider multiple factors, including fluid flow, working pressure, Tube length, and material. Therefore, in practical applications, reasonable choices should be made based on specific circumstances.

III. Practical Application of Hydraulic Tube Diameter and Pressure

In hydraulic systems, the rational selection of Tube diameter and pressure is crucial for ensuring proper system operation. Lets take an example of a hydraulic system with a working pressure requirement of 20 MPa and a flow rate requirement of 50 L/min. Based on these requirements, the appropriate Tube diameter can be determined through reference tables or calculations.

Using empirical formulas or hydraulic Tube diameter reference tables, it can be determined that a 12 mm diameter is suitable for a flow rate of 50 L/min under a working pressure of 20 MPa. Therefore, in this hydraulic system, a 12 mm diameter can be selected.

After choosing the appropriate diameter, it is also necessary to determine the length and material of the Tube according to actual conditions. Calculate the Tube length based on the system layout and design requirements and select the appropriate Tube material as needed.

Tube diameter and pressure are two essential parameters in hydraulic technology, directly impacting the performance and efficiency of hydraulic systems. Making sensible choices regarding Tube diameter and pressure ensures the safe and stable operation of hydraulic systems. In practical applications, it is necessary to consider factors such as flow requirements, working pressure, Tube length, and Tube material to select the appropriate Tube diameter and pressure. Through correct selection and design, hydraulic system efficiency and reliability can be improved, leading to better performance.

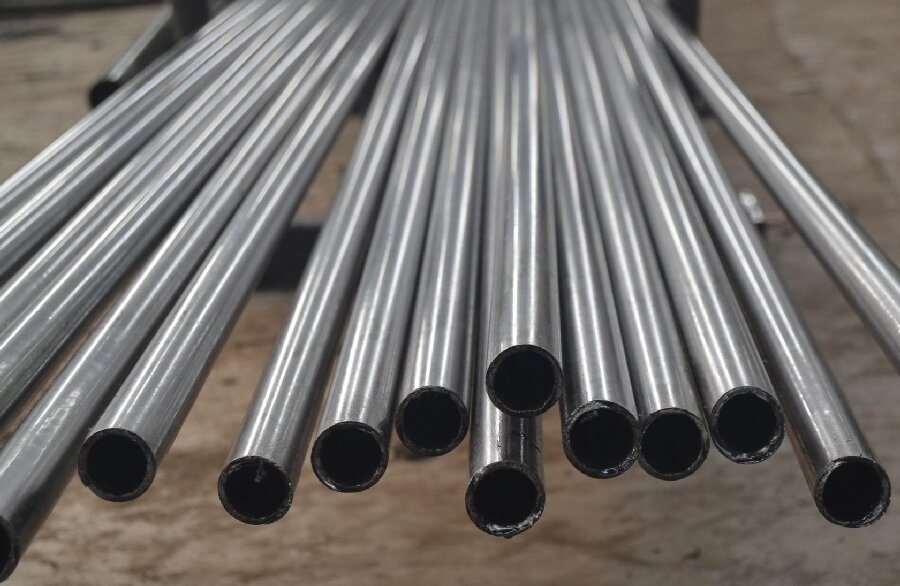

Hydraulic Pressure Tubing

请输入搜索关键字

确定