NEWS CENTER

What is steel hydraulic lines?

What is steel hydraulic lines?

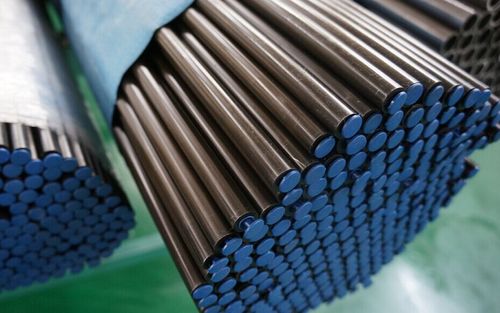

Steel hydraulic lines are pipes or tubes made from steel that are used to transport hydraulic fluid in various hydraulic systems. These systems are commonly found in industrial machinery, automotive brake systems, aircraft, and heavy equipment, among other applications.

Steel hydraulic lines are preferred for their durability, strength, and resistance to corrosion and high pressure. They are designed to withstand the intense pressures and temperatures associated with hydraulic systems without leaking or failing.

1. Steel hydraulic lines Material:

Steel hydraulic lines are typically made from high-strength steel because of its ability to withstand high pressures without bursting.These lines are typically made from high-quality steel alloys such as stainless steel or carbon steel, which provide the necessary strength and resistance to corrosion. They are often precision-engineered to precise specifications to ensure optimal performance and reliability in hydraulic systems.

2. Steel hydraulic lines Construction:

Steel hydraulic lines can either be seamless or welded. Seamless tubes are made by extruding a solid billet into a desired shape without a welded seam, while welded tubes are formed from flat steel that is then welded along the seam.

3. Steel hydraulic lines Advantages:

- Durability: Steel lines are highly durable and can withstand harsh environments.

- High Pressure: Steel lines can handle very high pressures, making them ideal for many hydraulic systems.

- Temperature Resistance: They can handle wide temperature variations.

4. Steel hydraulic lines Disadvantages:

- Corrosion: Without proper protective measures, steel is susceptible to corrosion. To mitigate this, lines are often coated or plated with materials like zinc.

- Weight: Steel lines are heavier than alternatives like aluminum or plastic, which can be a concern in weight-sensitive applications, such as aviation.

- Flexibility: Steel is not as flexible as some other materials, and thus might not be suitable for applications requiring frequent bending or flexing.

5. Steel hydraulic lines Maintenance:

Regular inspections are crucial, especially in critical applications like aviation. Corrosion, damage, and leaks should be addressed immediately to prevent system failures.

6. Steel hydraulic lines Fittings:

Steel hydraulic lines use specialized fittings for connections. These fittings should be appropriately tightened to prevent leaks but not over-tightened as that could damage the line or fitting.

7. Steel hydraulic lines Bending and Routing:

Care should be taken when bending steel hydraulic lines to avoid kinks, which can weaken the line and reduce its carrying capacity. The use of bending tools and ensuring proper bend radii is crucial. Proper routing also helps in preventing excessive vibration and rubbing against other components, which can lead to premature wear.

8. Steel hydraulic lines Safety:

Always ensure the system is depressurized before working on hydraulic lines. Hydraulic fluids under pressure can penetrate the skin and cause serious injuries.

Steel hydraulic lines play a critical role in the functioning of hydraulic systems, providing a reliable means of transmitting hydraulic fluid to power various mechanical components and machinery.

Steel hydraulic lines

请输入搜索关键字

确定