NEWS CENTER

What is high-pressure fuel lines?

What is High-Pressure Fuel Lines?

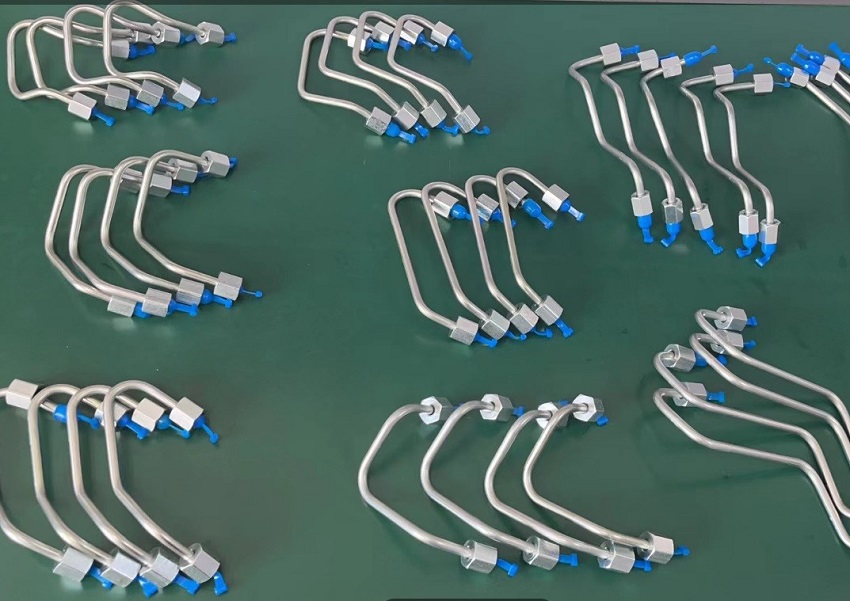

High-Pressure Fuel Lines are essential components of the fuel system in internal combustion engines. Their main function is to transport fuel from the fuel pump to the fuel injectors, supplying high-pressure fuel to be sprayed into the engine cylinders for combustion. This component is frequently found in diesel engines or direct-injection engines, typically used in heavy-duty vehicles, trucks, agricultural machinery, and industrial equipment.

The high-pressure fuel line characteristics and functions:

1. High-pressure resistance:

- High-pressure fuel line must withstand the high pressures typically found in high-pressure fuel injection systems, often exceeding several thousand pounds per square inch (psi). This ensures the fuel is injected into the cylinder at the necessary pressure for efficient combustion.

- High-pressure fuel lines are designed to withstand pressures ranging from 1,500 bar (21,750 psi) in traditional diesel engines to over 3,000 bar (43,500 psi) in advanced direct injection systems.

- These pressures ensure proper atomization of fuel for efficient combustion.

2. Corrosion resistance:

- Given the potential for impurities and corrosive substances in fuel, high-pressure fuel lines are typically made of corrosion-resistant materials to ensure longevity.

- Typically constructed from high-strength stainless steel or other robust alloys to resist corrosion, withstand high pressures, and endure the high temperatures of engine environments.

- Inner coatings or linings may be used to resist the corrosive effects of modern fuel blends, including those with biofuels.

3. Precision in manufacturing and dimensions:

The inner diameter and wall thickness of the high-pressure fuel line require high accuracy to guarantee the precision and stability of fuel injection.

4. Heat resistance:

High-pressure fuel lines are exposed to high-temperature environments when the engine operates, necessitating heat-resistant properties.

5. Sealing performance:

High-pressure fuel lines must be well-sealed to prevent fuel leaks.

6. Wear resistance:

Due to the high-pressure flow of fuel, the interior surface of the high-pressure fuel line needs good wear resistance to prevent damage or wear.

The high-pressure fuel line Function

1. Fuel Delivery:

- High-pressure fuel lines transport fuel from the high-pressure fuel pump to the fuel injectors.

- They play a crucial role in delivering fuel at the precise pressure required for optimal injector performance.

2. Injection Timing and Precision:

- By maintaining consistent high pressure, these lines ensure that injectors can precisely control the timing and amount of fuel injected into the combustion chamber.

- This precision is crucial for achieving efficient combustion, reducing emissions, and improving fuel economy.

The high-pressure fuel line Applications

1. Diesel Engines:

- Commonly used in diesel engines with common rail injection systems, where a single high-pressure fuel line feeds multiple injectors through a common rail.

- These systems operate at pressures often exceeding 2,000 bar (29,000 psi) to achieve fine fuel atomization and efficient combustion.

2. Gasoline Direct Injection (GDI) Engines:

- Employed in GDI systems, where fuel is injected directly into the combustion chamber at high pressure.

- Typical pressures in GDI systems range from 200 to 350 bar (2,900 to 5,000 psi).

High-pressure fuel lines are crucial components in the fuel delivery systems of internal combustion engines, particularly in diesel engines and direct fuel injection systems in gasoline engines. These lines transport fuel from the fuel pump to the injectors at high pressure, ensuring efficient fuel atomization and combustion.

High-pressure fuel lines

请输入搜索关键字

确定