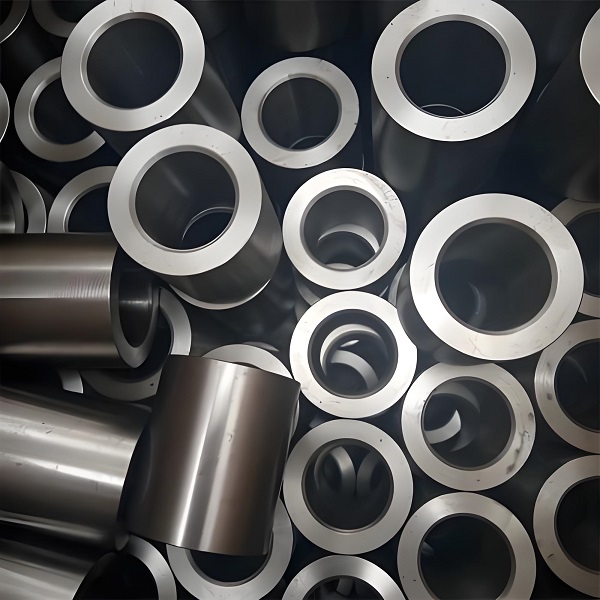

Introduce High-Carbon Chromium Bearing Steel Tube

The most often used steel for making bearings and bearing parts is high carbon chromium bearing steel, which is a significant bearing steel category. The bearings performance and lifespan are directly influenced by the complexity of its manufacturing process.

|

USA |

GB |

JIS |

EN |

|

AISI 52100 |

GCr15 |

SUJ2 |

100Cr6 |

|

Grade |

|

C |

Si |

Mn |

P |

S |

Cr |

Ni |

Mo |

Cu |

O |

Al |

Ca |

Ti |

As |

As+Sn+Sb |

Pb |

|

GCr15 |

GCr15 |

0.95-1.05 |

0.15-0.35 |

0.25-0.45 |

≤0.025 |

≤0.02 |

1.4-1.65 |

≤0.25 |

≤0.1 |

≤0.25 |

≤0.0012 |

≤0.05 |

- |

≤0.005 |

≤0.04 |

≤0.075 |

≤0.002 |

|

GCr15A |

≤0.02 |

≤0.02 |

≤0.0009 |

≤0.001 |

≤0.003 |

||||||||||||

|

GCr15E |

≤0.015 |

≤0.015 |

≤0.0006 |

≤0.001 |

≤0.0015 |

||||||||||||

|

52100 |

|

0.93-1.05 |

0.15-0.35 |

0.25-0.45 |

≤0.025 |

≤0.015 |

1.35-1.6 |

≤0.25 |

≤0.1 |

≤0.3 |

≤0.0015 |

≤0.05 |

- |

- |

- |

- |

- |

|

SUJ2 |

|

0.95-1.1 |

0.15-0.35 |

≤0.5 |

≤0.025 |

≤0.025 |

1.3-1.6 |

≤0.25 |

≤0.08 |

≤0.25 |

- |

- |

- |

- |

- |

- |

- |

|

100Cr6 |

|

0.9-1.05 |

0.15-0.35 |

0.25-0.45 |

≤0.03 |

≤0.025 |

1.35-1.65 |

≤0.3 |

- |

≤0.3 |

- |

- |

- |

- |

- |

- |

- |

|

Grade |

Hardness after Annealing |

|

GCr15 |

179-207 HBW |

|

52100 |

60-67 HRC |

|

SUJ2 |

≤201 HBW |

|

100Cr6 |

187–229 HBS |

High-Carbon Chromium Bearing Steel Tube

请输入搜索关键字

确定