NEWS CENTER

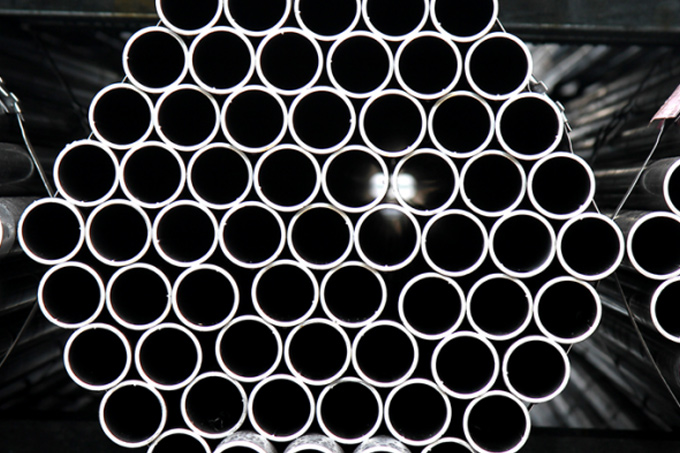

ASTM A513 DOM Tubing (Drawn Over Mandrel)

ASTM A513 DOM Tubing (Drawn Over Mandrel)

Precision Welded Cold Drawn Over Mandrel, commonly known as "DOM Tubing," represents mechanical carbon tubing A513 or DOM pipe. Its important to note that DOM tube is not actually "pipe" despite frequent references to it as such. Leveraging its unique characteristics, DOM Tubing finds application in scenarios demanding exceptional strength-to-weight ratios. Consequently, DOM tubes are utilized as hydraulic cylinders in automotive, 4x4 vehicles, heavy equipment, and agricultural machinery. Their uses extend to a diverse range of components, including plungers, barrels, cylinders, and integral parts of moving components like high-speed shafts for textile and paper mills.

Lordtubing serves as a reliable supplier of DOM tubing, stocking precision steel tubing in various dimensions, including hard-to-find sizes such as heavy wall tubing, large diameter, and smaller sizes.

DOM Mechanical Tubing is the engineers’ choice for where high strength, superior finish, close tolerances, and concentricity are required.

ASTM A513 DOM Steel Tubing Specifications

- ASTM A513 T5

- DOM

- SRA (Stress Relief Annealed)

- Produced OD x ID, 20-24

- Uniform length

- CBQ (Cleaned, Beveled, and Quality)

- Alloy Tube

- Grade C1020

- Grade C1026

Lordtubings A513 DOM Tubing encompasses electric-resistance hot or cold-rolled carbon steel, adhering to specified characteristics such as minimum wall variation, eccentricity, concentricity, resulting in a superior surface with high density and close tolerance.

DOM Tubing Characteristics

- Easy to Weld, Form, Machine, Carburized, and Cut

- Close Tolerances and Mechanical Properties

- Excellent Surface Finish

- Uniform Wall Thickness

FACTS: "DOM" refers to the tubes finishing process and not the metal type. Unlike Seamless Steel Tubes, DOM does have a seam, albeit virtually invisible to the naked eye. The initial manufacturing stage mirrors that of ERW tubing (Electric Resistance Welded); however, unlike ERW, the "Flash" weld is removed and then rolled over a mandrel in the final finishing stage.

Typical Chemical Properties-DOM 1026 Tubing

|

Carbon |

0.22 – 0.28 |

|

Manganese |

0.60 – 0.90 |

|

Phosphorous Max |

0.015 |

|

Sulfur Max |

0.005 |

|

Silicon |

0.10 – 0.25 |

|

Copper |

0.00 – 0.05 |

|

Nickel Max |

0.05 |

|

Chromium Max |

0.05 |

|

Molybdenum Max |

0.05 |

Typical Mechanical Properties – DOM 1026 SRA Tubing

|

Tensile Strength Min |

85,000 psi |

|

Yield Strength Min |

75,000 psi |

|

Elongation Min |

15% |

|

Hardness Min |

80 HRB |

A513 DOM Tubing

请输入搜索关键字

确定